Are you confused about how much CNC machines cost? Understanding these factors will help you make an informed decision.

The price of CNC machines depends on a variety of factors such as brand, model, features, and after-sales service. In general, basic CNC machines range from tens of thousands to hundreds of thousands of dollars, while high-end models can exceed several hundred thousand dollars. Knowing these key points will help you choose the CNC machine that’s right for you.

Next, we’ll go into detail about these factors and help you make the best choice.

What is a CNC Machine?

A CNC machine, or Computer Numerical Control machine, is a piece of equipment that uses computer programming to automatically control machining tools. It’s widely used in manufacturing industries to process various metals and non-metal materials. CNC machines are known for their high precision, efficiency, and ability to complete complex machining tasks, which makes them essential in modern manufacturing.

Common CNC Machine Prices

The price of CNC machines varies depending on the type and functionality. Below are the price ranges for common CNC machines, broken down into low, mid, and Advanceds:

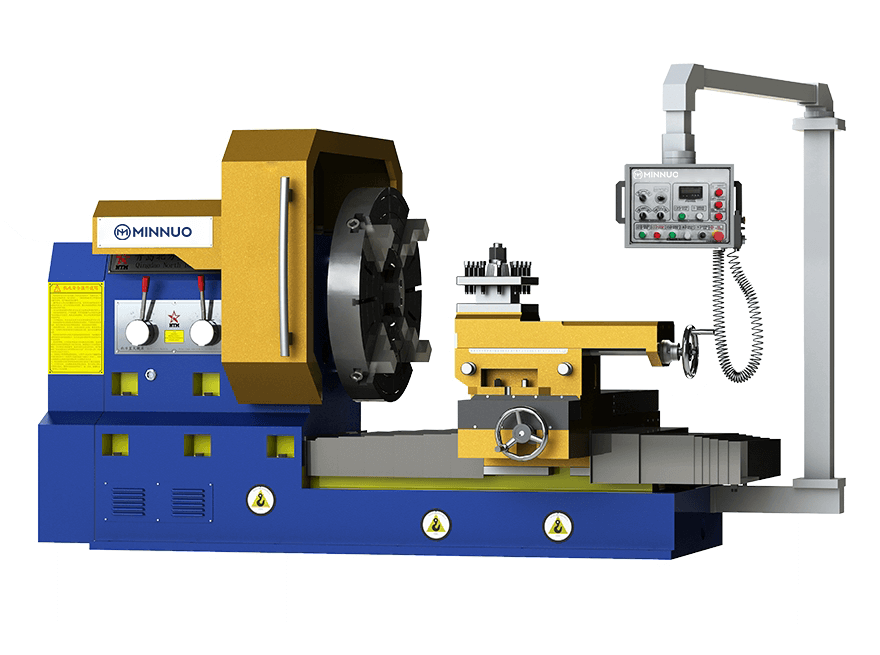

1. CNC Lathes

Junior: $30,000 – $50,000

– Good for small and startup businesses, basic turning functions.

Intermediate: $50,000 – $100,000

– Good for medium-sized businesses, more precision and stability.

Advanced: $100,000 – $200,000

– Good for large enterprises and high-precision machining needs, advanced turning technology and automation.

2. CNC Milling Machines

Entry-level: $2,000 – $5,000

– Good for beginners or light machining needs, basic milling functions.

Junior: $50,000 – $70,000

– Good for small and medium-sized businesses, basic milling functions.

Intermediate: $70,000 – $150,000

– Good for medium-sized businesses, more precision and multifunctional milling capabilities.

Advanced: $150,000 – $300,000

– Good for large enterprises and high-precision machining needs, advanced milling technology and automation.

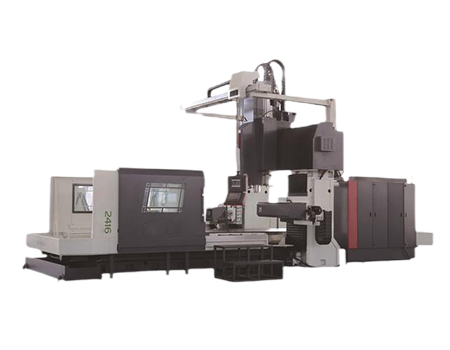

3. CNC Boring Machines

Junior: $100,000 – $150,000

– Good for small and medium-sized businesses, basic boring functions.

