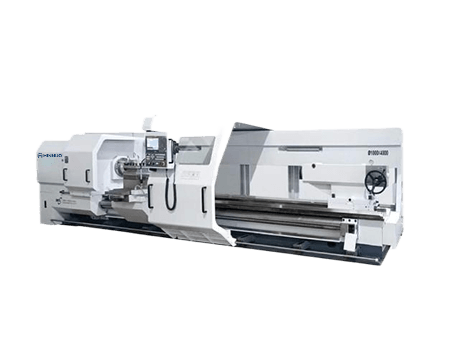

Flat-bed CNC Lathe

Minnuo,A Leading Manufacturer In China With 37 Years Of Experience.To Provide You With Unparalleled Machining Accuracy And Production Efficiency To Meet The Processing Needs Of Various Complex Parts.

- Siemens, Fanuc and other well-known CNC systems

- Multi-axis machining

- Full Support Service

PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Related News

Flat-bed CNC Lathe

Flat bed CNC lathe is a high precision, high rigidity metal cutting machine tool designed for automation and precision machining of rotating body parts. It adopts sturdy box way flat bed structure to provide a stable machining platform, reduce vibration and ensure machining accuracy. Equipped with advanced CNC system, it supports automatic tool change and automatic feeding to improve productivity. It is suitable for compound machining such as turning, milling, drilling and tapping of various metal materials, and is widely used in automobile, aerospace, machinery manufacturing and other industries.

Flat bed lathe

structure and characteristics

Usually flat bed CNC lathe has 11 structural components, in addition to the 5 important structures listed below, there are worktable, feeding system, drive system, hydraulic system, cooling system, lubrication system, chip conveyor.

Strong adaptability

suitable for multi-species, small and medium batch production, especially for complex, high-precision parts processing has superiority.

Spindle box

Containing spindle and its driving system, it is the core component to realize the rotation of the workpiece, which directly affects the precision and efficiency of turning processing. We adopt high-speed, high-precision, high-rigidity mechanical spindle to ensure the precision and efficiency of machining, which can realize 3-gear spindle speed, step-less in gear.

CNC system

As the control center of the machine tool, it is responsible for receiving the machining program instruction and controlling the coordinated action of each part of the machine tool to realize automatic machining. We can provide common systems on the market, including GSK, Fanuc, Siemens, HNC, KND, Mitsubishi and so on.

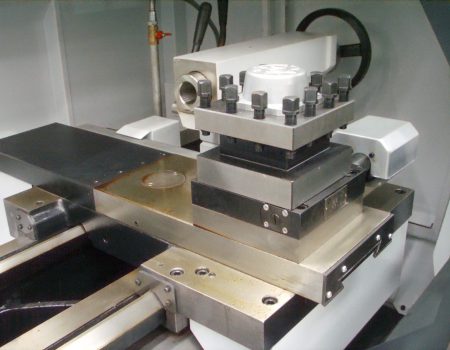

Tool holder

used for fixing and adjusting various cutting tools, support multi-station automatic tool change, improve processing diversity and efficiency. Vertical 4-station tool holder is standard, and horizontal 6/8-station tool holder is optional.

Bed

As the foundation of the entire machine tool, providing stability and load-bearing capacity, we Minnuo use high-strength cast iron with resin sand casting to ensure the stability of the machine tool operation, durability and high rigidity.

Overall design

the machine adopts the conventional horizontal lathe layout, and the overall design is well sealed and meets the safety standards .

For how to choose our products, we have compiled some differences for you

How to Choose?

Flat Bed CNC Lathe Advantages

① Classic Layout

Our flat bed CNC lathe features a traditional horizontal guide rail design, renowned for its stability and reliability. It provides a solid and stable machining platform, especially suited for applications where precision and stability are paramount.

② Ease of Operation and Maintenance

The simple and intuitive design of the flat bed lathe allows operators to quickly become proficient, and it is also easier to maintain. This user-friendly design reduces training time and increases production efficiency.

③ Cost-Effectiveness

While maintaining high performance, the flat bed CNC lathe offers a highly competitive price. It is an excellent value-for-money option, particularly for businesses with limited budgets but stringent requirements for machining quality.

④ Outstanding Machining Accuracy

Although slant bed lathes offer advantages in certain areas, flat bed lathes also excel in precision machining. Our lathes ensure superior machining accuracy and surface finish through precise manufacturing processes and advanced control systems.

⑤ Flexible Automation Solutions

While flat bed lathes may not inherently support certain automation features as readily as slant bed lathes, we offer a range of flexible automation options, including custom chip evacuation systems and automated accessories, to meet your specific needs.

