Cast iron, steel, composite materials, and granite perform differently in various applications. Besides explaining their distinct properties, this text focuses on material cost and balancing performance with expenses. By comparing these materials, readers can better understand how to choose the right lathe bed material based on specific machining needs to achieve optimal performance and cost-effectiveness.

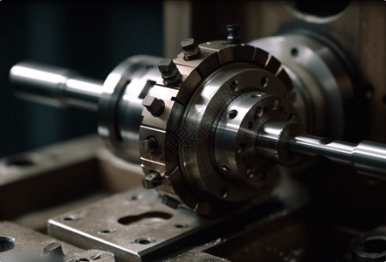

The lathe bed is a crucial component of the lathe. Its material choice directly impacts the machine’s performance, accuracy, durability, and cost. Each material has strengths and weaknesses in terms of rigidity, vibration absorption, wear resistance, and temperature adaptability. Selecting the right material for the lathe bed is essential for different application scenarios.

Common lathe bed materials and their impact on lathe performance:

Cast Iron:

Cast iron is a traditional and widely used material for lathe beds, especially in medium and large lathes. It offers high rigidity and excellent vibration absorption.

Advantages:

- High rigidity: The strength of cast iron prevents the lathe bed from deforming under heavy loads, providing a stable machining platform.

- Excellent vibration damping: Cast iron effectively absorbs vibrations generated during machining, reducing their impact on precision.

- High wear resistance: Cast iron has strong wear resistance, making it suitable for long-term, high-precision machining.

Disadvantages:

- Heavy weight: Cast iron beds are typically heavy, making them difficult to move or adjust, which may increase transportation and installation costs.

- Brittleness: Despite its high rigidity, cast iron is brittle and prone to cracking or breaking under extreme stress.

Steel:

Steel is also commonly used for lathe beds, especially in applications requiring higher strength and toughness. Steel beds offer greater strength and impact resistance than cast iron, but their vibration damping is slightly weaker.

Advantages:

- High strength and toughness: Steel beds have excellent strength and toughness, handling greater mechanical stress.

- Lighter weight: Compared to cast iron, steel beds are lighter, making transport and installation easier.

- Impact resistance: Steel resists damage under impact loads and offers high fracture resistance.

Disadvantages:

Poor vibration damping: Steel absorbs vibrations less effectively than cast iron, easily transferring them to the workpiece and affecting machining precision.

Composite Materials:

In recent years, composite materials (such as resin-based composites) have increasingly been used in high-precision lathe beds. These materials offer several advantages, especially in vibration absorption and weight control.

Advantages:

- Excellent vibration damping: Composites have outstanding vibration absorption, minimizing its impact on machining precision.

- Lightweight: Composites are lighter than metal, making equipment easier to move and adjust.

- Corrosion resistance: Composites offer great resistance to corrosion, suitable for harsh environments.

Disadvantages:

- Limited load capacity: Although composites excel in vibration damping, their load capacity is lower than steel or cast iron, making them less suitable for heavy-duty machining.

Granite:

In recent years, composite materials (such as resin-based composites) have been increasingly used in high-precision lathe beds. These materials offer multiple advantages, excelling in vibration absorption and weight control.

Advantages:

- Superior vibration absorption: Granite absorbs nearly all vibrations, providing extremely high machining precision.

- Strong temperature stability: Granite is resistant to environmental temperature changes, ensuring machine stability under various conditions.

Disadvantages:

- Very heavy: Granite beds are extremely heavy, making equipment transport and installation difficult.

When choosing lathe bed materials, price is a key consideration alongside performance. The cost of different materials directly affects the manufacturing cost, market pricing, and long-term maintenance expenses of the lathe.

Price analysis of lathe bed materials:

Cast Iron:

- Moderate price: Cast iron is a traditional lathe bed material, widely used in medium to large lathes. The material cost is relatively moderate, and manufacturing costs are manageable, making cast iron common in mid-to-high-end markets.

- High cost-effectiveness: Cast iron offers high rigidity, excellent vibration damping, and wear resistance, making it ideal for high-precision and long-lasting equipment, especially in mass production.

- Drawback: Despite its moderate price, cast iron is heavy, increasing transport and installation costs, especially for large equipment.

Steel:

- Higher price: Steel is generally more expensive than cast iron, especially high-quality steel. Its superior rigidity and toughness, particularly in load-bearing and impact resistance, make it ideal for high-strength applications, though the higher price limits it to specific demanding fields.

- Higher manufacturing cost: Steel beds are more costly and difficult to process than cast iron due to the complexity of cutting and forming steel. Although lighter than cast iron, steel beds are still heavy, leading to significant transport and installation costs.

Composite Materials:

- Higher cost: The manufacturing cost of composites is usually much higher than traditional metals. The complex production process, especially for resin-based composites, requires specific technology and equipment, raising the overall cost.

- High-end applications: The high cost limits composites to high-end precision machining tools. These machines are expensive but benefit from composites’ excellent vibration damping and lightweight properties, improving precision and reducing wear during long-term operation.

- Long-term cost advantage: Despite the high initial manufacturing cost, composites offer corrosion resistance and lightweight benefits, reducing long-term maintenance costs, especially in high-frequency production environments.

Granite:

- Highest cost: Granite is the most expensive lathe bed material. Its extraction, cutting, and finishing processes are highly complex, making it costly and reserved for ultra-high precision equipment.

- High initial cost: The purchase and installation costs of granite beds are very high, typically used in scientific research, aerospace, and high-precision industries. While it offers excellent vibration damping and temperature stability, its high price limits its use in most production environments.

- Low maintenance cost: Once installed, granite beds require relatively low maintenance and have a long lifespan, maintaining stability for years of high-precision machining. However, their significant weight leads to high transport and installation costs.

Balancing Price and Application Scenarios

When choosing lathe bed materials, the price typically needs to be balanced with specific application scenarios, machining requirements, and the expected lifespan of the equipment.

- Economic choice: If cost control is needed without sacrificing performance, cast iron is usually the best option. It offers good value in most machining scenarios with relatively low manufacturing and maintenance costs.

- High-strength demands: For applications that require heavy loads or high impact resistance, steel is a strong choice. Though more expensive than cast iron, its superior strength and toughness make it irreplaceable for certain machining needs.

- Precision and high-end needs: Composites and granite, despite their high cost, provide excellent vibration damping and precision, making them ideal for high-end precision machining. While the initial cost is high, they offer long-term benefits in specific industries.

Conclusion:

The choice of lathe bed material affects both machining performance and overall equipment cost. It’s important to balance performance with cost and usage needs. For general industrial production, cast iron and steel remain popular, offering good value for money. In high-end precision machining, where stability is critical, composites and granite, though expensive, offer undeniable long-term benefits.