Intermediate: $150,000 – $300,000

– Good for medium-sized businesses, more precision and multifunctional boring capabilities.

Advanced: $300,000 – $500,000

– Good for large enterprises and high-precision machining needs, advanced boring technology and automation.

4. Laser Cutting Machines

Junior: $50,000 – $100,000

– Good for small and medium-sized businesses, basic laser cutting functions.

Intermediate: $100,000 – $200,000

– Good for medium-sized businesses, more precision and multifunctional laser cutting capabilities.

Advanced: $200,000 – $500,000

– Good for large enterprises and high-precision machining needs, advanced laser cutting technology and automation.

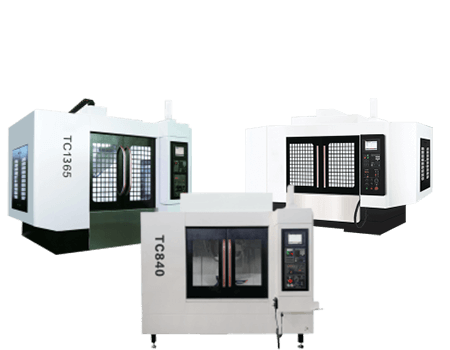

5. Machining Centers

Junior: $70,000 – $150,000

– Good for small and medium-sized businesses, basic machining functions.

Intermediate: $150,000 – $300,000

– Good for medium-sized businesses, more precision and multifunctional machining capabilities.

Advanced: $300,000 – $600,000

– Good for large enterprises and high-precision machining needs, advanced machining technology and automation.

Factors That Affect the Price of CNC Machines

The price of CNC machines is affected by many factors, including:

Brand: Well-known brands generally have higher prices due to better quality and after-sales service. The market positioning and reputation of the brand also affect the price.

Model and Features: More advanced models with more features are priced higher. For example, five-axis CNC machines, due to their complex machining capabilities, are generally more expensive than three-axis CNC machines.

Material: The quality of materials used in the machine directly affects the price. High-strength and wear-resistant materials increase the machine’s lifespan but also increase the cost.

Manufacturing Process: Advanced manufacturing processes and technologies increase costs. For example, machines using laser cutting and welding technologies are usually more expensive.

Control System: The complexity of the CNC machine’s control system also affects the price. Advanced control systems improve machining precision and efficiency but are more expensive.

After-Sales Service: Good after-sales service and warranty policies generally increase the machine’s price. Training, maintenance, and technical support provided by brand manufacturers are important factors.

Customization Requirements: Custom-made CNC machines based on specific customer needs are more expensive than standard models.

Market Demand: The supply and demand in the market also affect prices. Prices may rise during periods of high demand.

Other Considerations

In addition to price, consider the following factors when purchasing a CNC machine:

After-Sales Service: Choose brands and suppliers that offer good after-sales service and warranty policies. The quality of after-sales service directly affects the long-term use of the equipment.

Maintenance Costs: Understand the daily maintenance and upkeep costs of the machine to avoid hidden expenses during use. Improper maintenance can lead to equipment failures, affecting production efficiency.

Operational Training: Ensure the supplier provides operational training to ensure employees can use the equipment proficiently. Training improves operational efficiency and reduces equipment damage caused by improper use.

Equipment Upgrades: Consider the upgradeability of the equipment to allow future technological advancements without the need to purchase new equipment.

Environmental Requirements: Choose CNC machines that meet environmental standards to avoid additional costs and troubles caused by environmental issues.

How to Choose the Right CNC Machine

To choose the right CNC machine, you need to consider the following:

Identify your needs: You need to know what you want to machine, what materials you want to use, the size of the parts you want to make, and the precision you need. Based on your needs, you can choose the type of machine and the features you need. For example, if you are going to make small parts, you need a small CNC machine. If you need high precision, you need a high-precision CNC machine.

