In the world of machining, lathes play a crucial role in shaping and creating parts. CNC (Computer Numerical Control) technology has revolutionized this field, bringing precision and automation to both mini lathes and full-sized lathes.

Size and cost are the main differences between small lathes and large lathes. CNC mini lathes are compact, cost-effective, and ideal for small-scale, detailed projects, making them perfect for hobbyists and small workshops. CNC lathes, on the other hand, are larger, more versatile, and suitable for heavy-duty, industrial applications, offering advanced control and the ability to handle larger workpieces. When choosing between them, consider your project requirements, budget, workspace, and future expansion needs to make the best decision for your machining needs.

This article aims to explore the differences between CNC mini lathes and CNC lathes, helping potential buyers make informed decisions based on their specific needs and budget constraints.

What is CNC Mini Lathe

CNC mini lathes are compact, versatile machines designed for precision tasks. They are particularly suitable for hobbyists, small businesses, and educational purposes. Despite their small size, CNC mini lathes offer a range of capabilities similar to their larger counterparts.

Features of CNC Mini Lathes

To appreciate the functionality of CNC mini lathes, it’s essential to understand their key features:

- Compact Size and Portability: Typically measuring around 12-20 inches between centers, with a swing over bed of about 7-10 inches. Weighs between 70-150 pounds.

- Precision and Automation: Equipped with CNC technology, mini lathes provide high precision and repeatability, essential for detailed work.

- Ease of Use and Learning Curve: CNC mini lathes are often easier to learn and operate, making them ideal for beginners.

Applications

CNC mini lathes are utilized in various fields, showcasing their versatility and efficiency:

These lathes are used in jewelry making, model engineering, and educational settings. Typical projects include intricate parts, custom tools, and small-scale production runs.

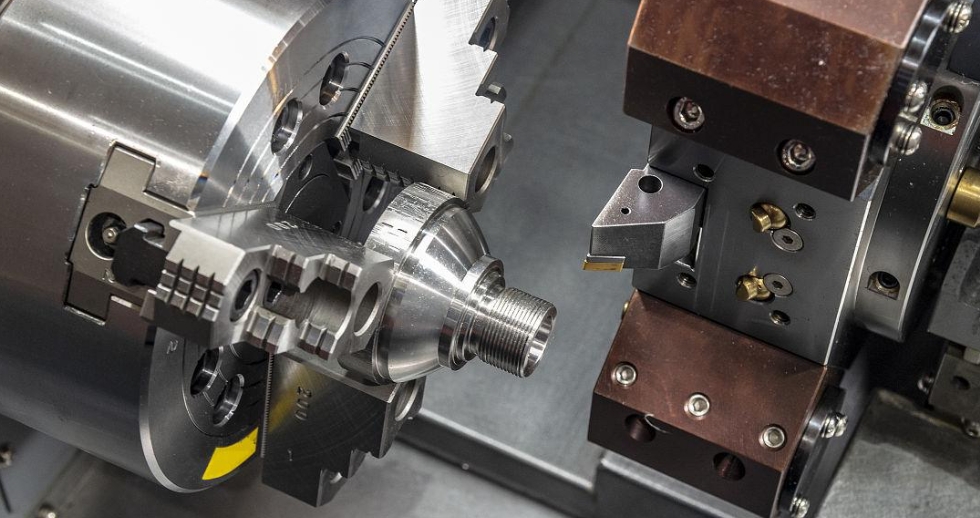

What is CNC Lathe

CNC lathes are larger, more robust machines designed for heavy-duty tasks and industrial applications. They offer greater versatility and can handle a wide range of materials and sizes.

Features of CNC Lathes

CNC lathes come with features that make them suitable for complex and large-scale operations:

Larger Size and Higher Robustness: Typically measuring 40-60 inches between centers, with a swing over bed of 12-20 inches. Weighs between 1,000-4,000 pounds.

- Advanced Precision and Automation: CNC lathes provide top-tier precision and efficiency, essential for high-quality production.

- Versatility in Operations: Capable of performing a variety of machining operations, including threading, drilling, and cutting.

Applications

CNC lathes are a staple in many industries, known for their capability to produce a wide range of parts:

These machines are prevalent in automotive, aerospace, and heavy machinery manufacturing. Projects include large shafts, complex automotive components, and high-precision aerospace parts.