⑥ Versatile Application Suitability

Flat bed CNC lathes are suitable for various metalworking fields, providing stable and reliable machining performance in both mass production and small batch production.

Slant Bed CNC Lathe Advantages

① Optimized Cutting Rigidity

The design of the slant bed CNC lathe excels in withstanding cutting forces. Due to its structural

② Precise Machining Accuracy

The X-axis ball screw design of the slant bed lathe helps to reduce backlash, ensuring more precise cutting in tasks that demand high accuracy.

③ Efficient Chip Evacuation System

Slant bed lathes are typically equipped with efficient chip evacuation systems, which help keep the cutting area clean, thereby improving machining efficiency and extending tool life.

④ Potential for Automated Production

The design of the slant bed lathe makes it easier to integrate automation components such as automatic loading and unloading systems. This can significantly enhance production efficiency and reduce the need for manual intervention.

⑤ Adaptability to Complex Machining

The inclined design of the slant bed lathe is advantageous for handling complex or hard-to-reach machining areas, making it particularly beneficial for processing specific types of parts.

Free customer experience guide

When comparing slant bed and flat bed CNC lathes, you may find that slant bed lathes offer additional advantages in certain aspects. However, the final decision on which lathe to choose depends on your specific needs, budget, and the particular demands for production efficiency and machining accuracy. Flat bed lathes also hold a strong position in the market due to their cost-effectiveness, ease of use, and ease of maintenance. We recommend selecting the lathe type that best aligns with your machining requirements and long-term goals.

If you’re unsure about which lathe to choose, feel free to contact our engineers for a professional consultation!

Machinable Workpieces

Flat-bed CNC lathe is widely used in the field of machining, especially suitable for processing medium and small disk and cover parts, suitable for the production of multi-species, small and medium batch products.

Disk parts

diameter greater than the length of the rotating body parts, such as flywheels, gears, flange, etc.. Mainly for turning the outer circle, turning the inner hole, end face processing.

Circular arc parts

Parts with rounded surfaces, such as spherical bearings and rounded gears. The lathe can process various radii of the arc-shaped surface.

Complex rotary parts

parts with multiple steps, curved contours or complex internal cavities, such as valve housings, complex couplings and so on. CNC lathe can process these complex shapes through multi-axis linkage.

Taper parts

e.g. tapered pins, tapered shafts, etc. Lathes can perform taper turning to form tapered surfaces.

Sleeve parts

parts with internal and external cylindrical surfaces, such as bushings, bushings, pipe fittings, etc. The lathe can perform operations such as internal hole turning, external turning and thread turning.

Threaded parts

e.g. screws, nuts, screws, etc. Lathes can process both external and internal threads.

Shaft parts

rotating body parts with length greater than diameter, such as transmission shafts, couplings, etc.. Lathe can be rough turning, fine turning, groove cutting, turning threads and other operations.

If you do not know how to choose the right lathe for your workpiece, we have professional engineers who can assist you and give you the best guidance to assist you in your selection.

How We Support You Before Your Purchase Decision ?

Technical Support

Our team provides comprehensive technical support tailored to your machining needs. We offer the best solutions and recommendations to help you optimize your production processes and increase efficiency.

Quick Response

Our sales team is committed to responding to your inquiries within 24 hours. We promptly address your questions and concerns to ensure you have all the information you need.

Customized Solutions

We offer customized product configurations and solutions based on your specific requirements. Whether you need special attachments, software, or unique configurations, we are here to meet your specific machining needs.

Professionalism and Integrity

With years of industry experience, our professional team is dedicated to providing you with the highest quality pre-sales service. We uphold the values of professionalism and integrity, ensuring you receive reliable and trustworthy support.

Why Choose MINNUO Machine Tools ?

Minnuo Group Co., Ltd. has established two modern industrial bases covering an area of 200,000 square meters.These bases focus on the research, development, and manufacturing of CNC machine tools, flexible manufacturing systems, automated complete sets of technology and equipment, as well as the industrialization of functional components. The current equipment inventory comprises nearly 2500 units of equipment, including “primary, large, precision, and rare” categories, along with over 80 effective patents. The company serves over 100 countries and regions globally in industries such as automobiles, rail transit, construction machinery, oil machinery, mining and metallurgy, communication equipment, and vocational education, providing high-quality products, services, and comprehensive solutions.

Our Manufacturing Process and Quality Control

- 1. Rigorous Quality Checks at Every Stage

- 2. State-of-the-Art Manufacturing Facilities

- 3. Skilled Technicians and Engineers