CNC machines are capable of performing a variety of machining tasks and have a broad range of application adaptability.The types, models, functions, and drive systems of machine tools all exhibit diversity.We also categorize their precision levels.

We reflect the diversity of CNC machine types in different machining processes, motion trajectories, and drive mechanisms. Model diversity includes a variety of horizontal, vertical, slant-bed CNC lathes, milling machines, machining centers, and grinders. Functional diversity allows CNC machines to accomplish various machining tasks such as milling, turning, drilling, threading, and grinding, while the diversity of drive systems encompasses drive methods, motor types, control units, feedback detection, and transmission mechanisms. We categorize the diversity of precision levels based on national standards to ensure that the parts produced meet the required specifications.

First, we understand the diversity of types, which are commonly classified in the following ways:

Classify types by CNC machine tool processes:

•Metal Cutting CNC Machine Tools

Corresponding to traditional machining processes like turning, milling, drilling, grinding, and gear cutting, we have CNC lathes, CNC milling machines, CNC drilling machines, CNC grinding machines, and CNC gear machines. Although these CNC machines differ greatly in their methods, their movements and actions are digitally controlled, offering high efficiency and a high degree of automation. At present, we also have precision metal sheet laser cutters.

•Specialty Process CNC Machine Tools

In addition to machining CNC machines, CNC is also widely used in CNC wire electrical discharge machines, CNC electric spark forming machines, CNC plasma arc cutting machines, CNC flame cutting machines, and CNC laser machines.

•Sheet Metal Stamping CNC Machine Tools

Common CNC machines used for sheet metal stamping include CNC presses, CNC shears, and CNC bending machines.

Classify types by controlled motion trajectories:

•Point-to-Point CNC Machine Tools

CNC systems of these machine tools control only the endpoint coordinates of the travel, not the trajectory between points, so there is no connection between the movements of the various coordinate axes. Such CNC machines mainly include CNC coordinate boring machines, CNC drilling machines, CNC punching machines, and CNC spot welders.

•Linear Control CNC Machine Tools

Linear control CNC machine tools enable the control of the tool or worktable to move and cut along directions parallel to the coordinate axes at appropriate feed rates. These feed rates can vary within a certain range depending on the cutting conditions. For instance, we use simple linear control CNC lathes, which possess only two coordinate axes, for machining stepped shafts. Similarly, we utilize linear control CNC milling machines, equipped with three coordinate axes, for planar milling tasks.

•Contour Control CNC Machine Tools

Contour control CNC machine tools can continuously and interrelatedly control the displacement and speed of two or more movements, enabling the composite motion trajectory in plane or space to meet the contour requirements of the part. Typical examples are common CNC lathes, CNC milling machines, and CNC grinding machines.

Classify types by characteristics of the drive system:

•Open-loop Control CNC Machine Tools (CNC Precision Horizontal Boring and Milling Machines)

These CNC machines operate with a control system that lacks position detection components, and the driving components are typically stepper motors. We design the information flow in such CNC machines to be one-way, which is why we call them open-loop control CNC machines.

They are suitable only for medium and small CNC machines that do not require high precision, especially simple CNC machines.

•Closed-loop Control CNC Machine Tools

We detect the actual displacement of the worktable, feed the measured displacement value into the CNC device, compare it with the input command displacement value, and use the difference to control the machine tool, ultimately achieving precise movement of the moving parts. We refer to such CNC machines, which have the worktable included in the control loop, as closed-loop control CNC machines.

Adapting to and completing a range of different machining tasks, the diversity of CNC machine functions is indispensable.

Lathe/Milling Machine

For example,CNC milling machines can accomplish milling tasks from flat surfaces to complex 3D curved surfaces by using end mills of various shapes and sizes. Meanwhile, CNC lathes focus on turning operations for rotating workpieces, including external circles, internal holes, grooves, and threads. The threading function, integrated into CNC lathes, milling machines, or machining centers, enables CNC machines to produce internal or external threads on parts.

