CNC machining has revolutionized the manufacturing industry by using computers to control machine tools. It offers high precision and efficiency but also presents some challenges. This article examines the main pros and cons of CNC machining to help potential buyers and learners understand its impact on modern manufacturing.

CNC Machining: The Pros and Cons

CNC (Computer Numerical Control) machining offers high precision, consistency, and efficiency, making it ideal for producing complex parts in industries like aerospace, automotive, and medical devices. Its key advantages include the ability to operate 24/7, reduced labor costs, and the capability to create intricate geometries. However, CNC machining also has drawbacks, such as high initial costs, maintenance requirements, and the need for skilled programmers. Despite these challenges, the benefits of CNC machining often outweigh the disadvantages, providing significant value in modern manufacturing.

The Pros and Cons of CNC Machining – Dive into the world of precision with my latest article on the pros and cons of CNC machining!

What is CNC Machining?

CNC (Computer Numerical Control) machining is a technology where computers control machine tools to make precise parts. You design a part on a computer. This design is turned into instructions for the CNC machine. The machine then cuts, shapes, or drills the material based on these instructions.

Common CNC machines include:

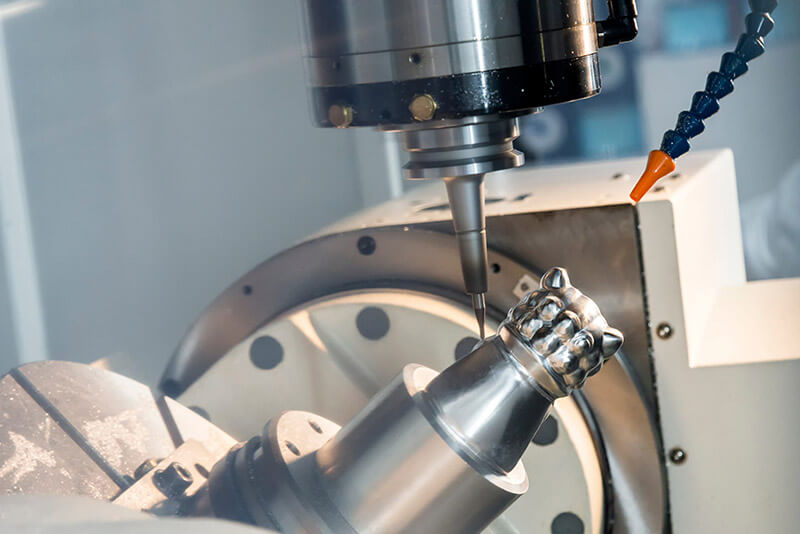

CNC Mills: Use rotating tools to cut material.

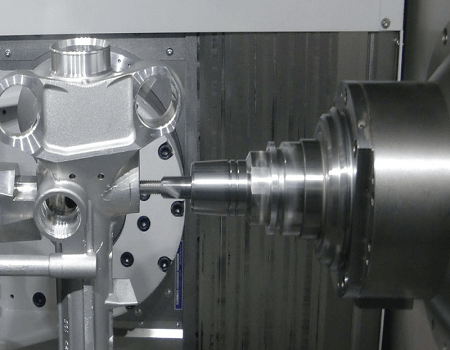

CNC Lathes: Rotate the material while a cutting tool shapes it.

CNC Routers: Similar to mills but often used for wood and plastic.

CNC machining automates the manufacturing process, making it faster and more accurate than manual methods.

Advantages of CNC Machining

Precision and Consistency

CNC machines produce parts with high precision and consistency. The computerized control ensures every part meets exact specifications, reducing errors and variations. For example, in the aerospace industry, where even minor deviations can cause significant issues, CNC machining ensures components meet stringent tolerance requirements.

Increased Production Efficiency

CNC machines operate continuously 24/7, significantly boosting production rates. They are not limited by human working hours and can produce large quantities of parts with minimal downtime. In automotive manufacturing, CNC machines can rapidly produce thousands of parts, meeting high demand efficiently.

Capability to Produce Complex Geometries

CNC machines can create intricate and complex shapes that would be challenging or impossible with manual machining. Multi-axis CNC machines can perform detailed machining in a single setup. Medical devices often require complex shapes and fine details, which CNC machining can achieve with high precision.

Reduced Labor Costs

Once programmed, CNC machines require minimal human intervention. This automation reduces the need for skilled labor and lowers labor costs, as operators can oversee multiple machines simultaneously. In a large manufacturing plant, one operator managing several CNC machines can lead to significant labor cost savings.

Flexibility and Versatility

CNC machines can be quickly reprogrammed to produce different parts, making them highly versatile. This flexibility allows manufacturers to adapt to changing demands and produce a wide range of products without significant downtime. A job shop can switch from producing one type of component to another with minimal setup time, meeting diverse customer needs efficiently.

