In today’s pursuit of personalized design and efficient production, the 3-axis CNC router has become a “secret weapon” across various industries. From woodworking and metalworking to model making and sign design, this machine is everywhere. Whether for intricate pattern carving or precise cutting and shaping, a 3-axis CNC router handles it all effortlessly. With its high precision and fast batch production, it helps businesses turn complex designs into high-quality products. For industry professionals who value quality and efficiency, this equipment is a key tool for achieving both creativity and productivity.

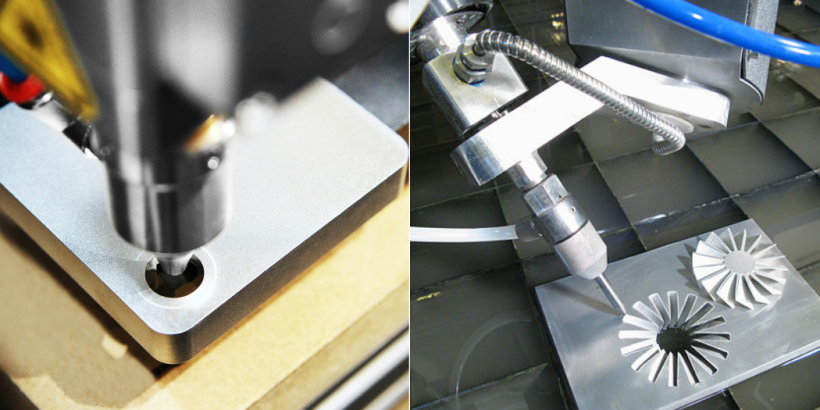

The 3-axis CNC router is a versatile machine mainly used for precise cutting, engraving, and shaping on various materials. With movement along the X, Y, and Z axes, it’s ideal for processing wood, plastic, foam, and some soft metals, making it widely used in furniture production, model making, and signage.

This article will cover four main aspects to help you understand the powerful features and wide uses of 3-axis CNC routers: equipment principles, application scenarios, buying tips, and cost analysis.

Working Principle of the 3-Axis CNC Router

The structure and working principle of the 3-axis CNC router are relatively simple, yet it is highly powerful. Through precise control of its three axes—X for left-right movement, Y for forward-backward movement, and Z for up-down movement—the machine converts design patterns from CNC programs into actual engravings. Unlike manual operation, the CNC router uses a computer control system to accurately position the tool, ensuring consistent precision in the size and shape of each cut. This automated control allows the router to excel in both batch production and complex designs.

Main Application Areas

- Furniture Making: The 3-axis CNC router is widely used in carving and shaping furniture components, such as chair backs, tabletops, and cabinet panels. It’s especially suited for intricate patterns and detailed engravings.

- Wooden Decorations: The router easily creates fine patterns and designs on wood, making it perfect for producing wooden decorations, pendants, and crafts.

- Signage and Advertising Production

- Sign Making: The CNC router can accurately cut and engrave various shapes and sizes on materials like plastic and acrylic, creating high-quality signs.

- Advertising Design: Ideal for producing multi-layered, textured signs, such as company logos, outdoor signs, and 3D letters. It provides smooth cutting edges and a uniform appearance.

- Model and Prototype Making

- Architectural Models: In architectural model making, the 3-axis router is used to cut lightweight materials like foam and plastic, quickly shaping building structures and details.

- Industrial Prototypes: The machine is ideal for creating product prototypes, especially those requiring complex shapes or fine textures, helping businesses with design validation and display.

- Light Metal Processing

- Soft Metal Parts: With appropriate settings, the 3-axis CNC router can cut softer metals like aluminum and brass. It’s suitable for making signs, engraved badges, and metal ornaments.

Equipment Performance and Specifications

What is the maximum machining size of a 3-axis CNC router? Can it handle large workpieces?

The machining size of a 3-axis CNC router varies based on model and brand. Small machines are suitable for tabletop crafts, while larger models can process bigger workpieces. Typical sizes range from 600×400 mm to 2000×3000 mm, with some industrial models supporting even larger dimensions. For applications like furniture, large signs, and billboards, a large 3-axis router can fully meet the requirements. When choosing, it’s essential to match the table size with your production needs to ensure efficient handling of large workpieces.

What are the spindle power and maximum speed? Which materials are suitable?

The spindle power of a 3-axis CNC router typically ranges from 1.5 kW to 7.5 kW, depending on the material’s hardness and thickness. The maximum spindle speed usually falls between 18,000 to 24,000 RPM. Higher speeds are better for carving fine details and intricate designs. Lower-powered spindles work well for soft materials like wood, plastic, and foam, while higher-powered spindles can cut softer metals like aluminum and brass, as well as some composite materials. Choosing the right spindle power for your materials is essential for optimal efficiency and extended tool life.

