In today’s fast-paced manufacturing world, precision and efficiency are paramount. Whether you’re a hobbyist, an engineer, or a small business owner, the ability to create intricate designs and components with ease is invaluable. Enter the CNC (Computer Numerical Control) machine—a game-changer in the realm of fabrication. While purchasing a commercial CNC machine can be a significant investment, building your own offers a cost-effective and customizable alternative.

Imagine having the power to design, build, and control your own CNC machine, tailored precisely to your needs. This comprehensive guide will walk you through every step of the process, from selecting the right components to the final calibration, empowering you to take full control of your manufacturing capabilities.

What is a CNC Machine?

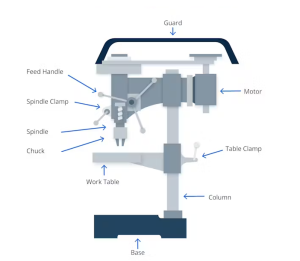

A CNC (Computer Numerical Control) machine is an advanced manufacturing device that uses computer software to automate the process of cutting, drilling, and shaping materials with high precision. CNC machines are integral to many industries, including automotive, aerospace, and woodworking, for producing intricate parts and components with minimal manual intervention. By interpreting digital designs, CNC machines can execute complex operations with consistency and efficiency.

Benefits of Building Your Own CNC Machine

Building your own CNC machine can be a very rewarding project. It has many benefits, such as saving money over buying a commercial machine, being able to customize the machine to your exact needs, and the satisfaction of learning how to build something with your own hands. You can design and build a CNC machine that fits your specific needs and requirements, whether it is for personal or business use. Plus, you will learn a lot about mechanical engineering, electronics, and software along the way.

Building a CNC machine yourself offers several advantages:

- Cost Efficiency: Significantly lower cost compared to purchasing a commercial machine.

- Customization: Tailor the machine to specific needs and applications.

- Educational Value: Gain hands-on experience in mechanical engineering, electronics, and software integration.

Overview of the Building Process

The process of building a CNC machine involves several critical steps. These include selecting the appropriate type of CNC machine, gathering and preparing materials and tools, designing the machine, assembling the components, installing necessary software, and conducting thorough testing and calibration. Each phase is crucial for ensuring that the final machine operates efficiently and meets performance standards.

The process involves:

- Selecting the Machine Type: CNC routers, mills, or laser cutters.

- Gathering Materials and Tools: Required components and tools.

- Designing the Machine: Create detailed plans and 3D models.

- Assembling Components: Build the frame, install motors, and wire electronics.

- Installing Software: Set up control software and firmware.

- Testing and Calibration: Ensure the machine operates correctly through rigorous testing.

Choosing the Right CNC Machine Type

CNC Router

A CNC router is a versatile machine ideal for cutting and shaping materials like wood, plastics, and soft metals. It is particularly well-suited for tasks such as sign making, cabinetry, and prototyping. CNC routers feature a spindle that moves along multiple axes to perform precise cuts and engravings, making them a popular choice for intricate and detailed work.

Applications: Ideal for woodworking, plastic cutting, and sign making.

- Working Area: 24” x 24” (varies by model)

- Accuracy: ±0.01 mm

- Spindle Speed: Up to 24,000 RPM

CNC Mill

CNC mills are designed for machining metal and other hard materials. These machines use a rotating cutter to remove material from a workpiece, creating complex shapes and precise dimensions. CNC mills are essential in industries such as metalworking, aerospace, and automotive, where high accuracy and robust construction are required.

Applications: Suitable for metalworking, precision parts, and complex machining tasks.

- Working Area: 30” x 15” x 15”

- Accuracy: ±0.005 mm

- Spindle Speed: Up to 10,000 RPM

CNC Laser Cutter

A CNC laser cutter employs a focused laser beam to cut or engrave materials like wood, acrylic, and metal. This type of CNC machine offers exceptional precision and is ideal for detailed designs. Laser cutters are frequently used in signage, custom fabrication, and craft industries, providing a clean and accurate cutting process.

Applications: For cutting and engraving materials such as acrylic, wood, and metal.

