Drilling machines are the unsung heroes of manufacturing and construction, transforming raw materials into precisely engineered components with ease. Whether you’re working on a DIY project at home or managing a high-volume production line, understanding “what is drilling machines” can significantly enhance your efficiency and results.

What is a Drilling Machine? A drilling machine is a versatile tool used to create holes in various materials, including metal, wood, and plastic. It operates by rotating a drill bit to cut through the material. Common types include portable drills for DIY projects, bench drills for precision tasks, and CNC machines for automated production. Drilling machines vary in size, power, and application, making them essential in industries ranging from manufacturing to construction.

This guide delves into the types of drilling machines, their operation, and how to select the right one for your needs. We’ll also explore their historical development, helping you appreciate the evolution of this essential tool.

What is a Drilling Machine?

Drilling machines are essential tools designed to create precise holes in various materials. These machines are vital in numerous industries, from manufacturing and construction to home improvement. They come in a range of types and sizes, each suited for different applications and materials.

Historical Background

The evolution of drilling machines has been a fascinating journey. The earliest drilling devices, used in ancient times, were hand-powered tools designed for creating holes in wood and stone. By the late 1800s, the industrial revolution brought significant advancements, introducing steam-powered drill presses. The early 20th century saw the advent of electric drills, which revolutionized the industry with increased convenience and efficiency. The late 20th century further transformed drilling with the introduction of Computer Numerical Control (CNC) technology, which automated and refined drilling processes, leading to higher precision and productivity.

How Drilling Machines Work

Working Principle

Drilling machines operate on a simple yet effective principle: a rotating drill bit creates holes in a material. The motor drives a spindle that rotates the bit, while the workpiece is either held steady or moved on an adjustable table.

Components and Their Functions

Understanding the components of a drilling machine helps in comprehending its operation:

- Base and Column: The base provides stability, while the column supports the drill head and allows for vertical movement.

- Drill Head and Spindle: The drill head houses the spindle, which rotates the drill bit to cut through the material.

- Table: The table holds the workpiece and can be adjusted for different drilling angles and depths.

- Motor: Powers the spindle and controls the speed of the drill bit.

- Chuck: Holds the drill bit securely and allows for quick changes between bits.

Diagram of a Drilling Machine

Visualizing a drilling machine involves imagining a robust base with a vertical column extending upwards. At the top of the column, the drill head connects to the spindle. Below the drill head, the workpiece rests on a table, ready for drilling.

Types of Drilling Machines

Selecting the right type of drilling machine involves understanding the various options available. Each type has unique features and applications, tailored to specific needs and tasks.

Portable Drilling Machines

- Characteristics: These machines are lightweight and versatile, making them ideal for on-the-go tasks. They can be powered by electricity or batteries and offer adjustable speed settings.

- Uses: Perfect for DIY projects and light drilling in materials such as wood and plastic.

- Price Range: Typically ranges from $50 to $300, making them an affordable choice for casual users.

- Materials: Constructed from durable plastic and metal alloys.

Bench Drilling Machines

- Characteristics: Mounted on a bench, these machines offer stability and precision. They come with adjustable speed and depth controls.

- Uses: Suitable for precise drilling tasks in metal, wood, and plastic, commonly used in workshops.

- Price Range: Mid-range, from $200 to $800.

- Materials: Usually made from cast iron or steel.

Radial Drilling Machines

- Characteristics: Equipped with a radial arm for horizontal and vertical movement, allowing for flexibility and heavy-duty applications.

- Uses: Ideal for large or irregularly shaped workpieces and industrial drilling tasks.

- Price Range: Higher end, generally between $1,000 and $5,000.

- Materials: Built from heavy-duty cast iron and steel.

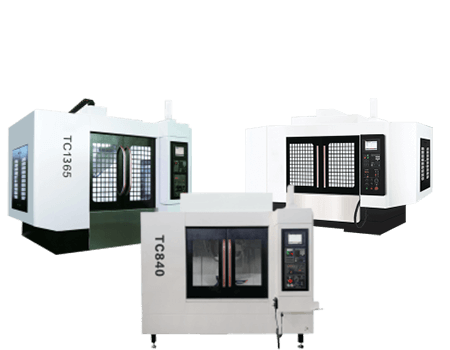

CNC Drilling Machines

- Characteristics: These machines are computer-controlled, offering automation and high precision for complex tasks.

