What is a CNC Machine?

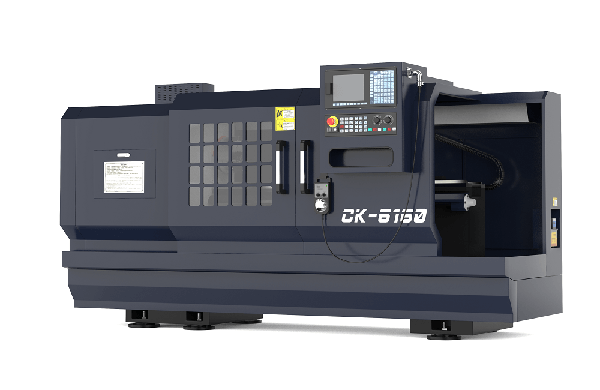

CNC machine tools are computer-controlled automated machine tools. Operators use CAD and G-codes to achieve efficient production. CNC machine tools can be used for turning, milling, drilling, grinding, cutting, carving, and other operations on a variety of materials.

Compared to manual machine tools, CNC machine tools offer higher levels of automation, increased precision in products, and enhanced production efficiency. This not only saves on labor and costs but also leads to improved profitability.CNC machine tools are extensively used in the manufacturing industry, spanning across sectors like aerospace, medical equipment, electronic components, and various other fields.

Types of CNC Machines

CNC machine tools are classified into various types based on their functions and applicable fields. Here are some common types of CNC machine tools:

- CNC Lathes

- CNC Milling Machines

- CNC Machining Centers

- CNC Drilling Machines

- CNC Boring Machines

- EDM Machines

- CNC Punching Machines

- CNC Routers

- Water Jet Machines

- CNC Laser Cutting Machines

- CNC Grinders

- CNC Welding Machines

10 CNC Machine Brands

Various CNC machine tool brands offer different user experiences, performance features, technical support, and after-sales services. Here is an introduction to the top ten CNC machine tool brands in recent years.

Yamazaki Mazak

Yamazaki Mazak is the biggest CNC machine tool manufacturer in Japan, consistently securing the top rank in global market share. The company serves customers in industries ranging from machinery, automotive, aerospace, energy, electronics, to healthcare.

Yamazaki Mazak provides a diverse selection of machine tools, which encompasses CNC lathes, turning centers, multitasking machines, CNC milling machines, horizontal machining centers, vertical machining centers, CNC laser machines, Flexible Manufacturing Systems (FMS), CAD/CAM software, and control systems.

Mazak has been at the forefront of innovation and technological research, with a global presence of 10 factories and 38 technology centers. Their diverse range of machine tools offers high design precision, fast speeds, and high reliability, enabling them to deliver comprehensive technical support services to customers.

Key Benefits:

- Intelligent, automated, high-precision, and high-speed production capabilities.

- Facilitates transparent assembly processes for enhanced accountability in quality management.

- Tailored global services to meet specific needs.

Trumpf

Trumpf, headquartered in Germany, holds the top position globally in the field of laser processing.

Trumpf Company has a long-standing commitment to researching industrial laser equipment and systems to develop products that cater to customers’ processing requirements.

Trumpf is primarily known for manufacturing laser cutting machines, punch presses, press brakes, and welding equipment.Laser cutting machines are among Trumpf ‘s top products, widely utilized in industries like automotive, aerospace, electronics, and healthcare for their precision and versatility.

In the CNC machine tool industry, Trumpf has built a solid reputation for excellent product quality and outstanding customer service.

Key Benefits:

- Cutting-edge laser technology

- Providing tailored local services for customers

- Offering a diverse range of products

DMG MORI

DMG MORI is a multinational company that combines the strengths of German company DMG and Japanese company Mori Seiki.

As a top-tier manufacturing supplier, DMG MORI’s product line comprises vertical machining, horizontal machining, three-axis, four-axis, five-axis, mill-turn composite machining centers, ultrasonic/laser machining centers, and more.

