In today’s machining industry, companies face the dual challenge of improving production efficiency while ensuring processing quality and precision. As market demands evolve and manufacturing costs increase, businesses must respond quickly to customer needs while maintaining product consistency. This raises higher requirements for optimizing production processes. At the same time, intensifying global competition makes process optimization a critical factor for enhancing business competitiveness. The industry is shifting toward precision machining and efficient production, with stricter demands on refining process parameters, especially in selecting and adjusting cutting speed and feed rate.

Determining the best machining parameters under complex conditions has become a pressing issue for every manufacturer. Feed rate and cutting speed are the most critical process parameters in machining. They directly impact machining results, tool life, and production costs. Proper cutting speed and feed rate can boost productivity, improve machining quality, and extend tool lifespan. However, improper settings can lead to substandard precision, increased energy consumption, tool wear, or even equipment failure, which results in unnecessary costs.

This article explains the definitions, differences, and relationships between feed rate and cutting speed. It also provides calculation methods to help you optimize machining parameters based on your specific needs.

Basic Concepts of Feed Rate and Cutting Speed

What is Feed Rate?

Feed rate refers to the linear speed at which a cutting tool moves relative to the workpiece during machining. It is usually expressed in millimeters per minute (mm/min) or millimeters per revolution (mm/rev). Feed rate reflects the relative movement speed between the tool and the workpiece within a unit of time. It directly affects the cutting force, chip formation, and surface quality of the workpiece. A higher feed rate increases the cutting volume per unit of time, which improves machining efficiency. However, excessively high feed rates may lead to increased surface roughness or machining vibrations. Adjusting the feed rate properly helps strike a balance between machining efficiency and surface quality.

What is Cutting Speed?

Cutting speed refers to the instantaneous speed at the point of contact between the cutting tool and the workpiece. It is usually measured in meters per minute (m/min). Cutting speed is one of the key parameters that influence cutting temperature, cutting force, and tool wear. Higher cutting speeds enhance machining efficiency but also generate more heat and accelerate tool wear, which may significantly reduce tool life. Optimizing the cutting speed can help control heat buildup, extend tool life, and improve machining quality.

The Role of Both in Machining

Feed rate and cutting speed work closely together in machining, complementing each other. Their balance directly impacts machining quality and efficiency. Cutting speed mainly determines the temperature in the cutting zone and the speed of chip formation. Higher cutting speeds improve machining efficiency but may generate excessive heat, which accelerates tool wear and affects surface quality. On the other hand, feed rate directly affects cutting force, surface roughness, and tool load. A higher feed rate increases production efficiency but can lead to higher surface roughness or even vibrations, which may compromise machining precision. Balancing these two parameters is critical to achieving optimal results in machining.

In addition, matching cutting speed and feed rate is especially critical when machining different materials. For example, when machining hardened steel or titanium alloys, using an excessively high cutting speed may cause excessive heat buildup and accelerate tool wear. Meanwhile, a moderate feed rate helps reduce cutting force and improve surface quality. By precisely adjusting the combination of cutting speed and feed rate, it becomes easier to balance machining efficiency and quality. This adjustment enhances the stability and cost-effectiveness of the entire production process.

Feed rate and cutting speed are crucial in CNC machining.

Boosting Machining Efficiency

Feed rate and cutting speed directly determine machining time during the cutting process. Higher cutting speeds combined with appropriate feed rates reduce the time required for each workpiece, thus increasing production efficiency. For instance, during high-speed cutting, excessively low cutting speeds can lead to unnecessary machining time, while overly high feed rates may cause excessive tool wear. Balancing cutting speed and feed rate effectively maximizes production efficiency.

Improving Machining Quality

The choice of cutting speed and feed rate significantly affects surface roughness and workpiece accuracy. Higher cutting speeds often result in higher cutting temperatures, which can impact surface quality. Similarly, feed rates that are too low or too high may lead to excessive surface roughness or uneven machining. By optimizing these two parameters, CNC machining can achieve smoother surfaces with greater precision.

Extending Tool Life

Tool wear is a critical issue in CNC machining. Improper or excessive cutting speed and feed rate accelerate tool wear and shorten tool lifespan. This is particularly important when machining high-hardness materials. Proper cutting speeds and feed rates reduce tool load, extend tool life, minimize downtime, and enhance production stability.

The Relationship and Differences Between Feed Rate and Cutting Speed

Feed rate and cutting speed are two distinct process parameters, but they are closely interconnected in machining and work together to influence the final result.

The Relationship Between Feed Rate and Cutting Speed

Cutting speed and feed rate are core parameters that impact cutting force, cutting heat, and machining efficiency. Cutting speed determines the speed at which chips move per minute, while feed rate defines the distance the tool advances per revolution. Together, they affect the contact area between the tool and the workpiece, cutting force, and chip formation. In many cases, these parameters need adjustment based on material characteristics and machining requirements to maintain stability and efficiency. For example, during high-speed machining, higher cutting speeds combined with moderate feed rates accelerate the process while maintaining good surface quality.

