Milling is a cornerstone of modern manufacturing, used to create precise parts from a wide range of materials. The process involves removing material from a workpiece using rotating cutting tools, a technique that has evolved significantly since its inception. The two main methods—climb milling and conventional milling—each have their own unique characteristics that make them suitable for different applications.

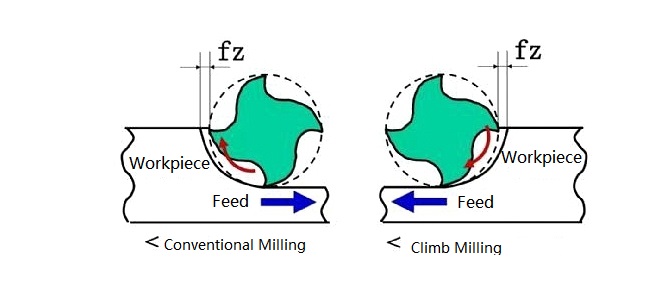

Climb milling and conventional milling are the two primary techniques in machining operations. Climb milling, where the cutter rotates in the same direction as the feed, offers smoother finishes and extended tool life but demands a more rigid setup. On the other hand, conventional milling, where the cutter rotates against the feed direction, provides greater stability on less rigid setups and is typically used for roughing operations. Your choice between these two methods should depend on factors like material type, machine rigidity, and the desired surface finish.

Understanding the nuances between these two methods is crucial for manufacturers, machinists, and even engineering students who are looking to optimize their milling operations. This guide will delve into the technical differences, advantages, and ideal applications of climb and conventional milling, equipping you with the knowledge to make informed decisions in your machining projects.

What is Milling?

Milling is a machining process that uses rotary cutters to remove material from a workpiece, progressively shaping it into the desired form. The process can be classified into several types of operations, including face milling, peripheral milling, and more, each defined by the tool’s position and the type of cut it makes.

Milling Machines

Milling machines come in various configurations, with the most common being horizontal and vertical mills. These machines consist of key components like the spindle, table, and cutting tool, each playing a vital role in the machining process. The choice between a horizontal or vertical mill depends largely on the workpiece and the type of milling required.

Milling Cutters

The cutting tools used in milling, known as milling cutters, are available in numerous shapes and sizes. They can be made from materials like high-speed steel (HSS), carbide, or cobalt, each suited for different machining conditions. The cutter’s geometry and material significantly influence the quality of the finish and the tool’s longevity.

What is Climb Milling

Climb milling, also known as down milling, occurs when the cutter rotates in the same direction as the feed of the workpiece. This technique causes the chip to start at the thickest point and get thinner as the cut progresses, resulting in a more controlled and smoother finish.

Advantages of Climb Milling

- Surface Finish Quality: One of the standout benefits of climb milling is its ability to produce a smoother surface finish. The cutting action minimizes the chances of material tearing, leaving behind a cleaner, more precise surface. For instance, climb milling can achieve surface roughness (Ra) values as low as 0.4 µm, compared to the rougher finishes often seen in conventional milling.

- Tool Life Enhancement: Climb milling significantly reduces friction between the tool and the workpiece, leading to less heat generation and extended tool life. Studies have shown that tool life can be up to 50% longer in climb milling due to these lower cutting forces.

- Reduced Cutting Forces: The direction of the cutting forces in climb milling helps to press the workpiece down into the table, reducing vibration and the chances of tool chatter. This reduction in cutting force, sometimes by as much as 30%, can also enhance machine performance and accuracy.

- Better for Harder Materials: Climb milling is particularly effective when working with hard materials like titanium or hardened steels. The reduced cutting forces help in managing the toughness of these materials, making the milling process more efficient.

Disadvantages of Climb Milling

- Potential for Tool Pull-In: One of the risks associated with climb milling is the tendency for the tool to pull into the workpiece, especially if the machine is not rigid enough. This can lead to tool deflection and inaccuracies in the cut.

- Requires More Rigid Machines: Due to the potential for tool pull-in, climb milling demands a more rigid machine setup. Machines that lack the necessary rigidity might not handle climb milling well, leading to poor surface finishes and potential damage to the workpiece.

