Slant-bed CNC Lathe

Strong rigidity/Easy chip removal/Area saving

Minnuo,a leading manufacturer in China with 37 years of experience.To provide you with unparalleled machining accuracy and production efficiency to meet the processing needs of various complex parts.

PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Related News

Slant-bed CNC Lathe

Slant bed CNC lathe is a kind of high precision and high efficiency automatic machine tool. Equipped with multi-station turret or power turret, the machine tool will have a wide range of process performance, and can process linear cylindrical, oblique cylindrical, circular arc and various threads, grooves, worm gears and other complex workpieces, with linear interpolation, circular arc interpolation of various compensating functions, and play a good economic effect in the mass production of complex parts.

CNC slant-bed lathes are also ideal for automotive, aerospace, medical and abrasive manufacturing, ensuring consistent stability and productivity.

Minnuo, as a professional CNC slant bed manufacturer and supplier, we have a first-class machinery manufacturing factory, focusing on the research, development, manufacturing and sales of various intelligent manufacturing and automation complete sets of technology and equipment.

CNC slant bed structure diagram

Slant bed CNC lathe machine Structure Feature

1.

High-rigidity structure design

The bed adopts integral casting molding, and the bed guideway is 45° inclined layout,which has a large load-bearingcross-section, good rigidity and vibration-absorbing properties, and can ensure high-precision cutting processing

2.

High-efficiency, low-noise design

The main transmission system of the machine tool adopts AC servo motor drive, with high-efficiency parallel V-belt direct drive spindle. Avoid the noise problem caused by the gear box transmission chain.

3.

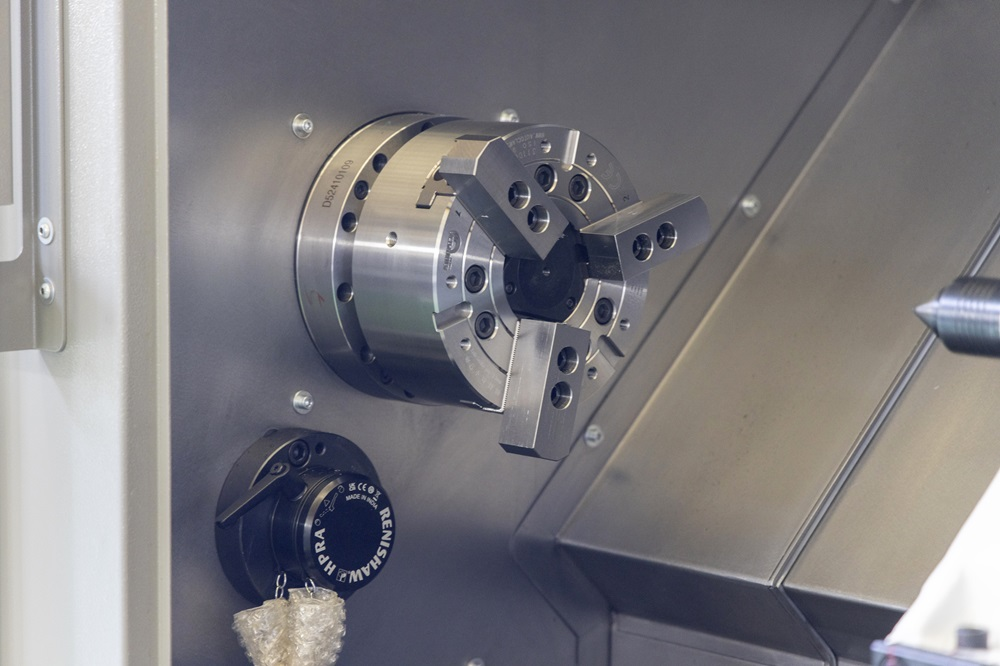

High speed, high rigidity spindle

Spindle front and rear ends with NSK precision high-speed spindle bearing set, and apply appropriate preload, with the ideal span support and box spindle box, so that the spindle has a high rigidity and high-speed operation ability

4.