The Differences Between Feed Rate and Cutting Speed

Cutting speed refers to the relative speed at the cutting interface between the tool and the workpiece. It is usually measured in meters per minute (m/min) or feet per minute (ft/min). Cutting speed directly affects the temperature in the cutting zone, chip formation speed, and thermal load on the tool. Higher cutting speeds lead to increased cutting temperatures and chip deformation, requiring better tool materials and cooling systems.

Feed rate refers to the distance the tool advances per revolution or per minute, typically measured in millimeters per revolution (mm/rev) or millimeters per minute (mm/min). Feed rate directly influences cutting force and surface roughness. Higher feed rates increase cutting force and may worsen surface roughness but improve machining efficiency. Lower feed rates enhance surface quality but reduce production efficiency.

Mutual Influence

High Cutting Speed with Low Feed Rate: This combination suits precision machining, providing better surface finish but sacrificing efficiency.

High Cutting Speed with High Feed Rate: This setup improves efficiency but requires attention to the tool’s thermal load and potential impact on surface quality.

Low Cutting Speed with High Feed Rate: This approach works well for hard materials, reducing tool wear but possibly affecting surface quality.

Calculation Methods for Feed Rate and Cutting Speed

Feed Rate Calculation Formula

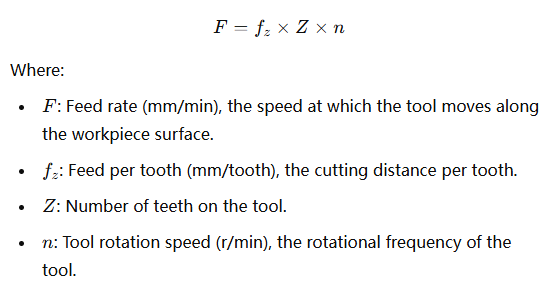

Feed rate refers to the distance the tool advances per revolution or per minute during machining. The calculation formula is:

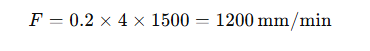

For example, if the tool’s feed per tooth is 0.2 mm, the tool rotation speed is 1500 rpm, and the tool has 4 teeth, the feed rate would be:

This formula helps engineers calculate the appropriate feed rate based on the tool’s parameters and machining requirements, ensuring optimal efficiency.

Cutting Speed Calculation Formula

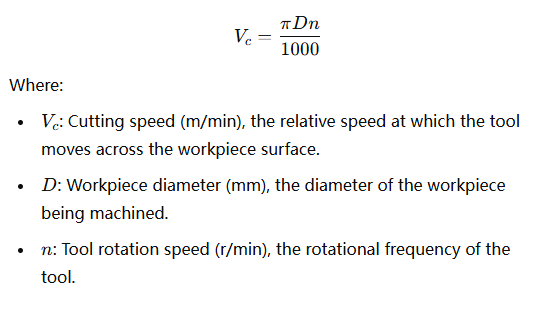

Cutting speed refers to the relative speed at the contact point between the tool and the workpiece. The formula is as follows:

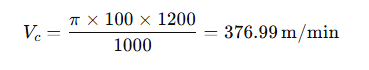

For instance, if the workpiece diameter is 100 mm and the tool rotation speed is 1200 rpm, the cutting speed would be:

Cutting speed directly impacts the temperature of the cutting area, the chip formation rate, and the wear rate of the tool. Selecting the appropriate cutting speed can effectively improve machining quality and extend tool life.

Application of Parameter Optimization Tools

CAD/CAM Software

Modern CAD/CAM software, such as Siemens NX, Mastercam, and SolidWorks, includes cutting parameter calculation modules. Engineers enter details like material, tool geometry, and equipment specifications. The software then generates suitable cutting parameters. It also offers simulation features for complex parts, helping engineers identify and resolve potential issues before actual machining.

Cutting Parameter Optimization Systems

Advanced manufacturing execution systems (MES) and production scheduling systems rely on real-time data collection and analysis. These systems dynamically adjust cutting parameters. For example, they monitor tool wear and cutting forces in real-time and automatically tweak feed rate and cutting speed. This improves efficiency while reducing tool wear.

Online Cutting Optimization Platforms

Online platforms, such as ToolBOSS and Sandvik Coromant’s CoroPlus, use big data and machine learning algorithms to optimize cutting parameters. Engineers can input material type, machining process, and machine capabilities. The platform quickly recommends the best cutting strategies. With cloud-based analysis, it continuously processes production data and provides optimal solutions.

Common Errors in Setting Feed Rate and Cutting Speed

Excessive Cutting Speed

Using a cutting speed that is too high causes the cutting zone temperature to rise sharply. This increases tool wear and deformation. When machining hard materials like titanium alloys or tool steel, excessive cutting speed can also result in surface burns, cracks, or annealing. Engineers should adjust the cutting speed based on the material’s thermal conductivity and the tool’s heat resistance.