How accurate is the cutting precision, and what is the tolerance range?

High-quality 3-axis CNC routers offer excellent cutting precision, with a tolerance range usually between ±0.01 mm to ±0.1 mm. This level of precision ensures consistency in engraving and cutting, which is crucial for parts with strict size and detail requirements. For producing furniture decorations, complex models, or intricate signs, precision is especially important. Selecting a router with high cutting accuracy can help maintain quality and meet tight tolerance needs.

Can the machining speed be adjusted? What are the recommended speeds for different materials?

The machining speed on a 3-axis CNC router is adjustable to suit the properties and requirements of different materials. Generally, soft materials like wood and plastic can be processed at higher speeds, while hard materials like metal and composites require slower speeds to avoid overheating or tool wear. For example, the recommended speed for wood is around 15-30 m/min, while for aluminum, it’s about 8-12 m/min. Setting the right speed not only boosts production efficiency but also ensures cutting quality.

What is the maximum cutting depth? Can it perform multi-layer cutting?

The maximum cutting depth of a 3-axis CNC router depends on spindle power and tool length, typically ranging from 50 mm to 150 mm. Multi-layer cutting is possible and very useful for carving complex patterns and processing thicker materials. By cutting layer by layer, the machine reduces the load on each pass, minimizes tool wear, and ensures even cutting results.

Does it support switching between different engraving tools on the same workpiece?

Most 3-axis CNC routers support multi-tool switching, especially those equipped with an automatic tool changer (ATC) system. For complex workpieces, you can switch tools based on design needs, using a rough tool for initial cutting and a finer tool for polishing. An automatic tool changer not only saves manual operation time but also enhances precision, making it suitable for efficiently completing complex tasks. This feature is especially valuable for engraving detailed patterns and multi-layered workpieces.

Material Compatibility

What materials can the 3-axis CNC router process? Is it suitable for hard materials?

The 3-axis CNC router supports a wide range of materials, including wood, plastic, foam, acrylic, and even some metals and composite materials. It performs especially well when cutting and engraving wood, acrylic, and plastic, achieving precise cuts and complex designs. However, its ability to process very hard materials is somewhat limited, especially for high-hardness metals like steel and titanium. For medium-hardness materials such as aluminum and brass, it can deliver good results if you use the right cutting speed and tool choice. Generally, selecting suitable materials helps maintain processing quality and reduces tool wear.

Can it engrave on softer metals like aluminum and brass?

Yes, the 3-axis CNC router can engrave on softer metals like aluminum and brass. By choosing the right tool and setting appropriate machining parameters, you can achieve clean cuts and surface engravings on these metals. Since aluminum and brass are relatively soft, they do not cause excessive wear on the router’s tools and spindle. Using lower feed rates and spindle speeds ensures smooth finishes and minimizes overheating. Additionally, using cooling measures, such as mist cooling, can further improve the machining results.

Will foam and plastic melt during machining with this device?

When machining foam and plastic, the 3-axis CNC router generally does not cause melting, but speed and spindle RPM settings are important. Foam and certain plastics, like PVC and polyethylene, are sensitive to heat, and high speeds may cause frictional heating, leading to warping or melting. For these materials, using a low spindle speed and a high feed rate helps reduce frictional heat. Additionally, sharp-edged tools can minimize heat buildup, ensuring a smoother process and cleaner cutting edges.

Can the router process composite materials like carbon fiber or fiberglass?

The 3-axis CNC router can also process composite materials, such as carbon fiber and fiberglass, but extra care is necessary due to their characteristics. Carbon fiber and fiberglass are hard and abrasive, which can cause significant tool wear, so using special wear-resistant tools is essential. Carbon fiber cutting usually requires high speed and a high-power spindle, along with suitable cooling to reduce dust. To protect the operator and the environment, adding dust extraction equipment or using an enclosed machining setup helps remove the fine dust particles produced during processing.

Are there special tool choices for wood or other specific materials?

Yes, there are various specialized tools available to enhance the CNC router’s performance for specific materials. For example:

- Wood-specific tools: Wood-cutting tools usually have single or double flutes, making them ideal for high-speed cutting, reducing burrs, and providing a smooth finish.

- Acrylic-specific tools: These tools are designed with a very sharp edge to prevent cracking or breaking during the cutting of acrylic and similar plastics.

- Metal engraving tools: Tools for soft metals like aluminum and brass are typically made from carbide for high wear resistance, allowing them to handle the greater cutting force of metal processing.

- Composite material tools: For carbon fiber and fiberglass, diamond-coated tools with high wear resistance are recommended, offering extended life and better surface quality.