When it comes to design, DMG MORI has always been a top player in the industry, manufacturing the unique LaserTec 65 hybrid machining center that is capable of processing complex shapes such as geometric forms.

As a frontrunner in the machine tool industry, DMG MORI is constantly innovating and pushing boundaries in sectors like aerospace, automotive, and rapid prototyping. When it comes to precision machining, DMG MORI’s solutions are always the top choice.

Moreover, DMG MORI offers highly user-friendly post-sales services, including a three-year warranty. By blending technology with service and embodying a philosophy of wholehearted dedication to customer satisfaction, DMG MORI has garnered worldwide acclaim.

Key Benefits:

- Leading in technology, strong innovation capabilities

- Committed to sustainable development

- Globalized customized services

MAG

MAG is headquartered in Germany and operates as a group company.MAG owns multiple machine tool manufacturing companies and control system companies, featuring numerous renowned brands that offer customers comprehensive and systematic customized product solutions.

MAG produces products such as lathes, milling machines, grinding machines, and gear honing machines, covering a wide range of fields including agriculture, industry, transportation, and energy.

In addition, MAG boasts advanced manufacturing technologies and a diverse product line, able to offer a comprehensive set of solutions to help customers boost production efficiency, increase productivity, and ultimately reduce manufacturing costs.

Key Benefits:

- Global presence with tailor-made services

- Extensive experience across various industries

- Leveraging state-of-the-art processing technologies for optimal results

Haas Automation

Haas Automation, based in the United States, is the world’s largest supplier of machine tools.Haas primarily specializes in CNC vertical and horizontal machining centers, CNC lathes, and rotary products. Their products are known for their high performance and excellent quality.

Haas has always adhered to the concept of producing high-precision and durable machine tools, continuously optimizing machine performance, pursuing high-efficiency production, and developing new machine models and functions. As a result, Haas possesses a strong competitive advantage in terms of both price and quality.

Haas has always prioritized meeting customer needs and improving quality, never slacking in customer service and product innovation. This commitment is a key factor in Haas’s worldwide reputation.

Key Benefits:

- Budget-friendly prices, top-notch quality

- Global sales and service network

- Strong culture of innovation

Hardinge

Hardinge, based in the United States, has a rich history spanning over a century. The company specializes in designing and manufacturing cutting machine tools and related tool accessories for processing precise and ultra-precise products.The products mainly consist of lathes and fixtures, with applications primarily focused on high-tech fields such as aerospace and defense industries.

Hardinge has rapidly expanded in scale and product variety, currently owning eight brands and holding multiple technology patents.Furthermore, Hardinge has been committed to delivering convenient and top-notch services to its customers. Whether in product development or customer service, Hardinge has always been dedicated to continuous improvement.

Key Benefits:

- Ultra-precise machining

- Advanced digital manufacturing techniques

- Globalized customized services

AMADA

AMADA is a Japanese brand renowned for producing sheet metal processing machinery and cutting products known worldwide for their precision, reliability, and efficiency.It offers a variety of advanced CNC punch presses, press brakes, laser cutting machines, and other sheet metal processing machinery. These products find wide applications in industries such as power generation equipment, metallurgy, shipbuilding, automotive, and more.

AMADA is a leading force in the sheet metal machinery industry, boasting 83 branches worldwide. They excel in integrating product development, design, manufacturing, training, and after-sales service under one umbrella.

Key Benefits:

- Extensive experience in sheet metal processing with cutting-edge technology

- High-quality products, excellent performance, strong safety features

- Integrated marketing network

Okuma

Okuma is a comprehensive Japanese company that manufactures machine tools and CNC systems, and it is also the largest producer of gantry machining centers in Japan.Okuma manufactures a variety of CNC lathes, turning centers, vertical and horizontal machining centers, gantry machining centers, and CNC grinding machines. Their products are known for their excellent rigidity, high cutting efficiency, and precision, widely used in industries such as aerospace and automotive manufacturing.

Okuma, as a century-old company, has been consistently gaining global recognition due to its willingness to invest heavily in product research and development. This commitment allows for continuous improvements in their machine tool performance, earning them worldwide acclaim. Additionally, most of Okuma’s products are used for export purposes.

