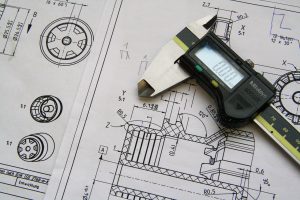

When it comes to precision machining, knee mills have been the backbone of the industry for decades. Whether you’re a seasoned machinist or just starting, understanding what a knee mill is, how it works, and why it remains relevant is crucial.

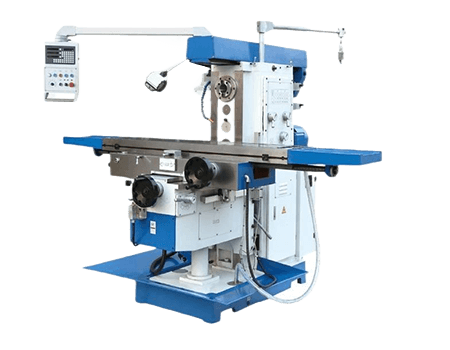

A knee mill is a type of vertical milling machine where the table moves up and down on the knee. This design allows the machine to handle a variety of operations, including drilling, boring, and cutting, with exceptional precision and flexibility. The knee milling machine’s adaptability makes it ideal for small to medium-sized machine shops and for tasks requiring intricate, detailed work.

Knee mills, with their unique design and unmatched versatility, stand out in a market flooded with various milling machines. But what exactly sets them apart? And more importantly, is a knee milling machine the right investment for you?

What is a Knee Mill

Knee mills have long been the workhorses of the machining world. Their design, which features a vertically adjustable table and a fixed spindle, offers machinists the ability to perform a wide range of tasks with a single machine. Whether you’re working on a small project or handling complex industrial jobs, a knee milling machine provides the flexibility and precision you need.

How Does a Knee Mill Work?

The basic operation of a knee milling machine revolves around its key components: the knee, saddle, table, spindle, and quill. Here’s how these components work together to perform precise machining tasks.

Historical Background of Knee Mills

To fully appreciate the value of knee mills in today’s machining industry, it’s essential to understand their historical context. Knee mills didn’t just appear out of nowhere; they are the result of decades of technological advancement and innovation. The evolution of knee milling machines is closely tied to the broader history of milling machines as a whole, which has seen significant changes over the last century.

Evolution of Milling Machines

The knee milling machine traces its origins back to the early 20th century when milling technology began to evolve rapidly. Before the knee mill, machinists relied on horizontal milling machines, which were less versatile and more challenging to operate. The introduction of the knee mill, with its vertical spindle and movable table, revolutionized the industry by offering greater control and precision.

Impact on the Machining Industry

As knee mills became more prevalent, their impact on the machining industry was profound. These machines quickly became the standard for precision machining, thanks to their versatility and ease of use. By the mid-20th century, companies like Bridgeport had made knee mills a household name in the industry. Their ability to handle diverse tasks made them indispensable in manufacturing and metalworking.

Knee Milling Machine Components

Understanding the components of a knee milling machine is crucial for anyone looking to get the most out of this versatile tool. Each part plays a specific role in the operation of the machine, contributing to its overall precision and functionality. Let’s dive into the key components that make up a knee mill and explore how they work together to create a powerful machining tool.

Knee

The “knee” in a knee milling machine refers to the vertically adjustable part of the machine. This component allows machinists to move the workpiece up and down, enabling precise control over the depth of cuts and the position of the workpiece relative to the spindle.

Saddle and Table

While the knee controls the vertical movement, the saddle and table are responsible for the horizontal positioning of the workpiece. These components allow the machinist to maneuver the workpiece in the X and Y axes, providing the necessary control for intricate operations. The table itself is where the workpiece is clamped, and it moves in tandem with the saddle for precise adjustments.

Spindle and Quill

The spindle is the heart of the knee milling machine, driving the cutting tool with power and precision. Connected to the motor, the spindle rotates at various speeds depending on the task at hand. The quill, which houses the spindle, allows for vertical adjustments, giving machinists the ability to control the depth of the cut. This combination of spindle and quill is what gives knee mills their reputation for versatility and precision.

Motor and Power Transmission

The power behind any knee milling machine comes from its motor, which is responsible for driving the spindle and, ultimately, the cutting tool. Modern knee mills are equipped with motors that range from 1 to 3 horsepower, providing ample power to cut through a variety of materials, from soft metals to hard alloys. The transmission system ensures that this power is delivered smoothly and efficiently, allowing the machine to perform a wide range of operations.

What is the difference between a bed mill and a knee mill?

Now that we’ve covered the essential components of a knee milling machine, it’s important to compare knee mills with another common type of milling machine: the bed mill. Understanding the differences between these two types of mills will help you determine which one is best suited for your needs.

What is Bed Mill

Bed mills are another type of vertical milling machine but with a key difference in their design. Unlike knee milling machines, where the table moves vertically along the knee, bed mills feature a fixed table. In a bed mill, it’s the spindle that moves up and down along the column, making it better suited for certain types of heavy-duty work.

Structural Differences

The most significant difference between knee mills and bed mills lies in their structure. Knee milling machines have a vertically adjustable table, making them more flexible for different types of work. In contrast, bed mills offer greater stability due to their fixed table, which is ideal for handling larger and heavier workpieces.

Operational Differences

Operationally, knee mills excel in tasks that require frequent adjustments and intricate details, thanks to their movable table. On the other hand, bed mills are preferred for operations involving larger, heavier workpieces that demand consistent power and stability. This makes bed mills more suitable for tasks where the workpiece remains stationary, and the tool does all the movement.

