CNC Lathe Machines

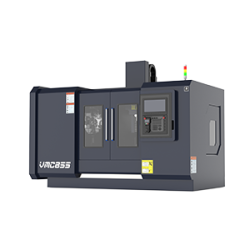

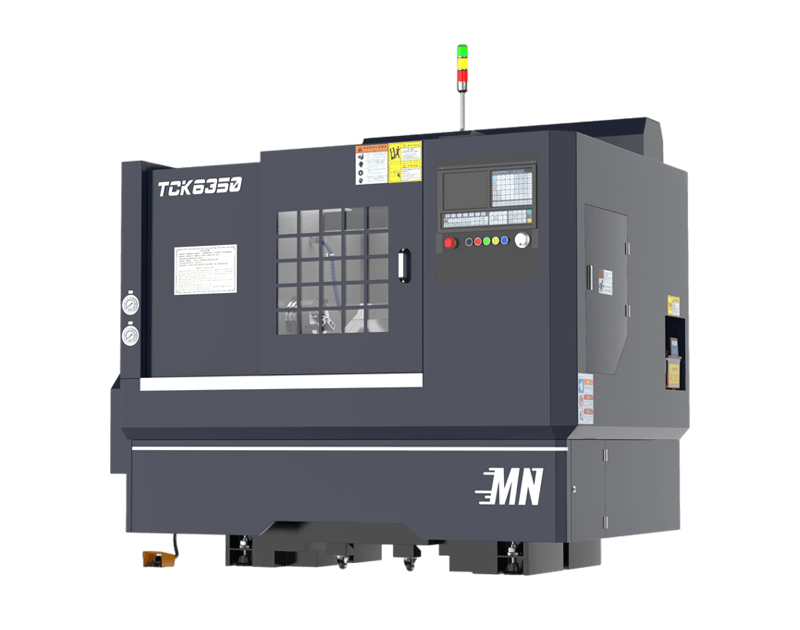

Minnuo CNC is a professional CNC lathe manufacturer and supplier in China, we have a professional CNC lathe manufacturing plant, which can provide precision automatic CNC lathe machine, heavy duty CNC lathe machine, vertical machining center, horizontal CNC machine and related parts and services. Want to buy high quality CNC lathe machine with absolute advantageous price, we can give you the price of used lathe machine the quality of new one, hurry up to contact us to get the favorable price!

CNC Lathe Machine For Sale

Factory Video

Minnuo Group Co., Ltd. is located in Jiangsu Province, China, and was founded in 1987. Currently, we have grown to become one of the leading CNC machinery manufacturers in China. With a factory area of 100,000 square meters and over 400 employees, we have an annual export value exceeding $80 million. We produce and manufacture CNC machine tools that are sold to more than 50 countries in the world, and we have professional product engineers to provide one-on-one guidance, so you can contact us if you need. We warmly welcome customers from all over the world to visit our factory.

The main purpose and characteristics of CNC lathe.

CNC lathes are mainly used for processing various shafts and disc parts. They can turn various threads, arcs, cones, and the inner and outer surfaces of rotating bodies. They can meet the speed requirements for high-speed chip removal of black and non-ferrous metals. They are suitable for efficient,large-scale, and high-precision processing of rotating parts in industries such as automobiles, motorcycles, electronics, aerospace, and military industry.

- CNC lathes adopt mechatronics integration design, with beautiful appearance, reasonable structure, low noise, and high positioning accuracy. They are widely used and easy to operate. They can automatically complete the internal and external circles, grooving, end face, taper, and various metric and imperial thread processing.

- The CNC system programming uses ISO international code and can be manually input through the keyboard.

- The spindle system has good rigidity and stepless speed regulation. The spindle has a large aperture and can be equipped with complete accessories. It is suitable for various complex shapes, long shafts, disc parts, etc. In addition, the machine tool has the characteristics of low speed and high torque, suitable for precision finishing of parts.

- The bed has high stiffness, and the bed guide rail is quenched and ground by ultrasonic frequency, with long service life and high precision.

- The longitudinal and transverse movements of the machine tool are driven by servo motors and precision ball screw transmission.

- The machine tool structure and transmission stiffness are higher than that of ordinary lathes, with high power utilization, suitable for strong and high-speed cutting.

- The machine tool is convenient to operate and the operation interface is user-friendly.

