From the moment we learned to extract metal from the earth, our civilization began racing forward at an accelerated pace. Back then, blacksmiths worked tirelessly by the fireside, forging cold, hard materials into tools and weapons. They likely never imagined that these early techniques would one day form the foundation of modern manufacturing. When the Industrial Revolution hit, metalworking gained unprecedented speed and precision, sparking endless innovations and raising our manufacturing capabilities to new heights. Today, metal cutting technology permeates every corner of our lives—from cars and planes to buildings and electronics. Behind every modern achievement, you’ll find the essential presence of cutting tools. Let’s dive into the world of these indispensable metal cutting tools and see how they shape our world and open new possibilities for the future.

Metal cutting tools form the backbone of modern manufacturing, each with unique roles and advantages. From versatile milling cutters, circular saw blades, and carbide turning tools to high-speed plasma and laser cutters, to waterjets that offer cool cutting, durable diamond wheels, flexible bandsaws, surface-cleaning wire brushes, and handy grinders for smaller tasks—these ten metal cutting tools cover a wide range, from rough to fine machining needs. This article not only explores each tool’s features and best-use scenarios but also provides practical tips for choosing the right tools based on the task and material. Whether you’re handling large-scale production or customized work, these tools help you achieve more efficient and precise results.

Today, we’ll take a closer look at the ten most popular metal cutting tools, exploring their specific advantages and how they excel in different applications!

The Ten Best Metal Cutting Tools

Milling Cutter

The milling cutter is a versatile powerhouse in any workshop. It works well for cutting, planing, contouring, and grooving, handling everything from rough cuts to fine finishing. With the right material and coating, it tackles various metals, especially steel and stainless steel, with ease.

Circular Saw Blade

Circular saw blades deliver fast, clean cuts, making them ideal for metal sheets and pipes. Different tooth designs allow them to perform excellently on various thicknesses and materials, making them a popular choice for industrial cutting tasks.

Tungsten Carbide Turning Tool

Designed specifically for hard metals, tungsten carbide turning tools excel in turning tasks. With high wear resistance, they stay sharp even at high speeds, proving reliable in production settings.

Plasma Cutter

Using a high-temperature plasma arc, plasma cutters quickly melt through metal, offering fast and precise cuts. They’re especially suited for thick metal sheets and are ideal for processing steel and aluminum.

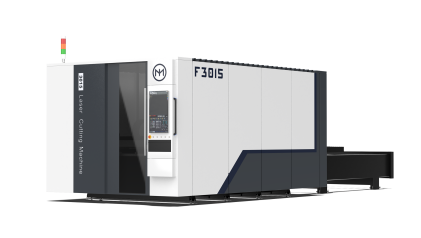

Laser Cutter

Known for its incredible precision, the laser cutter handles both thin metals and thick plates with ease. Its high speed and detailed cutting make it perfect for projects requiring tight tolerances and complex shapes.

Waterjet Cutter

The waterjet cutter uses high-pressure water with abrasives to cut through metal, making it suitable for materials that can’t withstand heat, like aluminum and stainless steel. Its cold-cutting feature makes it an ideal tool for processing heat-sensitive materials.

Diamond Grinding Wheel

With extreme hardness and durability, diamond grinding wheels are essential for heavy-duty tasks. They are especially effective on tough materials like titanium and carbide.

Bandsaw

A flexible tool, the bandsaw handles irregular shapes and complex curves with ease. It performs well on steel and other heavy materials, making it a staple in industrial and workshop environments.

Wire Brush Tool

Wire brush tools are ideal for surface removal and cleaning tasks. They quickly clear away welding slag, rust, and oxidation, making metal surfaces ready for further processing.

Handheld Grinder

A versatile tool for small tasks, the handheld grinder handles cutting, polishing, and grinding. It’s popular in small-scale machining, DIY projects, and repair work.

Frequently Asked Questions

How do you choose the right cutting tool based on metal type?

When selecting a cutting tool, start by considering the metal’s hardness and toughness. For harder materials like stainless steel and titanium alloys, tungsten carbide tools, diamond grinding wheels, and laser cutters are ideal. For softer metals such as aluminum and copper, high-speed steel tools, bandsaws, or waterjet cutters work well. By matching tool material with metal properties, you ensure the best cutting results and extend tool life.

How does tool maintenance differ between various cutting tools?

Different tools have specific maintenance needs. Mechanical tools like milling cutters and bandsaws need regular blade sharpness checks, residue cleaning, and proper lubrication. High-tech tools, such as laser and plasma cutters, require consistent light source stability and gas supply, along with regular calibration. Waterjet cutters need abrasive replacement and routine system cleaning. With proper maintenance, you can extend tool life and maintain cutting quality.

Should you consider tool coatings and materials when choosing a cutting tool?

Yes, tool coatings and materials significantly impact cutting performance and durability. Common coatings, like Titanium Nitride (TiN) and Titanium Aluminum Nitride (TiAlN), improve wear resistance and oxidation resistance, making them suitable for high-speed cutting and hard metals. In terms of tool material, high-speed steel works best for softer metals, while tungsten carbide and ceramic tools are excellent for harder metals. Choosing the right coating and material for the cutting conditions can boost production efficiency and reduce tool replacement frequency.

How do you choose the right tool based on the precision required for the cutting task?

Tasks requiring high precision often need stable, controllable tools. For detailed edges and complex contours, laser and waterjet cutters work well. For tasks with standard precision needs, handheld grinders or bandsaws offer quick, efficient results. Understanding the precision requirements of the task helps determine the right tool type to achieve the desired outcome.

Conclusion: Find the Right Metal Cutting Tool for You

When selecting a cutting tool, it’s essential to understand each tool’s features and application scenarios. Whether you need the high efficiency of a plasma cutter or the versatility of a handheld grinder for smaller tasks, each tool shines in specific situations. After reading this, I hope you’ll be better equipped to choose the right tool, enhance your machining efficiency, and have a professional guide for your next project.