The use of CNC lathes is very widespread. If you’ve never encountered CNC lathe before or have only a vague understanding of them, don’t worry. This article will introduce you to the relevant knowledge about CNC lathes.

What is a Lathe?

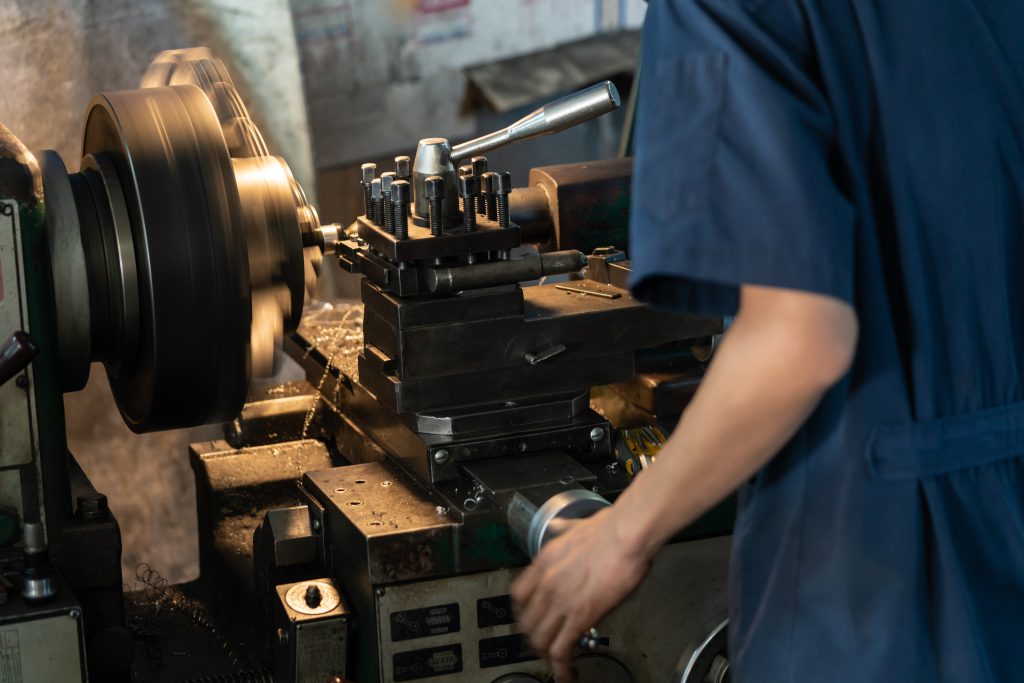

A lathe is a machine tool used to cut, shape, and drill rotating workpieces, mainly for shaping the outer surface and inner hole of metal materials. It can also be used for drilling, grooving, and threading.

History of CNC Lathes

Lathes have a long history, dating back to ancient Egypt. Back then, lathes were made of pulleys and a bow-shaped rod. People used wood, rotating it around a central axis and shaping it with cutting tools. Nowadays, lathes use computer technology to produce items automatically, reducing the need for manual labor. CNC lathes are a product of the continuous development of lathes and computer technology. In the 1960s, CNC technology started being used in lathes, and it rapidly expanded in the 1970s.

Differences Between Turning and Milling

Turning and milling are both metalworking processes, but they operate differently. When turning, the cutting tool is held stationary while the workpiece rotates to remove excess material. Therefore, turning produces shapes with rotational symmetry, such as spheres or cylinders. In contrast, milling involves a rotating tool processing a fixed workpiece to create various shapes, mostly surfaces and grooves.

Definition of CNC Lathes

CNC stands for Computerized Numerical Control, which means controlled by computerized numbers. A CNC lathe is a highly automated machine that, through computer instructions, can automatically produce the needed workpieces.

Types of CNC Lathes

Lathes can be classified based on their functions such as relieving lathes, copying lathes, combination lathes, and saddle lathes, and so on. Besides, CNC lathes can be classified in different ways, such as by the position of the main spindle and the number of axes. Below are some examples.

Based on the functions:

- Relieving lathe

Relieving lathes are suitable for processing parts with thread-like and complex shapes. They are used for hobbing or shaving gears with a module ranging from 1 to 12mm. These lathes achieve high machining precision and produce smooth surfaces.

- Copying lathe

Copying lathes can automatically process shapes and sizes, leading to high productivity. They are suitable for machining intricate shapes and for large-scale production.

- Combination lathe

A combination lathe can be used not only for turning but also, with the help of attachments, for processes like grinding, drilling, and milling.

- Saddle lathe

The saddle lathe is shaped like a saddle and is used for machining parts with large radial dimensions and small axial dimensions. It is widely used across various applications.

Based on the position of the main spindle:

- Horizontal CNC lathe

A horizontal CNC lathe is named so because its main spindle is parallel to the horizontal plane. Typically, this type of lathe can process two workpieces simultaneously, offering strong stability and suitability for machining tougher materials.