- Laser Power: 40W to 150W

- Accuracy: ±0.1 mm

- Cutting Speed: Up to 600 mm/s

Factors to Consider in Choosing

When choosing a CNC machine, you need to think about things like what materials you want to work with, how accurate you need the machine to be, how big of a workspace you need, and how much money you want to spend. Each type of CNC machine has its own advantages and limitations, so you need to pick the one that is right for you.

Materials and Tools Required

Frame Materials

The frame of a CNC machine provides structural support and stability. Common frame materials include aluminum and steel.

Aluminum: Lightweight and easy to machine.

Steel: Offers greater rigidity and durability.

- Example Dimensions: 8020 Aluminum Extrusions (20mm x 20mm)

Choose a material based on the machine’s intended use, size, and weight capacity.

Motors and Drivers

Motors are what make your CNC machine move. There are two main types of motors used in CNC machines: stepper motors and servo motors. Stepper motors are cheaper and give you good control over your machine, while servo motors are more expensive and give you better performance and accuracy. Drivers are what control the motors, so it is important to choose the right ones for your machine to make sure everything runs smoothly.

- Example: NEMA 23 Stepper Motor with 2.8 Nm Torque

- Servo Motors: For higher performance and accuracy.

- Example: AC Servo Motor with 1.5 Nm Torque

Linear Rails and Guides

Linear rails and guides ensure smooth and accurate movement of the machine’s moving parts. They provide support and reduce friction, which is essential for precise positioning. Investing in high-quality rails and guides can significantly enhance the machine’s performance and durability.

- Example: HIWIN Linear Rails.

- Bearings: Reduce friction and support moving parts.

- Example: SKF Linear Ball Bearings

Electronics

The electronics for your CNC machine include the controller, power supply, and various sensors. The controller takes commands from your computer and tells the motors and other components what to do. The power supply makes sure everything has the power it needs to work properly. The sensors give you feedback on where things are and how well your machine is performing.

- Example: Arduino Uno with GRBL Shield

- Example: 24V DC Power Supply

Miscellaneous Tools

In addition to the main components, you will need a variety of tools to help you put everything together and get your machine working. These include things like wrenches, screwdrivers, a soldering iron, and measuring tools. You will need these tools to assemble the components, make electrical connections, and make sure everything is the right size as you build your machine.

- Wrenches: For assembly.

- Screwdrivers: For securing components.

- Soldering Iron: For electrical connections.

Designing Your CNC Machine

Software for Design

When designing a CNC machine, you’ll need to create detailed blueprints and 3D models. Software tools such as Fusion 360, SketchUp, and SolidWorks are great for this. They allow you to see what the machine will look like, simulate its movement, and catch any problems before you start building.

Fusion 360: Comprehensive design and simulation tool.

SketchUp: User-friendly 3D modeling software.

SolidWorks: Professional CAD software for detailed designs.

Creating Detailed Blueprints

You’ll need detailed blueprints to guide you through the assembly process. These should include measurements, materials, and instructions for how to put everything together. Good blueprints will help you make sure everything fits together and the machine works the way it’s supposed to. This will save you from making mistakes and make the assembly process go smoother.

Blueprint Example: Detailed blueprints should include:

- Dimensions: Accurate measurements for each component.

- Assembly Instructions: Step-by-step guidance.

Considerations for Machine Size and Workspace

When you design your CNC machine, you need to think about how big it’s going to be and how much space you have. You need to make sure the machine will fit in your workspace and that you can work with the materials you want to use. You should also think about any upgrades or changes you might want to make in the future to make sure your design is flexible.

- Example: For a 24” x 24” working area, a workspace of at least 36” x 36” is recommended.

Assembly Process

Building the Frame

1.Assemble aluminum extrusions or steel parts as per blueprint.

2.Ensure all joints are secure and the frame is level.

A well-constructed frame is critical for achieving accurate and consistent machining results.

Installing Linear Guides and Bearings

- Install the linear guides and bearings onto the frame.

- Proper alignment is essential to ensure smooth movement of the machine’s moving parts.

- Carefully follow the design specifications to achieve the best performance and prevent mechanical issues.

Mounting Motors and Drives

Attach the motors and drives to the frame. Make sure they’re secure and lined up correctly. Connect the motors to the linear guides and other moving parts. You need to make sure everything is lined up correctly so the machine can move smoothly and accurately.