Improved Safety

CNC machining reduces the risk of accidents and injuries since the operator does not need to be in close contact with the cutting tools. The automated nature of the process keeps human involvement to a minimum, enhancing workplace safety. In heavy industries where large and dangerous equipment is used, CNC machining provides a safer working environment by minimizing direct human interaction.

Scalability

CNC machining is highly scalable, making it ideal for both small and large-scale production. Once a program is set, the same design can be replicated countless times with precision. Electronics manufacturers can scale up production quickly to meet increasing demands without compromising on quality.

Faster Prototyping

CNC machining speeds up the prototyping process, allowing for rapid development and testing of new designs. This is crucial for businesses looking to innovate and bring new products to market quickly. A tech startup can prototype and refine its designs swiftly, reducing time to market and staying ahead of competitors.

Enhanced Material Utilization

CNC machines are programmed to optimize material usage, reducing waste and saving costs. This efficiency is particularly beneficial when working with expensive materials. In jewelry making, where materials like gold and platinum are costly, CNC machining minimizes material wastage, maximizing profitability.

Consistent Product Quality

With CNC machining, the first part produced will be identical to the thousandth part, ensuring consistent product quality. This consistency is vital for maintaining brand reputation and customer satisfaction. Consumer electronics brands rely on CNC machining to produce high-quality, identical components, ensuring their products meet customer expectations.

Integration with Modern Technologies

CNC machines can be integrated with other modern technologies, such as IoT and AI, to enhance efficiency and predictive maintenance. Smart factories utilize CNC machines connected to IoT networks to monitor performance in real-time and predict maintenance needs, reducing downtime and operational costs.

Why CNC Machining is Important

CNC machining is critical to modern manufacturing. It’s the backbone of production lines, ensuring high-quality output with minimal waste. CNC machining is important because it:

- Expands Production Capabilities: Manufacturers can produce complex parts that meet high-quality standards.

- Drives Innovation: You can create innovative products with intricate designs and precise specifications.

- Improves Competitiveness: You can reduce production costs and improve product quality to stay competitive.

CNC Machining Applications

CNC machining is used in many industries because it’s versatile and precise. Some applications include:

- Aerospace: You can produce high-precision components like turbine blades and engine parts.

- Automotive: You can manufacture engine components, transmission parts, and intricate body parts.

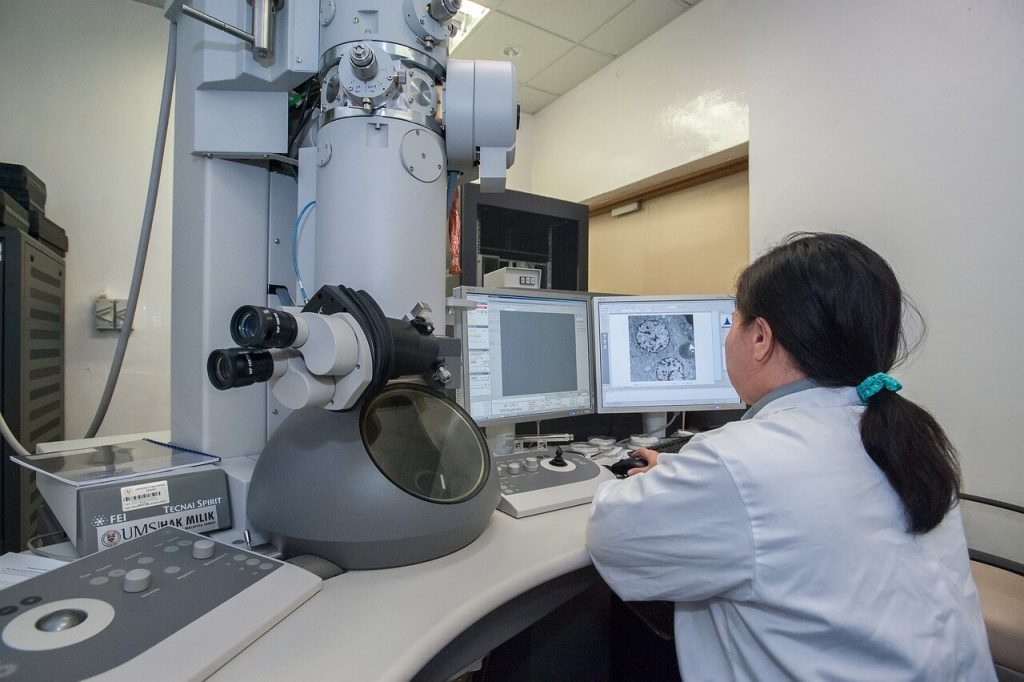

- Medical Devices: You can create complex surgical instruments, implants, and diagnostic equipment.

- Electronics: You can fabricate precise housings and components for consumer electronics.

- Industrial Equipment: You can produce robust parts for heavy machinery and equipment.

CNC Machining Disadvantages

While CNC machining has many benefits, there are some drawbacks:

High Initial Cost

CNC machines, especially those capable of multi-axis operations, are expensive. The initial investment can be a barrier for small businesses.