- Vertical CNC lathe

A vertical CNC lathe is named so because its main spindle is perpendicular to the horizontal plane. This lathe is easy to operate and is suitable for machining small and high-precision workpieces.

Based on the number of axes:

- Dual-axis CNC lathe

A dual-axis CNC lathe has X and Z axes, allowing it to carry out end-face machining, outer diameter/inner diameter machining, basic circular machining, drilling, and tapping, but it cannot be used for milling.

- 3-axis CNC lathe

A 3-axis CNC lathe has X, Z, and C axes, with an added live tooling system that can be used for boring, drilling, and milling operations.

- 4-axis CNC lathe

A 4-axis CNC lathe has X, Z, C, and Y axes, and it can be used to manufacture complex machinery and perform off-center operations.

- 5-axis CNC lathe

A 5-axis CNC lathe has a second turret, allowing it to operate two tools at the same time, which speeds up the machining process.

Components of CNC Lathes

To understand CNC lathes, you need to grasp their components. Here are some examples.

Input/Output Device

The keyboard is typically the input device for CNC lathes, and operators obtain output information from the display screen.

Numerical Control Device

The numerical control device consists of hardware and software. The code for machining parts is first stored in the numerical control device. Then, the device processes and calculates the coded information. Finally, it distributes the calculated results to the servo systems of the machine tool in the form of digital signals.

Servo System

The servo system is responsible for carrying out instructions from the numerical control system, controlling the position and speed of the worktable automatically.

Main Body

The main part of a CNC lathe is responsible for making parts. It includes the CNC lathe bed, spindle, headstock, tailstock, chuck, tool turret, and foot pedals. Compared to regular lathes, CNC lathes have a more complex design, their manufacturing process is more precise, and they produce higher accuracy in their products.

Advantages of CNC Lathes

If you’re looking to buy a CNC lathe, it’s definitely because it can help you in production. Compared to traditional lathes, CNC lathes have many advantages:

- Reducing human errors.

- Improving machining precision.

- Lowering costs.

- Expanding production capacity.

Applications of CNC Lathes

Wherever there is mechanical machining, you’ll find CNC machines. That’s why CNC lathes have a wide range of applications. Here are three examples.

- Metal Processing

CNC lathes can perform drilling, cutting, milling, and other processes, so they can be used to work on metals like copper and iron.

- Mold Making

CNC lathes can process complex parts, making it possible to manufacture intricate molds.

- Parts Manufacturing

CNC lathes are programmed with code and controlled by computers to automatically produce parts with high precision. This means they can fabricate parts with very strict size and quality requirements.

Safety Operating Procedures for CNC Lathes

Before Operation:

1. Personnel should wear work clothes, safety shoes, and protective eyewear, and avoid wearing gloves.

2. Do not move or damage warning signs installed on the lathe.

3. Do not place obstacles outside the lathe, and ensure there is sufficient working space.

4. When a task requires two or more people to collaborate, coordination is necessary.

5. Do not use compressed air to clean the machine, electrical parts, or the CNC unit.

6. Check if the lubrication system is functioning properly. If the lathe has not been used for a long time, manually lubricate the components.

7. The cutting tools should match the lathe model, and if a tool is severely damaged, replace it immediately.

8. When adjusting the tool position, do not forget to remove the adjusting tool from inside the lathe.

9. Check the chuck clamping status.

10. Before starting the lathe, ensure that the protective doors are closed.

During Operation:

1. Do not touch the chips with your hands; use a dedicated hook and brush for cleaning.

2. Do not touch the running spindle or any other parts by hand or in any way.

3. Do not measure or wipe the workpiece with rags, and do not clean the machine tool.

4. While the lathe is in operation, the operator should not leave their post. If there is any abnormality, the machine should be stopped immediately.

5. Do not open the protective door during the machining process.

6. When the workpiece extends more than 100mm from the lathe, protective measures must be in place at the extended position.

After Operation:

1. Clean up the chips and wipe down the machine tool.

2. Check if the oil wiper on the lathe’s guide rail is worn.

3. Check the condition of the lubricating oil and coolant, and add or replace them promptly when necessary.

4. After ensuring everything is in order, sequentially close the protective doors, the power on the CNC lathe panel, and the main power.

Buying CNC Lathes Consideration

If you’re considering buying a CNC machine tool, you can’t afford to miss the following information. Compared to regular machine tools, CNC lathes are more expensive. Therefore, when choosing a lathe, it’s important to think carefully and make a cautious choice. Different brands of CNC systems have varying strengths and weaknesses, so you need to match the CNC lathe to the products you intend to produce. The common CNC systems mainly include Germany’s Siemens, Japan’s Fanuc, and China’s Wuhan Huazhong system and Guangzhou system.

Compared to regular machines, CNC lathes require more advanced skills from operators. Operators must undergo specialized training in computer programming and related skills. Only trained and qualified professionals can operate CNC machines.

Conclusion

The above is the basic information about CNC lathes. If you want to learn more about CNC lathes, please contact us. Thank you for reading!