- Secure motors in place.

- Connect drives and ensure alignment with linear guides.

Wiring the Electronics

Connect the electronics, including the controller, power supply, and sensors.

Follow the wiring diagrams provided with the components to ensure correct connections. Proper wiring is crucial for reliable operation and preventing electrical issues.

Integrating the Controller

Install and set up the CNC controller. Connect it to the motors, sensors, and other electronic components. The controller takes the commands from your computer and tells the machine what to do.

Ensure that all connections are secure and that the controller is properly calibrated.

Software and Firmware

Choosing the Right CNC Control Software

Select a CNC control software that is compatible with your machine’s controller and meets your specific needs. Popular options include Mach3, LinuxCNC, and GRBL. The software allows you to create and manage machining programs and control the machine’s operation.

Options:

- Mach3: Widely used for Windows systems.

- LinuxCNC: Open-source software for Linux.

- GRBL: Firmware for Arduino-based controllers.

Installing and Configuring Software

Put the CNC control software on your computer and set it up to talk to your machine’s controller. Follow the instructions that come with the software to make sure you do everything right.

Set up things like motor settings, cutting speeds, and tool offsets to get the best performance.

Firmware Options for Controllers

Firmware controls the behavior of the CNC controller. Choose firmware that is compatible with your controller and supports the necessary features. Common firmware options include GRBL, Smoothieware, and Marlin. Ensure that the firmware is correctly installed and configured to achieve the best performance.

Options:

- GRBL: For simple setups with Arduino.

- Smoothieware: Advanced firmware for Smoothieboard setups.

Testing and Calibration

Initial Power-Up and Safety Checks

Before you start running your machine, do some initial power-up and safety checks. Make sure all your components work and you don’t have any loose connections. Look for any mechanical problems or signs of wear that could cause problems later.

Calibration of Movement and Precision

Calibrate your machine so it moves and cuts accurately. Test the machine’s movement in all directions and adjust things as needed. Try cutting some test pieces to make sure the machine does what you want it to do and make any adjustments you need to make it more accurate.

Testing Different Materials and Cutting Techniques

Try your machine out on different materials and with different cutting techniques to see how it performs. Adjust things like cutting speeds, feeds, and tool paths to get the best results. Watch how your machine works and make any changes you need to make your cuts better and more accurate.

Common Issues and Troubleshooting

Addressing Common Assembly Problems

Common assembly problems include things like parts not lining up, loose connections, and mechanical problems. Make sure everything is lined up and all your connections are tight to keep these problems from happening. Fix any problems you find right away so they don’t cause bigger problems later on.

Problems:

- Misalignment: Check and adjust component alignment.

- Loose Connections: Tighten all connections and ensure stability.

Solving Software and Firmware Issues

Software and firmware problems can mess up how your machine works. Some common problems are things like communication errors, wrong settings, and software crashes. Fix these problems by checking your connections, looking at your settings, and updating your firmware if you need to.

Problems:

- Communication Errors: Verify cables and connections.

- Incorrect Settings: Review and adjust software settings.

Maintenance Tips for Longevity

Regular maintenance is essential for the longevity of your CNC machine.

Tips:

- Regular Cleaning: Remove debris and dust.

- Lubrication: Apply lubricant to moving parts.

- Calibration Checks: Regularly check to maintain accuracy.

Additional Tips and Best Practices

Improving Machine Accuracy

To make your machine more accurate, make sure everything is lined up, use good linear guides and bearings, and keep everything clean. Minimize vibrations and keep your workspace clean to get better accuracy and performance.

Upgrading Components for Better Performance

Think about upgrading things like motors, drives, and electronics to make your machine work better. Upgrades can make your machine faster, more accurate, and do more things. Look at what’s available and pick things that will work with your machine.

Safety Considerations

Safety is important when you’re running a CNC machine. Wear safety glasses and hearing protection. Follow the safety guidelines for running the machine and working with materials. Look for any safety problems with your machine and fix them.

Conclusion

Building your own CNC machine is a fun project that can save you money, let you make things the way you want, and help you learn. By following the steps in this guide, you can build a CNC machine that works for you and does what you want it to do. Start building your CNC machine today and enjoy having your own precision machine.