Grinding Machine

CNC grinding machines utilize abrasive tools like grinding wheels to excel in precision machining, capable of performing surface grinding, external cylindrical grinding, internal cylindrical grinding, and centerless grinding, achieving very high surface finish and dimensional accuracy.

Boring Machine

We use CNC boring machines for hole and flat surface machining of large parts due to their large diameter boring bars and good rigidity, making them suitable for heavy-duty cutting tasks.

Additionally, some CNC machines integrate laser processing technology, enabling them to perform operations such as cutting, welding, marking, and surface treatment, thus expanding the application range of CNC machines. CNC punch presses focus on punching and forming of metal sheets, while CNC electric discharge machines use the principle of electric discharge, making them especially suitable for machining hard materials or parts with complex shapes.

The drive systems of CNC machines also exhibit a rich diversity. So, where is this diversity specifically reflected?

(1) Driving Method:

Open-loop systems, due to the absence of feedback devices, mainly rely on stepper motors as the actuating elements. They are simple in structure and low in cost, making them very suitable for applications where the processing accuracy requirement is not high. Closed-loop systems, on the other hand, integrate feedback devices with servo motors as the actuating elements to provide higher machining accuracy and stability, meeting the needs of precision machining.

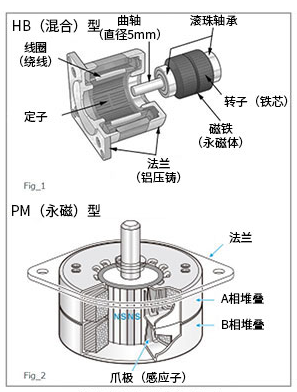

(2) Motor Types:

Stepper motors are widely used in economical CNC machines due to their low cost and simple control, despite their limitations in high-speed movement and smoothness. Compared to them, DC servo motors can offer superior speed control and torque output, but their relatively high maintenance costs limit their application range. With technological advancements, AC servo motors have become the preferred choice for modern CNC machines with their high efficiency, fast response, and lower maintenance costs.

(3) Control Units:

They can be basic pulse generators or more complex and advanced digital or analog servo drivers.The control units convert CNC feed commands into actuator signals for precise machine tool movement.

(4) Feedback Detection Systems:

We typically use feedback-free systems in situations where accuracy requirements are not high, owing to their low cost and simple structure. However, high-precision and high-performance applications require the support of feedback systems, such as encoders and scales, which can provide accurate position and speed feedback for finer control.

(5) Transmission Mechanisms:

Ball screws, as a common transmission method, are favored for their precise linear motion control. Gear rack systems are more suitable for applications that require long travel and can withstand greater loads. We commonly use belt drives in applications with relatively light loads due to their high cost-effectiveness.

The accuracy grades of CNC machines are typically categorized according to national standards, which stipulate the precision requirements of the machines to ensure that parts manufactured meet the required specifications. The categorization of accuracy grades is primarily based on indicators such as the machine’s positioning accuracy, repeatability, machining accuracy, and surface finish.

Next, let’s continue browsing to see how the accuracy grades are divided.

We typically categorize the precision grades of CNC machine tools according to national standards.

In China, this is outlined in the national standard GB/T 25372-2010 “Metal Cutting Machine Tools – Accuracy Grade”. This standard establishes the principles for classifying the accuracy of machine tools. We divide machine tools into six absolute accuracy grades, using Roman numerals VI, V, IV, III, II, and I, where grade VI is the lowest and grade I is the highest in precision.

Furthermore, we divide each type of machine tool into three relative accuracy grades, using the Chinese phonetic letters P, M, and G, based on these absolute accuracy grades.复制再试一次分享

The categorization of precision grades is primarily based on indicators such as the machine tool’s positioning accuracy, repeatability, machining accuracy, and surface roughness. These standards ensure that the machined parts meet the required specifications.

CNC machine tools’ processing accuracy is often related to tolerance grades, which range from IT01 to IT18, with a total of 20 grades. IT01 represents the highest machining accuracy, and IT18 represents the lowest. The smaller the tolerance grade, the higher the machining precision, and vice versa. For example, we generally consider grades IT7 and IT8 to represent medium levels of machining accuracy.