In today’s highly competitive manufacturing industry, the choice of machine tools directly impacts production efficiency, machining accuracy, and the final product quality. However, many companies feel confused when faced with numerous options, especially when choosing between slant bed lathes and traditional flat bed lathes. As technology continues to evolve, the slant bed lathe, with its innovative design and excellent performance, is becoming the preferred solution for more and more companies. It can significantly improve processing efficiency and enhance machining accuracy. However, the higher initial investment also makes some companies hesitant. Is the slant bed lathe worth the investment? What kind of practical benefits can it bring to businesses? These are the key questions decision-makers are focusing on.

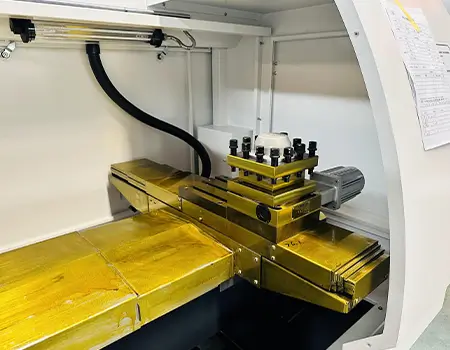

Compared to traditional flat bed lathes, the slant bed lathe optimizes the transmission of cutting forces with its inclined bed design, reducing vibrations and improving both machining accuracy and stability. It excels in high-load, high-precision tasks and is especially suitable for mass production and processing of high-hardness materials. Although the initial investment is higher, the slant bed lathe can recover this cost in a short period by increasing production efficiency, reducing maintenance frequency, and extending tool life, offering long-term benefits.

Next, we will explore how the slant bed lathe can improve production efficiency, reduce machining errors, and help extend the machine’s service life through proper maintenance.

Key Differences Between Slant Bed Lathes and Flat Bed Lathes: Why Choosing a Slant Bed Lathe Leads to Higher Efficiency

The main difference between flat bed lathes and slant bed lathes lies in the design of their beds. The flat bed lathe has a horizontal design, while the slant bed lathe has an inclined bed. This difference directly impacts machining efficiency, accuracy, and future maintenance challenges.

Cutting Force Transmission and Stability

The bed of a slant bed lathe is typically inclined at an angle of 30° to 45°. This design helps optimize the transmission of cutting forces, reduces vibrations, and makes the machining process more stable. For high-precision tasks, such as precision molds or machining of high-hardness materials, the slant bed lathe can significantly reduce the impact of vibrations on accuracy, ensuring stable machining. On the other hand, flat bed lathes have uneven cutting force distribution due to their horizontal bed design. This leads to more vibrations, which can affect machining accuracy, especially under heavy loads.

Chip Removal Efficiency

During machining, chips can be a major factor affecting production efficiency. The inclined design of the slant bed lathe ensures smoother chip removal, preventing chips from accumulating and impacting both machining accuracy and machine life. In contrast, the horizontal structure of the flat bed lathe makes it easier for chips to build up, increasing downtime and maintenance costs during machining.

How to Improve Production Efficiency with a Slant Bed Lathes: Key Factors and Practical Operations

When choosing a slant bed lathe, improving production efficiency is a key concern for many businesses. How can companies optimize operations to maximize the efficiency of a slant bed lathe in actual production? The following factors are crucial:

Shorter Production Cycle

Compared to traditional flat bed lathes, the design of the slant bed lathe makes the cutting process more stable, reduces vibration, and extends tool life. This allows for stable machining quality at higher cutting speeds, which directly shortens the production cycle. In mass production, this means more parts can be processed in a given time, boosting overall production efficiency.

Ability to Handle Higher Cutting Speeds and Loads

The slant bed lathe has much better stability during high-load machining than a flat bed lathe. This allows it to perform tasks at higher cutting speeds. This feature is especially useful in high-productivity mass production. For companies, being able to increase cutting speed without sacrificing machining accuracy means shorter production cycles and lower production costs.

Reduced Maintenance Time and Man-Hours

With smoother chip removal and less vibration, the Slant-Type Lathe requires simpler daily maintenance and inspections. This reduces machine failures and downtime caused by chip buildup. In practice, stable operation helps businesses save significant maintenance time, further improving production efficiency.

