5 Axis Vertical Machining center

Minnuo 5 axis machining center, with excellent precision andefficiency, to meet your needs for complex parts machining.

- High Precision and Complex Machining

- Reduced Setup Time and Increased Efficiency

- Superior Surface Quality

- Versatility and Flexibility

5 Axis Vertical Machining center

- High Precision and Complex Machining

- Reduced Setup Time and Increased Efficiency

- Superior Surface Quality

- Versatility and Flexibility

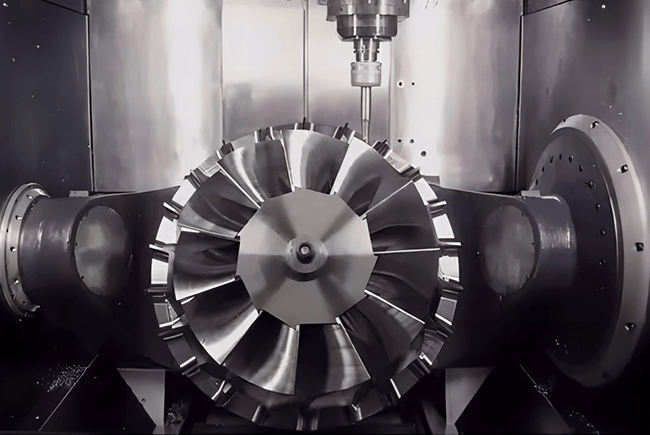

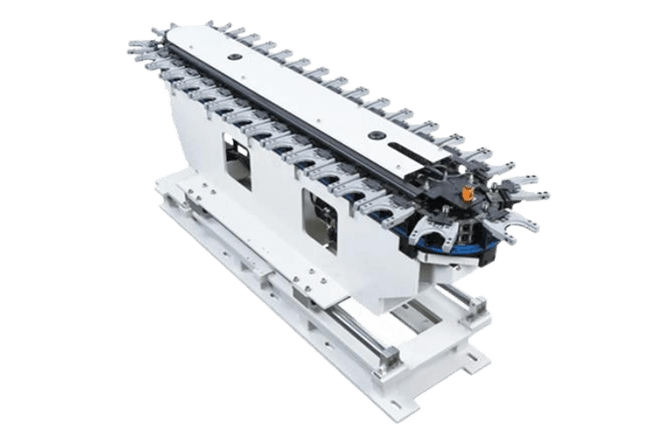

VDU & VDW Series

5-axis vertical machining center adopts gantry improved three coordinate structure with two-axis composite rotary table to realize 5-axis linkage machining. The machine tool uses finite element analysis means, combined with the center of gravity drive, lightweight design concept, in the space of compact structure, both enhance the rigidity of the machine tool and improve the dynamic performance of the machine tool.

- Table maximum load: 600kg

- X/Y/Z axis travel: 650/650/500mm

- Spindle speed: 2800-4000 per minute

High speed— —High precision——High rigidity

★ Rapid traverse speed of linear axis 45m/min, option 60m/min.

★ 12000rpm direct-connected spindle, a variety of speed spindle can be selected (15000rpm direct-connected main, axis 20000rpm electric spindle).

★ The spindle utilizes IRD dynamic balance correction equipment to directly correct the dynamic balance of the spindle, so that when the spindle is running at high speeds, it avoids resonance phenomena and ensures the best machining accuracy. The spindle is equipped with oil cooling as standard.

★ Various tool changer capacities are available (20, 30, 40, 50, 60).

★ High precision ball screw drive structure. High rigidity roller guideway. Positioning accuracy 0.006, repeat positioning accuracy 0.004.

★ Spindle direct access type tool changer, tool change time (tool to tool) 8 s.

★ A/C-axis composite rotary table, configured with angle grating to realize closed-loop position feedback for both axes, positioning accuracy repeatability 4″.

★ The main part of the machine tool all adopts resin sand high-strength castings, and the bed is a whole wall casting.

★ All three axes adopt high rigidity roller guideway.

★ All castings are designed by finite element analysis.

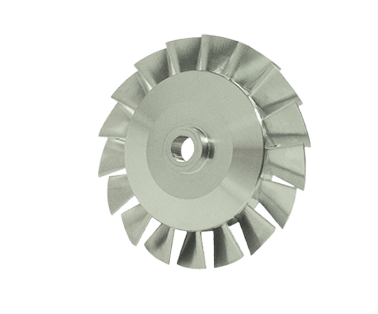

Presentation of perfect workpieces

Choose Minnuo 5-axis CNC machining centers to enjoy extraordinary machining efficiency and precision! Specialized for precision manufacturing, it is widely used in aviation, aerospace, military and other high-end fields to meet the needs of precision machining of complex parts.

Choosing the type of machine you want

To select the type of machine tool that meets your requirements, you can consider the following aspects:

- What materials will you be working with? (e.g., metals, plastics)

This helps determine the appropriate cutting tools and machine specifications needed.

- What are the maximum and minimum sizes of workpieces? (e.g., diameter, length)

- What level of precision and tolerance do you require?

- What specific operations do you need the lathe to perform? For example, turning, threading, drilling, or knurling.

- Are there any specific features or attachments you require, such as a digital readout, variable speed control, or specialized chucks? (e.g., variable speeds, digital readout)

- What is your budget for the lathe?

- Do you need any specific after-sales support or service, such as maintenance, training, or warranty coverage?

This ensures the lathe can accommodate your requirements.

This will help in selecting a lathe with the appropriate accuracy and control features.

This will help in choosing a lathe with the necessary capabilities and features.

cost

Shipping and Receiving Support, etc.

Post-delivery service you must be concerned about

No Worries After Sales

From professional technical consultation to rapid response on-site support, Minnuo is committed to providing you with a full range of after-sales protection. No matter when and where, your satisfaction is our eternal pursuit. Choose Minnuo, choose worry-free after-sales service experience!

WARRANTY

1-year warranty for equipment and 3-year warranty for system

GUIDANCE

Lifetime free 24/7 technical consultation & guidance

TURNKEY

Order more than ten units and get full on-site service from our engineers

Minnuo's Manufacturing Strengths

Minnuo machine tools, enjoy ISO9001 quality, better price, help enterprises to develop efficiently!

Jiangsu Minnuo Group Co., Ltd., a leading provider of CNC machine tools and intelligent manufacturing solutions, has been dedicated to the research and manufacturing of CNC machine tools, flexible manufacturing systems, and automated complete sets of technologies and equipment since its establishment.

Made in China factory, everything is in accordance with ISO9001 standards

30 years of experience in metal processing equipment manufacturing

Our Vision

Advanced Manufacturing and Technical Services

Building a world-class high-end machine tool and equipment group Building the "main role" to undertake the national strategy To serve the strategy of a strong manufacturing country, to develop high-end machine tool industry as the Group's political mission and the first core business, to take the initiative to carry the banner of revitalization and development of China's machine tool industry, to become a leader in promoting China's machine tools to the mid-range and high-end, and to build the world's top high-end machine tool and equipment group with its own core technology and global competitiveness.

Trade and Engineering Services

Constructing "Main Force" for High Quality Introduction and High Level Going Out Create "active energy" for the Group to grow stronger and bigger. Committed to the prosperity of trade, Minnuo Machine Tool takes the mission of promoting industrial upgrading to build a machine tool trade platform integrating precision machining, technological innovation, education and training, and after-sales service, and to build an industrial ecosystem covering various fields such as machinery manufacturing, automobile and shipbuilding, aerospace and intelligent manufacturing, etc., and strives to become a leading machine tool and trade solution provider in the world and a first-class one in China.