Choosing between a CNC router and a CNC mill can be challenging, especially given the nuances of each machine. While both are used for precision machining, they serve different purposes and excel in different areas.

If you need speed and versatility for softer materials like wood or plastic, choose a CNC router. For high precision and harder materials like metals, a CNC mill is the better choice.

This guide will break down the differences, advantages, and ideal applications for each, helping you make an informed decision.

CNC Technology

CNC (Computer Numerical Control) technology automates machining processes by using computer programs to control tools like routers and mills. This technology allows for precise, repeatable production of complex parts across various industries, from aerospace to manufacturing. By translating digital designs into accurate physical outputs, CNC machines enhance efficiency and reduce human error, making them essential in modern manufacturing.

Importance of Choosing the Right Machine for Specific Applications

Selecting the appropriate CNC machine is crucial for achieving optimal results. CNC routers excel with softer materials like wood and plastic, while CNC mills are better suited for precision work with metals. Choosing the wrong machine can lead to increased costs, lower quality, and unnecessary wear on the equipment. Understanding your project’s specific needs—such as material type and required precision—ensures that you use the right tool for the job, improving both efficiency and product quality.

Understanding CNC Routers

Before diving into the specific advantages and disadvantages of CNC routers, it’s important to understand what they are and the context in which they operate. By grasping the basics of how CNC routers function and where they are commonly used, you’ll be better equipped to determine whether this machine meets your needs.

What is a CNC Router?

A CNC router is a machine designed to cut, carve, and engrave materials like wood, plastic, and composites quickly and efficiently. It moves a rotating cutting tool along multiple axes, following precise computer-generated instructions.

Now that we have a basic understanding of what a CNC router is, let’s explore the industries where these machines truly shine. CNC routers are highly valued across various sectors due to their versatility and speed, particularly when working with specific materials.

Key Applications and Industries

CNC routers are widely used in industries that deal with large, flat materials. The ability to quickly and accurately process these materials makes CNC routers invaluable in several fields.

- Woodworking: Creating intricate patterns and shapes in wood.

- Plastics: Cutting and shaping plastic sheets for various products.

- Sign-Making: Engraving and cutting signs from materials like acrylic or wood.

While CNC routers are versatile and efficient, they are not without limitations. Understanding their strengths and weaknesses can help you decide if they are the right fit for your specific needs.

Advantages of CNC Routers

- Speed: High speed and efficiency, especially with large, flat materials.

- Versatility: Capable of handling a wide range of softer materials.

- Cost-Effective: Generally less expensive to purchase and maintain.

However, as with any tool, there are trade-offs. Let’s consider the potential downsides of using a CNC router, especially when compared to other machining options.

Disadvantages of CNC Routers

Precision Limitations: Not as precise as CNC mills, especially with metals.

Material Constraints: Struggles with harder materials, leading to quicker wear and tear.

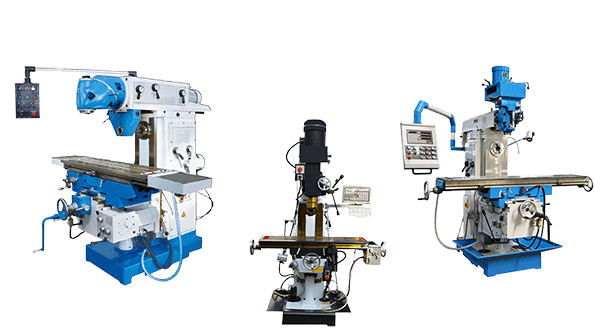

Understanding CNC Mills

As we shift our focus from CNC routers to CNC mills, it’s important to note that while both machines are used in precision machining, they cater to different requirements. CNC mills are designed for tasks that demand a higher level of accuracy and the ability to work with tougher materials.

What is a CNC Mill?

A CNC mill is a machine designed for high-precision machining of hard materials like metals. It uses rotating cutting tools to shape materials by removing excess material, allowing for intricate and detailed work.

With a basic understanding of what CNC mills are, let’s explore the industries and applications where these machines are most commonly used. CNC mills are essential in sectors where precision and material strength are critical.

Key Applications and Industries

CNC mills are indispensable in industries that require precision and durability. These machines are frequently employed in sectors where the stakes are high, and the margins for error are slim.

- Metalworking: Precision machining of metal parts and components.

- Aerospace: Creating high-tolerance parts for aircraft and spacecraft.

- Medical Devices: Manufacturing of complex, precise parts for medical equipment.

Now that we’ve identified where CNC mills are most useful, it’s time to delve into what makes them stand out. Understanding their advantages will help clarify why these machines are chosen for such demanding tasks.

Advantages of CNC Mills

- Precision: Capable of achieving tolerances as tight as 0.001 inches.

- Material Range: Can machine a wide range of hard materials, including metals.

- Durability: Built to handle tough materials with minimal wear.

Despite their strengths, CNC mills do come with some drawbacks. It’s important to consider these disadvantages when deciding whether a CNC mill is the right investment for your operation.

Disadvantages of CNC Mills

Cost: Generally more expensive to purchase and maintain.

Speed: Slower operation compared to CNC routers, especially with large parts.

Complexity: Requires more expertise to set up and operate.

Comparative Analysis

Now that we have a clear understanding of both CNC routers and CNC mills, it’s time to compare them directly. This comparative analysis will highlight the key differences in capabilities, operational aspects, and costs, helping you to choose the best machine for your needs.