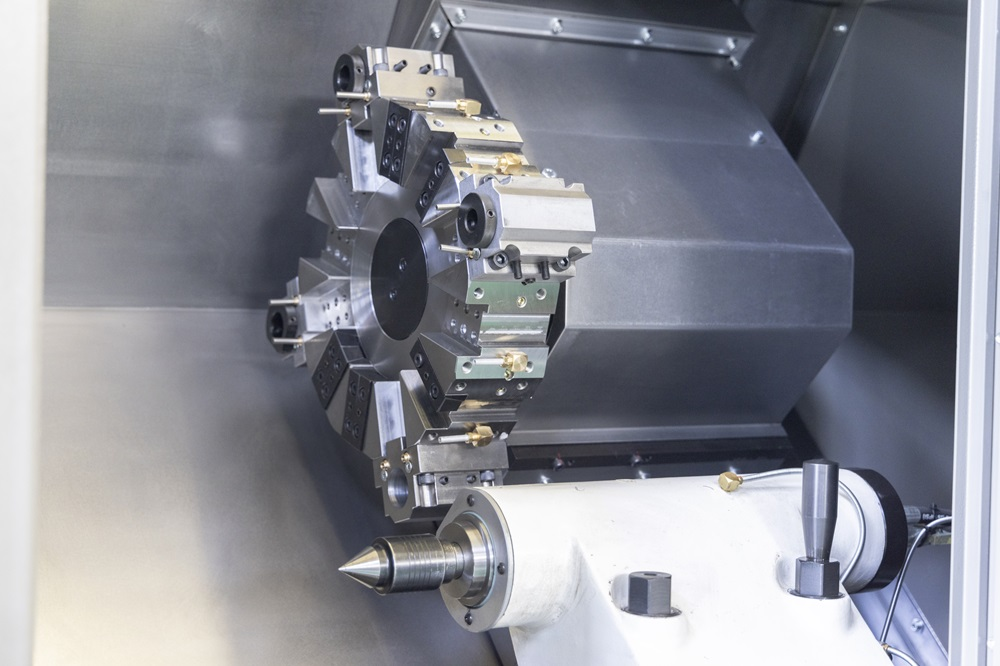

Highly reliable tool holder

Equipped with high rigidity hydraulic tool turret, it has high reliability and repeatable positioning accuracy.provide accurate centering guarantee for turning processing.

Which CNC lathe to choose ?

Flat bed or Slant bed

- Machine Layout: The plane where the guideway of a flat bed lathe is located is parallel to the ground, and the plane where the guideway of a slant bed is located is at an angle to the ground (generally 30°, 45°, 60° and 75°). This makes the X-axis drag plate of slant-bed lathe longer than that of flat-bed lathe under the width of the compatible guideway, which can be arranged with more number of tool positions.

- Cutting Rigidity: The cross sectional area of slant bed is larger than flat bed, so it can provide stronger resistance to bending and twisting; moreover, during the cutting process, the cutting direction of the tool and the direction of gravity of the workpiece are the same, which is not easy to cause vibration, and the spindle operation will be smoother, whereas in the case of flat bed CNC lathe, as the cutting force and the gravity of the workpiece are at 90°, it is more likely to cause vibration, which affects the accuracy of the workpiece.

- Machining accuracy: The design of slant-bed CNC lathe can directly reduce the backlash of the ball screw in the X-axis direction, because gravity acts on the axial direction of the screw, which almost eliminates the backlash and thus improves the machining accuracy. While the flat bed CNC lathe’s X-direction silk rod is not affected by axial gravity, the clearance is difficult to eliminate directly, which may affect machining accuracy.

- Chip removal ability: slant-bed CNC lathe is more conducive to chip removal due to its inclined guideway design, and it is not easy to produce the problem of chip wrapping around the tool. Usually configured with automatic chip removal machine, can automatically remove chips, increase the effective working time of workers. And the structure of flat bed CNC lathe has disadvantage in automatic chip removal, it is difficult to add automatic chip conveyor.

- Automated production: the structure of slant-bed CNC lathe is more conducive to the realization of automated production, can be added to the milling power head, automatic feeding machine tools or robots, to achieve automatic loading, unloading and chip removal, so as to improve work efficiency. In contrast, flat bed CNC lathe has certain limitations in automated production.

Application areas and parts

- Aerospace: Used for machining high-precision components such as aircraft engine parts and structural elements.

- Automotive Industry: Employed in the production of automotive components, including engine parts, transmission systems, and brake system components.

- Mold Manufacturing: Utilized for machining precision mold parts, including injection molds and stamping dies.

- Medical Devices: Applied in the machining of high-precision components for medical equipment.

- Electronics Industry: Used to machine precise parts for electronic devices, such as connectors and circuit boards.

- Energy Sector: Involved in the machining of components for oil, gas, and renewable energy equipment.

- Military Industry: Used to produce high-precision parts for military equipment.

- General Machining: Suitable for the mass production and precision machining of various general mechanical parts.

Side is our machine debugging video, for reference as well as if you have no way to determine whether your workpiece can choose flat bed CNC lathe processing, you can consult our engineers, give the workpiece drawings or specific workpiece can be.

How We Support You Before Your Purchase Decision ?

Technical Support

Our team provides comprehensive technical support tailored to your machining needs. We offer the best solutions and recommendations to help you optimize your production processes and increase efficiency.

Quick Response

Our sales team is committed to responding to your inquiries within 24 hours. We promptly address your questions and concerns to ensure you have all the information you need.

Customized Solutions

We offer customized product configurations and solutions based on your specific requirements. Whether you need special attachments, software, or unique configurations, we are here to meet your specific machining needs.

Professionalism and Integrity

With years of industry experience, our professional team is dedicated to providing you with the highest quality pre-sales service. We uphold the values of professionalism and integrity, ensuring you receive reliable and trustworthy support.

Why Choose MINNUO Machine Tools ?

Minnuo Group Co., Ltd. has established two modern industrial bases covering an area of 200,000 square meters.These bases focus on the research, development, and manufacturing of CNC machine tools, flexible manufacturing systems, automated complete sets of technology and equipment, as well as the industrialization of functional components. The current equipment inventory comprises nearly 2500 units of equipment, including “primary, large, precision, and rare” categories, along with over 80 effective patents. The company serves over 100 countries and regions globally in industries such as automobiles, rail transit, construction machinery, oil machinery, mining and metallurgy, communication equipment, and vocational education, providing high-quality products, services, and comprehensive solutions.

Our Manufacturing Process and Quality Control

- 1. Rigorous Quality Checks at Every Stage

- 2. State-of-the-Art Manufacturing Facilities

- 3. Skilled Technicians and Engineers