- Not Suitable for All Materials: While climb milling excels with harder materials, it may not be ideal for softer materials like plastics or aluminum. These materials can lead to excessive wear on the cutting edge, reducing tool life and cutting efficiency.

Ideal Applications

Climb milling is ideal for finishing operations where a high-quality surface finish is required. It is commonly used in industries like aerospace and automotive, where precision and surface quality are critical. Modern CNC machines, which are typically more rigid and capable of high-precision operations, are particularly well-suited for climb milling.

What is Conventional Milling

Conventional milling, or up milling, occurs when the cutter rotates against the direction of the feed. This means that the chip starts thin and increases in thickness, which can result in a rougher cut and more friction between the tool and the workpiece.

Advantages of Conventional Milling

- Better for Roughing Operations: Conventional milling is often preferred for roughing operations where the goal is to remove a large amount of material quickly. The process is more stable and less prone to tool pull-in, making it safer for aggressive material removal.

- Less Risk of Tool Pull-In: The nature of conventional milling means that the tool is less likely to be pulled into the workpiece. This reduces the risk of tool deflection, making it a safer choice for less rigid setups or older machines.

- More Forgiving on Less Rigid Setups: Conventional milling can be used on a wider range of machines, including those that are less rigid. This makes it a versatile option for workshops that may not have access to the latest, most rigid milling equipment.

Disadvantages of Conventional Milling

- Poorer Surface Finish: Due to the increased friction and the way the chip forms, conventional milling generally results in a rougher surface finish. This can be a significant drawback in applications where surface quality is critical.

- Increased Wear on Cutting Tools: The higher friction and cutting forces involved in conventional milling can lead to increased tool wear. This not only shortens the tool’s lifespan but also increases the overall cost of the operation.

- Higher Cutting Forces: Conventional milling typically requires 20-30% more cutting force than climb milling. This increased force can lead to greater wear on the machine and the tool, and may also affect the precision of the operation.

Ideal Applications

Conventional milling is best suited for roughing operations, particularly when working with less rigid machine setups or older equipment. It is also a good choice when machining softer materials like aluminum, where the risk of tool wear is lower.

When to Choose Conventional or Climb Milling

Choosing between climb and conventional milling depends on several key factors:

- Material Being Machined:

If you’re working with harder materials like steel or titanium, climb milling is often the better choice due to its lower cutting forces and better surface finish. For softer materials, conventional milling may be more appropriate to avoid excessive tool wear.

- Machine Rigidity:

The rigidity of your milling machine is a critical factor. Climb milling requires a very rigid setup to prevent tool pull-in and achieve accurate results. If your machine setup is less rigid, conventional milling is likely the safer and more reliable option.

- Desired Surface Finish:

If a smooth surface finish is a priority, climb milling is generally superior. It minimizes friction and material tearing, leading to a cleaner finish. Conventional milling, while rougher, might be adequate for applications where surface quality is less critical.

- Type of Operation:

For roughing operations, where large amounts of material need to be removed quickly, conventional milling is typically more efficient. For finishing operations, climb milling is preferred due to its ability to achieve finer surface finishes and tighter tolerances.

Technical Comparison: Climb vs Conventional Milling

Tool Engagement and Cutting Forces

In climb milling, the cutting forces are directed into the workpiece, pressing it down into the table. This reduces vibration and tool chatter, making the process more stable. In contrast, conventional milling tends to lift the workpiece, which can cause deflection and inaccuracies if the setup is not sufficiently rigid.

Data shows that climb milling can reduce cutting forces by as much as 30%, which directly impacts tool life and the quality of the surface finish. Conversely, conventional milling often requires 20-30% more force, which can increase tool wear and potentially lead to higher production costs.

Surface Finish and Tolerances

Climb milling generally produces a superior surface finish due to its lower friction and smoother cutting action. It is not uncommon for climb milling to achieve surface roughness (Ra) values as low as 0.4 µm, compared to 1.2 µm or more in conventional milling. This difference is critical in industries where surface finish and tolerance are of utmost importance.