Comparison of CNC Mini Lathes and CNC Lathes

Precision and Accuracy

When comparing the precision and accuracy of CNC mini lathes and CNC lathes, both offer high levels of precision, but their applications differ. CNC lathes generally provide higher accuracy for large-scale projects, while mini lathes excel in detailed, small-scale work.

Ease of Use

User-friendliness is a critical factor for both types of lathes. CNC mini lathes are typically easier to learn and use, making them suitable for beginners. In contrast, CNC lathes, with their advanced features, may require more expertise and experience.

Versatility and Flexibility

Both types of lathes offer versatility, but CNC lathes are more flexible due to their ability to handle a broader range of tasks and materials. Mini lathes are more specialized, focusing on smaller, more detailed work.

Portability and Space Requirements

Portability and space are significant considerations. CNC mini lathes are compact and portable, ideal for small workshops. Conversely, CNC lathes are larger and require more space, suited for industrial settings.

Cost Considerations

Cost is a crucial factor in choosing between CNC mini lathes and CNC lathes. Mini lathes are more affordable, with lower initial and operational costs. CNC lathes, while more expensive, offer higher capabilities and can justify their cost in large-scale operations.

Automation and Efficiency

Both types of lathes benefit from CNC automation, enhancing efficiency and precision. However, CNC lathes, with their advanced automation features, offer greater efficiency in high-volume production.

Advantages of CNC Mini Lathes

- Cost Efficiency:

CNC mini lathes provide an affordable entry point into CNC machining. They are less expensive to purchase and maintain, making them ideal for small businesses and hobbyists.

- Compact Size:

The small size of CNC mini lathes makes them perfect for limited spaces. They are easy to move and store, offering flexibility for workshops with space constraints.

- Ease of Learning:

With a simpler learning curve, CNC mini lathes are accessible to beginners. This ease of use makes them an excellent choice for educational purposes and hobbyists.

- Precision Work:

Despite their size, CNC mini lathes deliver high precision, suitable for detailed and small-scale projects. This precision makes them valuable for producing fine, intricate parts.

Advantages of CNC Lathes

- Versatility:

CNC lathes can handle a wide range of tasks and materials. Their versatility makes them suitable for various industries, from automotive to aerospace.

- Robustness:

Built for heavy-duty operations, CNC lathes are durable and capable of performing strenuous tasks. Their robustness ensures longevity and reliability in industrial applications.

- Advanced Control:

With sophisticated CNC control systems, CNC lathes offer advanced functionality. This control allows for complex machining operations, enhancing production capabilities.

- Larger Workpieces:

CNC lathes are designed to machine larger and heavier workpieces. This capability is essential for industries that require large-scale production and heavy-duty components.

Choosing the Right CNC Lathe for Your Needs

Assessing Your Requirements

To choose the right CNC lathe, assess your specific needs:

- Key Questions: What types of projects will you be working on? What materials will you use?

- Types of Projects and Materials: Consider the scale and complexity of your work.

Budget Considerations

Balance cost with your requirements:

- Initial Investment: Determine how much you can afford to spend initially.

- Operational Costs: Consider ongoing maintenance and operational expenses.

Space and Portability

Evaluate your workspace and need for portability:

- Workshop Size: Ensure you have enough space for the lathe.

- Portability Needs: Decide if you need a portable machine.

Skill Level and Learning Curve

Consider the user’s experience and learning curve:

- Experience: Choose a machine that matches your skill level.

- Training Needs: Be prepared for any training required to operate the lathe.

Future Expansion

Think long-term about your needs:

- Upgrade Potential: Consider if you may need to upgrade in the future.

- Scalability: Ensure the lathe can handle potential growth in your operations.

Conclusion

CNC mini lathes and CNC lathes each offer unique advantages: mini lathes are compact and cost-effective, ideal for small-scale, precise work, while full-sized CNC lathes provide greater versatility and robustness for heavy-duty, industrial applications. When deciding between the two, consider your specific project needs, budget, available workspace, and potential for future expansion to choose the best machine for your machining requirements.

FAQs

Are CNC mini lathes suitable for industrial applications?

CNC mini lathes are best for small-scale production and detailed work. For heavy-duty industrial applications, CNC lathes are more appropriate.

How much does a CNC mini lathe cost compared to a CNC lathe?

CNC mini lathes are generally more affordable, with lower initial and operational costs. CNC lathes are more expensive but offer greater capabilities.

Can a beginner use a CNC mini lathe?

Yes, CNC mini lathes are ideal for beginners due to their ease of use and shorter learning curve.