Key Benefits:

- High product quality, long lifespan, user-friendly operation

- A comprehensive company offering machine tools and CNC systems

- Globalized customized services

Makino

Makino is a leading manufacturer and brand of CNC machine tools. They offer a wide variety of CNC machine tools, including horizontal and vertical machining centers, electrical discharge machining (EDM) machines, and wire EDM machines. Their products cater to various CNC machining requirements.

If you are looking for high-quality machining, then choosing the Makino brand is a great option. Whether you are in aerospace manufacturing or any other industry, Makino always has a product that suits your needs.

Makino has always been at the forefront of digital innovation and mechanical design. It has assembled a dedicated team of experts for product research and development, committed to creating top-of-the-line CNC machine tools. Makino’s commitment to prioritizing quality has garnered global acclaim and praise.

Key Benefits:

- Exceptionally high precision and durability

- Digitized production processes

- Embracing sustainable development principles

EMAG

EMAG is a German brand and one of the most prominent CNC inverted machine tool manufacturers in the world. It is widely recognized that machine tools manufactured in Germany are renowned for their high quality and reliability, and EMAG is no exception.

With extensive manufacturing experience, EMAG primarily produces products such as lathes, milling machines, machining centers, and grinding machines. These products find their main applications in industries such as automotive manufacturing, mechanical engineering, aerospace, and petrochemicals.

As a longstanding company, EMA has managed to stay relevant by prioritizing innovation and technological advancements, ensuring the delivery of high-quality products and services to its customers.

Key Benefits:

- Robust technological capabilities

- Strong spirit of innovation

- Globalized customized services

Factors to Consider Purchasing

When selecting a brand of CNC machine tools, it is essential to consider the following factors.

- Performance Metrics:

When selecting a CNC machine tool brand, it’s crucial to evaluate performance parameters such as processing precision, speed, rigidity, and stability. Precision and quality are essential standards that determine the overall quality of the machine tool.

- Background Check:

Ensure to investigate the brand’s reputation and industry standing to determine its positive influence, guaranteeing high product quality and after-sales service.Review customer ratings and feedback to assess reliability.

- Innovation and Technology:

Determine if the brand invests in funds and manpower for continuous technological innovation, possesses a dedicated R&D team, has introduced new products in recent years, and holds a leading position in technology within the market.

- After-sales Service and Support:

A comprehensive service network ensures timely repairs. Professional technical support and training can optimize the performance of machine tools.

- Environmental Protection and Energy Efficiency:

Check if the brand complies with environmental standards to reduce energy consumption and production costs, safeguarding the environment.

Future Trends and Challenges

CNC machine tools are indispensable in today’s manufacturing industry. Below are some future trends and challenges to consider.

In the future, CNC machine tools will become increasingly intelligent and digitalized. Technologies such as artificial intelligence and cloud computing will be widely adopted to enhance the production efficiency and automation level of CNC machine tools.With the continuous improvement and advancement of machining technology, emerging technologies will continuously enter the mainstream market. Flexible manufacturing systems will make production processes more flexible and intelligent. Energy conservation, emission reduction, and green manufacturing will also remain constant goals in industrial production efforts.

The rapid pace of technological advancements necessitates substantial financial and human resources for product development and updates. There is a high demand for top-tier technical talent. While digitization and automation bring convenience, cybersecurity precautions must be taken to prevent system vulnerabilities from cyber attacks.The global market competition continues to expand, leading to increased demands on the supply chain. As traditional and modern practices collide, the imperative for companies to undergo transformation becomes unstoppable. To secure long-term growth, brands must prioritize continuous innovation, elevate their technological prowess, ensure service quality, and navigate the path towards sustainable development.

Conclusions

The above is all about CNC machine tool brands. I believe you now have a basic understanding of CNC machine tool brands. If you want to learn more about CNC machine tools, please contact us. CNC machine tools produced by Minnuo Group are trustworthy, and we look forward to further communication and cooperation with you. Thank you for reading!