Main Components of CNC Lathe Machine

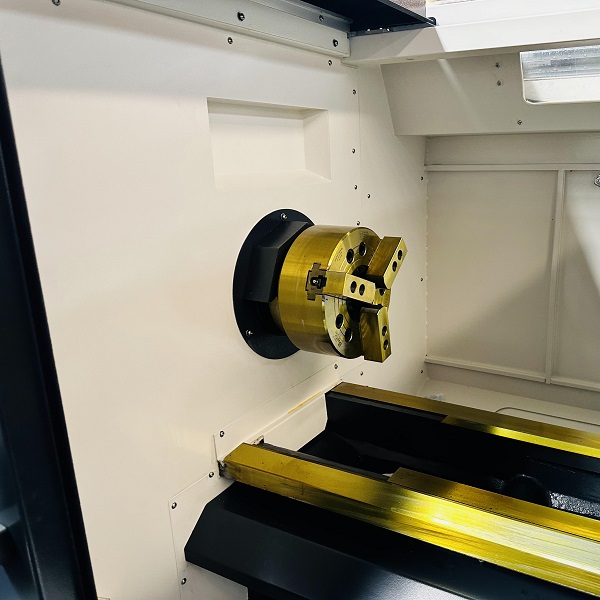

PRECISION CHUCK

Standard with Manual chuck,Optional: hydraulic chuck or pneumatic chuck

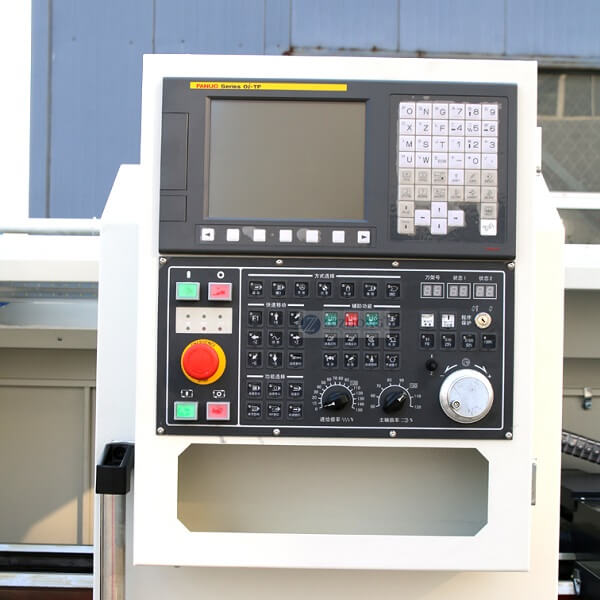

CNC CONTROL SYSTEM

Standard: GSk, Optional:Siemens, Fanuc, Syntec, Mit-subishi and others.

SPINDLE

105 spindle hole, three step spindle speed.

TOOL POST/TURRET

Standard with 4 station electrictool post, 6/8 station electric turret are optional.

QUENCHING ONE PIECE BED

Super audio quenching guide rail, one-piece casting with wider guide.

TAILSTOCK

Standard with manual tailstock

Optional: Hydraulic or pneu

matic type tailstock.

How to choose the right CNC lathe machine?

CNC machine tools are machine tools equipped with automation programs. Operators control CNC machine tools by inputting operation codes, enabling them to perform a series of complex and precise part processing actions. CNC machine tools are highly precise machining machines, and many factors need to be considered when purchasing them.

1.Determine the “family” of workpieces

To buy CNC machine tools, identify the objects, parts, programs, and categories of workpieces (e.g., box, rotary, irregular, plate). Determine the appropriate machining equipment by differentiating workpiece families.

2.Plan and design the process flow

Once the family of workpieces has been determined, we need to design an efficient process flow. This involves maximizing production efficiency and exploring the rational configuration of CNC machine tools with other equipment.

3.Determine the specifications and characteristics of the CNC machine tool

The process flow determines the specifications and characteristics of CNC machine tools. When selecting CNC machine tools, prioritize a simple structure that maximizes structural functions and meets production requirements without unnecessary features.

4.Determine the precision of the CNC machine tool

CNC machine tools are categorized based on their uses and precision levels. High-precision machining requires both accuracy and stability, so when selecting a high-precision machine tool, stability is a crucial factor to consider.

5.Select the CNC system for the CNC machine tool

Choose the CNC system of the machine tool wisely based on functional requirements, cost-effectiveness, after-sales service, and system lifespan.

6.Selection of the Automatic Tool Changer (ATC)

The ATC is critical for the CNC machine’s production quality. When selecting, choose a reliable one and consider factors like tool holder model, changing time, weight, and magazine capacity to ensure reliability.

7.Automatic exchange worktable and tool holder tools

The automatic exchange worktable is used for flexible manufacturing units, and its necessity depends on machining requirements. The choice of tool holder and tools depends on the machining process, and their selection should be rational based on the machining requirements.

Getting Your CNC lathe machine

We have a professional technical team, come and compare prices and services

Frequent Asked Question

A:-The appearance are similar, but the models, parameters and configurations are different, so the prices are different. The better configuration, the higher prices. If you want to get an exact quotation, please contact customer service.

A:-Yes, we can. Please provide the specification for the machine you need, and tell us your requirements.

A:-Please provide the requirements of the products you need to process: drawings, dimensions, size of workpeices etc.

we will recommend the suitable model for you according to the products you need to process.

A:FOB, CFR and CIF all acceptable.

A :T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight .

A: 1 set .(Only some low cost machines will be more than 1 set )

© 2022 All rights Reserved. Design by MINNUO Group.

- cncitd@minnuo.com

- +8613295238763