- Uses: Best for high-volume production and intricate drilling, widely used in sectors like automotive and aerospace.

- Price Range: High investment, ranging from $10,000 to over $100,000.

- Materials: Constructed from advanced alloys and precision metals.

Deep Hole Drilling Machines

- Characteristics: Designed for drilling deep, precise holes with built-in coolant systems to manage heat.

- Uses: Essential for deep drilling in aerospace and heavy machinery.

- Price Range: Varies, typically from $5,000 to $50,000 or more.

- Materials: Made with specialized materials for extreme conditions.

Micro Drilling Machines

- Characteristics: Focuses on small and precise drilling tasks, featuring high-speed spindles.

- Uses: Ideal for electronics, medical devices, and small, intricate components.

- Price Range: Varies significantly, typically from $2,000 to $30,000 depending on features.

- Materials: Constructed with high-precision materials for accuracy.

How to Choose the Right Drilling Machine

Choosing the right drilling machine involves assessing your needs and comparing different features. Here’s how to make an informed decision:

Understanding Your Needs

Evaluate the specific requirements of your tasks, including the type of material, size of the workpiece, and precision needed.

Key Features to Consider

Look for features such as power, speed settings, and precision that match your application needs.

Budget Considerations

Set a budget and find a machine that offers the best value while meeting your feature requirements.

Brand and Warranty

Opt for reputable brands and check warranty options to ensure reliability and support.

User Reviews and Recommendations

Read reviews and seek recommendations to gauge the performance and reliability of different models.

Proper Use of Drilling Machines

To ensure precision and longevity, proper usage of drilling machines is essential. Follow these guidelines to achieve optimal results:

How to Use a Drilling Machine Correctly

Set up the machine according to the manufacturer’s instructions. Adjust speed settings and align the workpiece properly before starting.

Maintenance and Safety Tips

Regularly clean and maintain the machine. Follow safety guidelines to prevent accidents and ensure smooth operation.

Troubleshooting Common Problems

Address issues such as drill bit jams or motor malfunctions by referring to the user manual or consulting a professional.

Applications of Drilling Machines

Drilling machines are versatile tools used across various fields. Here’s how they are applied in different industries:

- In Manufacturing

Drilling machines are used for creating precise holes in metal, wood, and plastic, which is crucial for production lines.

- In Construction

They are employed for tasks like drilling holes in concrete and installing fixtures, making them essential for construction projects.

- In DIY and Home Workshops

For home improvement enthusiasts, drilling machines facilitate a range of projects, from assembling furniture to custom designs.

Future Trends in Drilling Machines

The drilling machine industry is evolving with advancements in technology and sustainability. Here’s what to expect in the future:

Automation and CNC Integration

Automation and CNC technology are enhancing precision and efficiency, shaping the future of drilling machines.

Sustainable and Energy-Efficient Machines

The focus is shifting towards energy-efficient machines that have a reduced environmental impact.

Smart Technology Integration

The integration of smart technologies and IoT is making drilling machines more advanced, with features like remote monitoring and diagnostics.

Conclusion

Drilling machines are crucial tools that play a significant role in various industries. Understanding their types, applications, and how to choose and use them properly can enhance your projects and ensure successful outcomes.

Ready to find the perfect drilling machine? Explore options and make an informed decision to enhance your drilling projects.

FAQs (Frequently Asked Questions)

What is the best drilling machine for beginners?

For beginners, a portable drill is ideal. It’s user-friendly, affordable, and versatile enough for a variety of home projects. Look for a model with adjustable speed settings and a comfortable grip.

How do I maintain a drilling machine?

Regular maintenance includes cleaning the drill bit and machine, checking for wear and tear, lubricating moving parts, and ensuring the machine is properly aligned. Always follow the manufacturer’s maintenance guidelines.

What are the common mistakes to avoid when using a drilling machine?

Avoid common mistakes such as using the wrong drill bit for the material, applying excessive pressure, or failing to secure the workpiece properly. Always use the correct speed and follow safety protocols.