Low Feed Rate

A low feed rate can improve accuracy and surface quality, but it often reduces machining efficiency and extends processing time. Additionally, a low feed rate may lead to chip accumulation, which increases tool wear and thermal load. In rough machining, increasing the feed rate boosts productivity and reduces tool load, improving overall performance.

Mismatch Between Feed Rate and Cutting Speed

Proper alignment between feed rate and cutting speed is crucial. High cutting speed combined with low feed rate shortens tool life and raises cutting zone temperatures. On the other hand, low cutting speed with high feed rate can degrade surface quality and cause vibrations. Engineers need to carefully balance these parameters by considering material properties, tool geometry, and machining requirements.

Ignoring Tool and Machine Limitations

Neglecting the limitations of tools and equipment can lead to serious problems. Engineers must account for the tool’s load capacity, material durability, and the machine’s maximum speed and power. Overlooking these factors can cause tool overload, machine vibrations, or equipment failures, ultimately reducing machining stability and quality.

How to Optimize Feed Rate and Cutting Speed to Improve Machining Performance

Adjust Cutting Parameters Based on Material Properties

The cutting characteristics of different materials greatly influence the selection of feed rate and cutting speed. For harder materials like titanium alloys or hardened steel, using lower cutting speeds and feed rates helps reduce tool wear and ensures high-precision machining. For softer materials like aluminum or copper alloys, higher cutting speeds and feed rates enhance production efficiency and save time.

Use Recommended Data from Tool Manufacturers

Tool manufacturers often provide recommended cutting speeds and feed rates for specific tools and materials. These recommendations are based on extensive experimental studies and can guide engineers in optimizing parameter settings. Referring to this data minimizes the risk of tool wear and machining defects caused by incorrect settings.

Leverage Advanced Cutting Optimization Tools

With technological advancements, modern CNC machines and CAD/CAM software come with integrated cutting optimization tools. These tools calculate the optimal cutting parameters by considering factors like material properties, tool specifications, and machine capabilities. Engineers can use simulations to anticipate potential problems during machining and make adjustments before actual production begins.

Monitor and Adjust Parameters in Real Time

In high-efficiency production environments, monitoring data like cutting force, temperature, and vibration in real-time helps engineers dynamically adjust feed rates and cutting speeds. By using force and temperature sensors, engineers can respond to tool wear and maintain optimal machining conditions throughout the process.

Choose Appropriate Tool Geometry and Coating

Tool geometry, such as rake angles, clearance angles, and cutting edge shapes, along with the choice of coating materials, significantly affects cutting performance. Selecting the right combination optimizes the cutting process, improves efficiency, and extends tool life. For example, when machining high-temperature alloys, tools with heat-resistant coatings and larger rake angles reduce cutting forces and minimize tool wear.

Common Issues and Solutions

Tools Wear Out Too Quickly: How to Adjust Cutting Speed?

- Lower Cutting Speed: Reducing cutting speed effectively lowers the temperature in the cutting zone. This helps slow down tool wear, especially when machining hard materials like hardened steel or titanium alloys. Excessive cutting speed in such cases often causes heat cracks and tool chipping, which accelerate wear.

- Improve Cooling and Lubrication: Increasing the flow of coolant or using high-performance lubricants can lower the cutting zone temperature and reduce thermal damage to the tool. Gas cooling or mist cooling systems are also effective for maintaining cooling performance during high-speed cutting.

- Optimize Feed Rate: Increasing the feed rate enhances chip evacuation, which reduces heat buildup in the cutting zone. Efficient chip removal decreases cutting forces and friction, helping to control temperature and reduce tool wear.

Surface Roughness Below Standard: Is the Feed Rate Too High?

Surface roughness issues often occur because of an excessively high feed rate. This creates uneven contact during cutting and leaves larger machining marks. To solve this, try the following:

- Reduce Feed Rate: A high feed rate increases the cutting amount per tooth, leading to deeper marks and higher surface roughness. Lowering the feed rate during finishing significantly improves surface smoothness and reduces machining errors.

- Optimize Cutting Speed and Tool Selection: Higher cutting speeds reduce chip retention time and minimize the depth of machining marks, which improves surface quality. Selecting the right tool material and geometry, such as rounded-edge tools or multi-flute cutters, also enhances surface finish.

- Check Tool Wear: Tool wear is another major cause of poor surface quality. A worn tool cannot maintain consistent cutting precision, leading to uneven cuts. Regularly inspect tool conditions and replace or recondition tools as needed to achieve better surface results.

Conclusion

Adjusting feed rate and cutting speed effectively improves machining efficiency, ensures quality, and extends tool life. By understanding the relationship between these parameters and tailoring them to specific needs, you can boost productivity while avoiding unnecessary losses and complications. Once you master these techniques, you’ll find that optimizing machining parameters is simpler than it seems. The key is finding the right balance, which helps you make precise, efficient decisions in your work.

If you have any questions about parameter optimization or improving machining performance, feel free to contact us at MINNUO. We are here to provide you with professional answers and help you achieve more efficient and reliable machining results!