When it comes to tolerances, climb milling can achieve tighter tolerances, sometimes as fine as ±0.01 mm. This makes it the preferred method for finishing operations where precision is crucial.

Material Considerations

The choice between climb and conventional milling also depends on the material being machined. Hard materials like steel and titanium benefit from the reduced cutting forces in climb milling, which helps manage the material’s toughness. On the other hand, softer materials like aluminum and plastics are often better suited for conventional milling to avoid excessive tool wear.

Machine and Tooling Requirements

Climb milling demands a rigid machine setup to prevent tool pull-in and achieve accurate results. The tooling should also be carefully selected, with sharp tools being essential to minimize cutting forces and achieve the desired surface finish. Conventional milling is more forgiving, allowing for a wider range of machines and tooling options, but it may require more frequent tool changes due to increased wear.

Safety Considerations

Climb milling poses certain safety risks, particularly the potential for tool pull-in, which can lead to unexpected tool breakage or damage to the workpiece. To mitigate these risks, it’s crucial to ensure that the machine is rigid enough and that all safety protocols are followed. Conventional milling, while generally safer, still requires careful attention to machine setup and tooling to prevent accidents.

Practical Tips for Milling Operations

Choosing the Right Milling Method

When selecting between climb and conventional milling, consider the material, machine rigidity, and the specific requirements of the operation. For example, if precision and surface finish are priorities, climb milling is likely the better choice. If stability and safety are more important, particularly in roughing operations, conventional milling may be the way to go.

Best Practices for Climb Milling

To optimize climb milling operations, ensure that your machine setup is as rigid as possible. Use sharp tools and optimize feed rates to minimize cutting forces and achieve the best surface finish. Regularly monitor tool wear and replace tools as needed to maintain high precision and surface quality.

Best Practices for Conventional Milling

In conventional milling, it’s essential to use appropriate cutting fluids to reduce friction and heat generation. Monitoring tool wear closely can prevent excessive tool changes and maintain efficiency. Additionally, controlling feed rates is crucial to prevent tool chatter and achieve a consistent finish.

Troubleshooting Common Issues

If you encounter poor surface finishes in climb milling, check the rigidity of your machine setup and ensure that the tools are sharp and properly aligned. For conventional milling, if tool wear is excessive, consider adjusting the cutting speed and feed rate, or switch to a more durable tool material like carbide.

The Future of Milling Techniques

Technological Advances

The ongoing advancements in CNC technology are continually improving the capabilities of both climb and conventional milling. CNC machines are becoming more rigid and precise, allowing for more effective use of climb milling in a broader range of applications. Additionally, the integration of AI and machine learning is beginning to optimize milling operations in real-time, adjusting parameters to achieve the best possible outcomes.

Emerging Trends

Hybrid milling methods, which combine aspects of both climb and conventional milling, are gaining traction. These methods aim to harness the advantages of both techniques, particularly in complex machining operations where traditional methods may fall short. As new materials are developed, especially in aerospace and medical industries, milling strategies will continue to evolve to meet these new challenges.

Conclusion

For high-precision operations with modern equipment, climb milling is often the best choice. If you are working with older equipment or need to remove large amounts of material quickly, conventional milling is likely more suitable. Always consider the specific needs of your project, including material type, machine capabilities, and desired outcomes, when choosing between these methods.

FAQs

Which is better for surface finish: climb or conventional milling?

Climb milling generally provides a better surface finish due to reduced friction and cutting forces. Conventional milling can result in a rougher finish due to the increased friction between the tool and the workpiece.

Can I use climb milling on all types of materials?

Climb milling is best suited for harder materials like steel and titanium. It may not be ideal for softer materials like aluminum, which can cause excessive tool wear and lead to less accurate cuts.

When should I use conventional milling?

Conventional milling is ideal for roughing operations, particularly on older machines or setups with less rigidity. It is also more suitable for softer materials where tool wear is less of a concern.

How do I choose between climb and conventional milling?

Consider the material, machine rigidity, and desired surface finish. Use climb milling for hard materials, high precision, and smooth finishes. Opt for conventional milling for roughing operations, especially with less rigid setups or softer materials.