Maintenance and Downtime

CNC machines require regular maintenance to ensure accuracy and efficiency. This maintenance can be costly and time-consuming, potentially leading to production downtime.

Skilled Labor Requirement

Operating CNC machines requires skilled programmers who can write and debug the necessary code. Finding and retaining such talent can be challenging and costly.

Energy Consumption

CNC machines consume a lot of energy, especially when running continuously. This high energy consumption can lead to increased operational costs.

Complexity of Setup

Setting up a CNC machine for a new production run can be complex and time-consuming. This complexity can slow down the manufacturing process, especially for short production runs.

Limited to Certain Materials

While CNC machines can handle a wide range of materials, there are limitations. Some materials may be too hard, too soft, or otherwise unsuitable for CNC machining, requiring alternative methods.

CNC Machining Methods

There are several methods within CNC machining, each suited for different tasks:

CNC Milling

CNC milling involves rotating cutting tools to remove material from a workpiece. It’s ideal for creating complex shapes and profiles.

CNC Turning

CNC turning uses a lathe to rotate the workpiece while a stationary cutting tool shapes it. This method is excellent for producing cylindrical parts.

CNC Drilling

CNC drilling precisely drills holes into a workpiece using a rotating drill bit. It’s commonly used in manufacturing parts that require accurate hole placement.

CNC Grinding

CNC grinding uses an abrasive wheel to remove material, providing a high-precision finish. It’s often used for finishing hardened surfaces.

CNC Routing

CNC routing cuts complex shapes and patterns from materials like wood, plastic, and soft metals. It’s often used in cabinetry and sign-making.

How to Choose a Good CNC Machining Service

Here are some things to consider when choosing a CNC machining service:

- Define Your Requirements: clearly define your project’s specifications, including the type of material, the complexity of the part, and your precision requirements.

- Evaluate Capabilities: evaluate the capabilities of the CNC machining service, including their equipment, technology, and expertise. Make sure they can handle your project’s specific needs.

- Check Quality Assurance: look for a provider that has strong quality assurance processes, including certifications like ISO 9001. This ensures they have high standards.

- Consider Experience: choose a provider that has experience in your industry. They will be familiar with the specific requirements of your industry, which can be a huge help.

- Review Turnaround Time: make sure the provider can meet your timeline requirements. Quick turnaround times are important to keep your production schedule on track.

- Compare Costs: while cost shouldn’t be the only factor, it is important. Get quotes from multiple providers to make sure you’re getting good value for your money without sacrificing quality.

- Customer Support: consider the level of customer support that is offered. Responsive and helpful customer service can make a big difference in your overall experience.

How to Choose the Right CNC Machine

Choosing the right CNC machine for your needs involves several critical factors:

- Figure Out What You Need Determine what you need the machine to do. Consider the types of materials you’ll be working with, the complexity of the parts you’ll be producing, and the precision required.

- See What the Machine Can Do Look at the machine’s capabilities, including its size, power, speed, and accuracy. Make sure it can handle the maximum size and weight of the workpieces you plan to machine.

- Make Sure the Software Works Make sure the CNC machine is compatible with your existing CAD/CAM software or any other software you plan to use. This will streamline the design-to-production process.

- Make Sure the Machine Is Flexible Choose a machine that offers the flexibility to handle various tasks and can be easily reprogrammed for different projects.

- Check the Build Quality and Durability Invest in a machine that is built to last, with high-quality components and a robust construction. This will ensure reliable performance and longevity.

- Check the Maintenance and Support Services Consider the availability of maintenance and support services from the manufacturer or supplier. Reliable after-sales support is crucial for keeping your machine running smoothly.

- Think About Your Budget Balance your needs with your budget. While it’s important to get a machine that meets your requirements, make sure it’s also a sound financial investment.

- Read Reviews and Get Recommendations Look for reviews and testimonials from other users in your industry. Getting recommendations from trusted sources can help you make a more informed decision.

Conclusion

CNC machining is a cornerstone of modern manufacturing, offering unmatched precision, efficiency, and versatility. While it has its challenges, the advantages often outweigh the drawbacks, especially for businesses aiming for high-quality production. By understanding the pros and cons, methods, and how to choose the right service and machine, you can leverage CNC machining to enhance your manufacturing processes.

FAQs on CNC Machining

What are the advantages of CNC machines over NC?

CNC machines offer greater automation, precision, and flexibility compared to NC machines. They can handle complex designs, provide consistent quality, and improve production efficiency with less manual intervention.

What are some of the advantages of CNC vs conventional machining?

CNC machining provides higher accuracy, consistency, and efficiency. It can produce complex geometries, reduces waste, and enhances safety by minimizing manual labor.

Should I buy CNC machining services or CNC machines?

Choose CNC machining services if you have limited budget and expertise, or need flexibility. Buy CNC machines if you have high production volumes and can invest in equipment and skilled operators.