Capabilities and Performance

When comparing CNC routers and CNC mills, it’s crucial to evaluate how each machine performs in terms of speed, precision, and material compatibility. These factors will ultimately determine which machine is better suited for your specific projects.

CNC Routers: Excel in speed and versatility, ideal for high-volume, less precise tasks with softer materials.

CNC Mills: Offer superior precision and are better for detailed, high-tolerance work with harder materials.

Performance is just one piece of the puzzle. Next, we’ll look at the operational differences between these two machines, which can significantly impact your workflow and ease of use.

Operational Differences

Operational efficiency is key when choosing between a CNC router and a CNC mill. Each machine has its own set of operational requirements, which can affect everything from setup time to maintenance routines.

Ease of Use: CNC routers are generally easier to set up and operate, making them more accessible to beginners.

Maintenance: CNC mills require more frequent and intensive maintenance due to the demands of machining hard materials.

Cost is often a deciding factor in choosing the right machine. Let’s break down the financial implications of investing in a CNC router versus a CNC mill.

Cost Considerations

The cost of owning and operating a CNC machine goes beyond the initial purchase price. Maintenance, material waste, and long-term durability are all factors that contribute to the overall cost-effectiveness of each machine.

Initial Cost: CNC routers are typically less expensive upfront.

Long-Term Costs: CNC mills can be more cost-effective over time for precision work, despite higher initial and maintenance costs, due to reduced material waste and longer machine life.

Practical Examples

Understanding the theory behind CNC routers and mills is important, but real-world examples can bring this comparison to life. By examining practical applications of each machine, you can better visualize how they might fit into your own operations.

CNC Routers in Action

CNC routers are particularly effective in industries where speed and versatility are prioritized. Let’s consider an example from the custom furniture industry, where these machines play a crucial role in meeting production demands.

Example: A custom furniture manufacturer uses a CNC router to produce large quantities of intricately designed wooden panels quickly, meeting tight deadlines without sacrificing quality.

While CNC routers excel in certain applications, CNC mills are indispensable in others, particularly in industries that demand extreme precision.

CNC Mills in Action

CNC mills are often the go-to choice in sectors where precision and material toughness are critical. Consider the aerospace industry, where the accuracy and reliability of each component can be a matter of life and death.

Example: An aerospace company uses a CNC mill to create high-precision metal components that meet stringent industry standards, ensuring the safety and reliability of their products.

Making the Right Choice

By now, you should have a clearer understanding of the strengths and weaknesses of CNC routers and CNC mills. But how do you translate this information into a decision? The following section will provide guidance on the key factors to consider, helping you choose the right machine for your specific needs.

Key Factors to Consider

Selecting the right CNC machine depends on several factors, including the type of material you’re working with, the precision required, and your budget. Let’s explore these considerations in more detail to help you make the best choice.

- Material Type: Softer materials like wood or plastic favor CNC routers, while metals and hard materials require CNC mills.

- Precision Requirements: High precision and tight tolerances necessitate a CNC mill.

- Production Volume: Large-scale, high-speed production is more suited to CNC routers.

- Budget: Consider both initial investment and long-term maintenance costs.

Now that you understand the key factors, you can make a more informed decision. Let’s simplify this process with a decision-making framework that aligns your specific needs with the strengths of each machine.

Decision-Making Framework

Choosing the right CNC machine can feel overwhelming, but it doesn’t have to be. By considering your project as a character in a story, you can quickly identify which machine is the best fit.

- For Versatility and Speed: Choose a CNC router if your projects involve softer materials and high-volume production.

- For Precision and Durability: Opt for a CNC mill if your work requires high precision and involves harder materials.

Future Trends and Innovations

As technology advances, the capabilities of CNC routers and mills continue to evolve. Staying informed about these trends will help you make forward-thinking decisions, ensuring that your investment remains relevant in the years to come.

Emerging Technologies

The line between CNC routers and mills is becoming increasingly blurred, thanks to innovations like hybrid machines and AI-driven toolpath optimization. These advancements are making CNC machining more efficient and accessible than ever before.

- Hybrid Machines: Combining the speed of routers with the precision of mills.

- AI-Driven Toolpath Optimization: Making CNC machines smarter and more efficient, further blurring the lines between routers and mills.

By understanding these trends, you can anticipate how the CNC landscape might change and position your business to take full advantage of these advancements.

Conclusion

Selecting the right CNC machine depends on your specific needs. Whether you need the speed and versatility of a CNC router or the precision and durability of a CNC mill, understanding the strengths and weaknesses of each will guide you to the best decision for your projects.

FAQs

Finally, to address some of the most common questions and concerns about CNC routers and mills, we’ve compiled a list of frequently asked questions. These FAQs are designed to provide quick, clear answers to help you make a more informed decision.

Can a CNC router cut metal?

Yes, CNC routers can cut softer metals like aluminum, but they are not ideal for harder metals, which require the precision of a CNC mill.

What is the difference between a CNC router and a CNC mill?

The main difference lies in their precision and material handling. CNC routers are faster and more versatile, suitable for softer materials, while CNC mills offer greater precision and are designed for harder materials.

Which is more cost-effective: a CNC router or a CNC mill?

CNC routers are generally cheaper upfront, but CNC mills may offer better long-term value for projects requiring high precision and durable machine parts.

What industries use CNC mills?

CNC mills are widely used in industries like aerospace, automotive, and medical device manufacturing, where precision and material durability are paramount.