Operation and Programming

Using a 3-axis CNC router for machining requires not only the machine’s performance but also some programming knowledge and operational skills. Here are common questions and detailed answers on operation and programming to help users understand the machine’s requirements and its compatibility with design software.

Is it compatible with common design software, such as AutoCAD, SolidWorks, or Rhino?

Yes, the 3-axis CNC router is typically compatible with popular CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software like AutoCAD, SolidWorks, and Rhino. These programs allow users to design machining patterns and create CNC toolpaths. After completing the design, users can export files in router-supported formats like DXF or STL, then optimize the toolpath and machining settings through the router’s control software. This compatibility with mainstream software not only improves work efficiency but also allows users to handle complex designs more flexibly, importing them directly into the machine for processing.

Does the machine support G-code programming? Can it import DXF or STL format files?

Most 3-axis CNC routers support G-code programming, which is the standard language for CNC machining. G-code directly controls the router’s cutting path, speed, spindle rotation, and feed rate, making it ideal for projects requiring precise control. In addition to G-code, the 3-axis router supports common file formats like DXF and STL. DXF files are suited for 2D cutting paths, while STL files are widely used for 3D models. This file compatibility allows users to import design files directly into the machine, reducing the time needed for manual programming and boosting machining efficiency.

Is there an automatic tool-setting function? How difficult is manual tool-setting?

Some high-end 3-axis CNC routers come with an automatic tool-setting function, which quickly and accurately positions the tool relative to the workpiece. This feature greatly enhances machining precision and reduces manual setup time. For models without an automatic tool-setting function, manual tool-setting is usually required. The difficulty of manual tool-setting depends on the user’s experience and familiarity with the tool. Generally, manual tool-setting involves using a tool-setting block or probe to adjust the tool’s position, ensuring the starting point and cutting depth are accurate. Although manual tool-setting requires some skill, most operators can learn it easily after basic training.

Cost and Return on Investment

What is the price range for a 3-axis CNC router? What configuration options are available?

The price of a 3-axis CNC router varies based on brand, model, spindle power, machining size, and level of automation. Entry-level desktop routers typically cost between $700 and $3,000, suitable for small-scale production and light-duty work. Mid-sized industrial routers are priced around $4,000 to $15,000, making them ideal for medium-scale manufacturers, with higher power and larger machining sizes. High-end, large models may exceed $15,000, offering greater spindle power and advanced control systems for high-volume production and precision machining. Additionally, high-end models may offer options like automatic tool changers, cooling systems, and dust covers. While these add-ons increase the initial investment, they enhance productivity and machine durability.

Are the operating costs high? What are the main consumables?

Operating costs for a 3-axis CNC router are moderate, mainly including consumables, maintenance, and electricity. Key consumables include engraving tools and coolant. Tool wear depends on material hardness and the volume of work, typically requiring tool replacement several times a month. Tool prices range from $10 to $80, with specialized or high-durability tools costing more. For metalworking, coolant is essential to prevent overheating and improve cutting quality. Overall, daily consumable costs are manageable, and regular maintenance helps extend machine life.

What are the hidden costs beyond the purchase price?

Beyond the initial purchase, hidden costs of a 3-axis CNC router include:

- Maintenance Costs: Regular lubrication, cleaning, and part replacements are essential for precision and longevity.

- Tool Wear: Tool wear increases, especially when machining harder materials.

- Coolant Use and Disposal: Coolant is a long-term expense, especially for metalworking.

- Training Costs: Operators, especially for high-end machines, may require training to operate effectively.

- Repair Costs: Choosing a brand with reliable after-sales service can help minimize long-term repair expenses.

Is the power consumption high? What are the power requirements?

Power consumption in a 3-axis CNC router mainly comes from the spindle, servo motors, and control system. Small to mid-sized routers consume around 2 to 5 kilowatts, while larger, high-power models may exceed 7 kilowatts. Although power use isn’t low, the productivity boost often justifies the electricity cost. Running the machine at an optimal feed rate and spindle speed can reduce unnecessary power use. Ensure the workspace has adequate electrical capacity before installation. For industrial-grade equipment, a three-phase power supply is recommended for stable operation.

Conclusion: Choose Minnuo Group’s 3-Axis CNC Router for Efficient and Precise Machining

With its high efficiency and precision, the 3-axis CNC router excels in industries like furniture, advertising, and model making. Minnuo Group’s equipment stands out among the best, offering a variety of configurations to meet diverse production needs, from small batches to large-scale manufacturing. Our routers deliver exceptional spindle power, cutting accuracy, and automatic tool-changing features, along with reliable after-sales support, making high-quality machining effortless.