Machining Precision of Slant Bed Lathes: How to Ensure High Precision Tasks Are Not Affected

For many high-precision machining tasks, such as mold manufacturing or aerospace parts production, a slant bed lathe must not only provide efficient machining but also ensure machining accuracy. How can companies ensure that the slant bed lathe delivers the required precision during actual operations? This is a key concern for many businesses.

Reducing Vibration to Improve Precision

The slant bed lathe effectively reduces vibration during the machining process, ensuring good contact between the tool and the workpiece. This results in more even distribution of cutting forces. For high-precision parts, this is critical. Reducing vibration not only improves machining accuracy but also extends tool life and lowers overall maintenance costs.

Optimizing Cutting Parameters

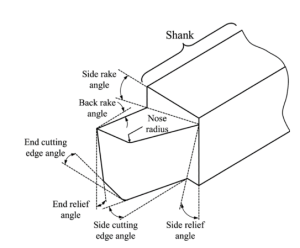

When performing high-precision machining on a slant bed lathe, selecting the right cutting speed, feed rate, and tool materials is key to ensuring precision. By setting these parameters correctly, businesses can avoid errors caused by excessive or uneven cutting, ensuring that the results meet micron-level accuracy requirements.

Stability for Machining Hard Materials

Slant bed lathes offer better stability when machining hard materials. Hard materials usually require higher cutting forces and smaller cutting edge angles. The design of the slant bed lathe enhances the cutting efficiency of tools and maintains stable machining over extended periods, preventing excessive errors during the machining process.

Cost and Return on Investment of Slant Bed Lathes: Is the High Investment Worth It?

Many small businesses or medium-sized workshops often worry about the high initial investment when considering the purchase of a slant bed lathe. To determine whether the investment in a slant bed lathe is reasonable, it is crucial to understand its long-term benefits.

Initial Investment and Payback Period

The price of a Slant-Type Latheis generally higher than that of a flat bed lathe, especially for high-precision and high-performance requirements. However, in most cases, this investment is worthwhile. By improving machining efficiency, reducing labor hours, and extending tool life, a slant bed lathe can help businesses recover their investment in a short period, typically within 1 to 3 years.

Improvement in Production Efficiency

In terms of production efficiency, slant bed lathes can significantly reduce production cycles and increase the number of parts processed per hour. In long-term batch production, the high efficiency of slant bed lathes often makes up for the initial high investment within one year, generating greater output value.

Lower Long-Term Costs

The advantages of slant bed lathes in reducing cutting vibrations, optimizing chip removal, and improving machining accuracy directly reduce maintenance costs and tool replacement frequency. Businesses can greatly reduce maintenance hours and tool replacement costs when using a Slant-Type Lathe, thus increasing profits per unit product.

Maintenance and Lifespan of Slant Bed Lathes: Practical Strategies for Extending Machine Life

Although slant bed lathes have a long lifespan, proper maintenance plays a critical role in extending their service life during actual operation.

Regular Maintenance and Care

Slant bed lathes require regular checks on the lubrication system, cutting fluids, and bed components to ensure that these key parts are in good condition. Regular cleaning of the bed and checking of the oil and fluids help prevent chip buildup on critical components, effectively avoiding failures due to wear.

Professional Operation

The structure of a Slant-Type Lathe requires certain technical expertise to operate. Businesses should ensure that operators receive professional training. They should understand how to extend the machine’s lifespan by optimizing operational parameters such as cutting speed and feed rate.

Predictive Maintenance

Using intelligent systems and sensors for predictive maintenance allows for earlier detection of potential issues. Problems can be fixed before they become serious, greatly reducing downtime caused by unexpected failures and maintaining production continuity.

Conclusion

Slant bed lathes demonstrate clear advantages in improving production efficiency, ensuring machining precision, and extending machine life, especially for high-load and high-precision tasks. Although the initial investment is higher, the long-term benefits—whether in shortening production cycles, reducing maintenance costs, or increasing productivity—make up for this gap. As a leading brand in the industry, Minnuo’s slant bed lathes, with their advanced technology and reliable performance, have become the first choice for many businesses. Choosing Minnuo means choosing not just an efficient machine but also lasting quality assurance and comprehensive technical support, helping your production reach new heights. Visit our official website to learn more about our products and services. We look forward to working with you to drive productivity improvements!