Budget: You need to choose a machine that is within your budget. Don’t just look at the price. You need to look at the performance and the quality. Sometimes, the cheapest machine is not the best machine. Sometimes, the cheapest machine will cost you more in maintenance and failures.

Choose the right supplier: You need to choose a good supplier that can provide good after-sales service and technical support. You need to check the qualifications of the supplier, the customer reviews, and the level of after-sales service to make sure you have a good partner.

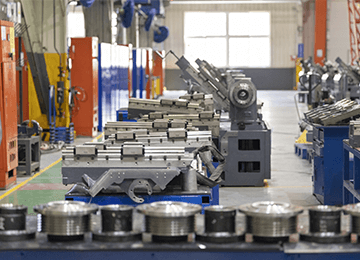

Visit the factory: You need to visit the supplier or the manufacturer to see the machine in person. By visiting the factory, you can get a better understanding of the performance and the quality of the machine.

Check the reviews: You need to check the reviews from other users. You need to see what other people say about the machine. By checking the reviews, you can get real feedback from real users. This will help you make a better decision.

Think about the future: You need to think about your future needs. For example, if you plan to expand your production, you need to choose a machine that can be expanded. This will save you money in the future.

Should You Consider Buying a Used CNC Machine?

There are pros and cons to buying a used CNC machine.

Pros: The price is lower, and it is cost-effective. If the machine is well-maintained, it can meet your needs. Buying a used machine will save you money on the initial investment and allow you to start production quickly.

Cons: There is a risk of wear and failure. The after-sales service is not as good as new machines. The quality and the performance of the used machine may not be as good as new machines. The lifespan of the used machine may not be as long as the new machine.

Things to consider: You need to check the usage and the maintenance history of the machine. You need to choose a reputable used machine supplier. You need to know the history of the machine to avoid buying a machine with major problems.

Professional inspection: You need to hire professional technicians to inspect the machine to make sure the machine meets your needs. The professional inspection will help you find the potential problems and reduce the risk of buying the wrong machine.

Where to Buy CNC Machines and Get After-Sales Service

There are three main places where you can buy a CNC machine:

Direct from the Manufacturer: When you buy direct from the manufacturer, you typically get a better price and better after-sales service. Machines you buy direct from the manufacturer are usually better quality and come with better after-sales support.

From a Dealer: When you buy from a dealer, you have access to more brands and more technical support. Dealers can offer you different brands and models to help you find the best machine for your needs.

On the Second-Hand Market: You can get a good deal on a machine on the second-hand market, but you need to be careful about the condition of the machine and the after-sales service. The machine will be cheaper, but you need to make sure it’s in good shape and has a good history.

How Much It Costs to Maintain and Take Care of Your CNC Machine

There are three costs associated with maintaining and taking care of your CNC machine:

Daily Maintenance: You need to look at and maintain your machine every day to make sure it’s running well. This includes lubricating, cleaning, and adjusting your machine.

Replacing Parts: You need to replace parts that wear out or break to keep your machine running well. You should regularly replace critical parts based on how much you use your machine to keep it running well.

Technical Support: You need to train your operators regularly to make sure they’re using your machine correctly and to make sure your machine lasts as long as possible. Training your operators will help prevent machine failures from operator error and will help you get more production out of your machine.

Conclusion

Now that you know what affects the price of a CNC machine and have a guide to help you choose the right one, you can make an informed decision when you buy. If you have any questions, please reach out to us.

Minnuo: Your Trusted CNC Machine Partner

Minnuo has been in the machine tool industry since 1987. With over 30 years of experience, you can trust Minnuo to give you the best CNC machines for your manufacturing needs. We’re committed to innovation and making sure you’re happy with your purchase. We’re your trusted partner for all your CNC machine needs. Experience the Minnuo difference today and take your manufacturing to the next level with our reliable and advanced CNC solutions.