Advantages and Disadvantages of Each

Both knee and bed mills have their advantages and disadvantages depending on the application. Knee mills are highly versatile and ideal for detailed work, but they may not provide the same level of stability as bed mills for large projects. Conversely, bed mills are powerful and stable, but their fixed table design can limit flexibility in some operations.

Choosing the Right Milling Machine

Choosing between a knee milling machine and a bed mill largely depends on the specific needs of your project. If your work involves precision tasks with frequent adjustments, a knee mill might be your best bet. However, for heavy, consistent milling work, especially with larger pieces, a bed mill could be more suitable.

Types of Knee Milling Machines

With an understanding of the differences between knee and bed mills, it’s time to delve into the various types of knee milling machines available. The type of knee mill you choose will depend on factors such as your budget, the precision required, and the nature of the tasks you’ll be performing.

Manual Knee Mills

Manual knee milling machines are the traditional choice for machinists who prefer hands-on control. These machines allow the operator to make precise adjustments manually, which can be beneficial for custom or low-volume work.

- Price Range: $5,000 to $15,000

- Applications: Suitable for small to medium-sized operations, where the focus is on low-volume, high-precision work.

- Precision: Manual knee mills can achieve high precision with experienced operators, typically within ±0.001 inches.

CNC Knee Mills

CNC knee milling machines take the traditional knee mill design and integrate it with computer numerical control (CNC) technology. This combination allows for automated precision, making these machines perfect for high-volume production or tasks that require consistent accuracy.

- Price Range: $20,000 to $50,000

- Applications: Ideal for medium to large-scale production environments where accuracy and repeatability are critical.

- Precision: CNC knee mills offer precision within ±0.0001 inches, depending on the model and setup.

Hybrid Knee Mills

Hybrid knee milling machines offer a unique blend of manual and CNC capabilities. This flexibility allows operators to switch between manual control for custom work and CNC automation for repetitive tasks, making them incredibly versatile.

- Price Range: $15,000 to $40,000

- Applications: Suitable for shops that require flexibility, allowing operators to perform both custom, manual work and automated production runs.

- Precision: Hybrid knee mills maintain high precision, with CNC features ensuring tight tolerances while allowing manual adjustments when needed.

Applications of Knee Milling Machines

Having explored the types of knee milling machines, it’s essential to understand their applications in various industries. Knee mills are highly versatile machines that can be used in a wide range of settings, from small workshops to large-scale manufacturing plants.

Common Industries Using Knee Milling Machines

Knee milling machines are widely used across various industries, including automotive, aerospace, and metalworking. Their precision and versatility make them essential for producing complex parts and components.

Typical Workpieces and Operations

Knee milling machines are commonly used for tasks such as drilling, boring, cutting, and shaping metals. They excel in producing parts with tight tolerances and intricate details, which are crucial in industries like aerospace and automotive.

Advantages of Using Knee Milling Machines for Specific Applications

The primary advantage of using a knee milling machine is its ability to handle a wide range of materials and tasks with precision. Whether you’re machining a small component or a larger workpiece, a knee milling machine offers the control and accuracy needed for high-quality results.

Bridgeport Knee Mill: History and Current Status

One cannot discuss knee milling machines without mentioning the iconic Bridgeport knee

mill. This machine has become a symbol of quality and precision in the machining world, and its history is deeply intertwined with the evolution of knee mills in general.

The Birth of the Bridgeport Knee Mill

The Bridgeport knee mill was first introduced in 1938 and quickly became the gold standard for milling machines. Its innovative design, featuring a vertically adjustable table and a fixed spindle, set it apart from other milling machines of its time.

Features and Innovations

The Bridgeport knee milling machine introduced several innovations that have since become standard in the industry. These include a rotating turret head, which allows the spindle to be positioned at various angles, and a variable-speed motor that provides greater control over the cutting process.

The Legacy of Bridgeport

Even today, the Bridgeport knee milling machine remains synonymous with quality and reliability. Its design has been widely copied, but the original Bridgeport remains highly sought after by machinists who value its durability and precision.

Current Status

Today, Bridgeport knee milling machines are still in use around the world. While the brand has changed hands over the years, the legacy of the Bridgeport knee mill lives on, with new models being produced and old models being refurbished for continued use.

Advantages of Knee Milling Machines

Having reviewed the history and current status of the Bridgeport knee mill, it’s clear that knee milling machines have several advantages that make them indispensable tools in the machining industry. Whether you’re a seasoned professional or a beginner, these benefits are worth considering.

- Precision and Versatility

Knee milling machines are known for their precision, making them ideal for tasks that require intricate detail. The adjustable table allows for fine-tuning the position of the workpiece, ensuring that every cut is exactly where it needs to be.

- Flexibility in Machining

The ability to move the table in multiple directions gives knee milling machines a level of flexibility that other machines simply can’t match. This makes them suitable for a wide variety of tasks, from simple drilling to complex shaping.

- Cost-Effectiveness

Knee milling machines offer a cost-effective solution for small to medium-sized shops. They are generally less expensive than bed mills and can perform a wider range of tasks, making them a versatile addition to any workshop.

- Durability and Longevity

A well-maintained knee milling machine can last for decades. Their robust construction and quality materials ensure that these machines can withstand the rigors of daily use, providing reliable performance year after year.

Considerations Before Buying a Knee Milling Machine

If you’re considering adding a knee milling machine to your workshop, it’s essential to think through a few key factors before making a purchase. From assessing your specific needs to deciding whether to buy new or used, these considerations will help you make an informed decision.

Assessing Your Needs

Before investing in a knee milling machine, it’s crucial to assess your specific needs. Consider the types of materials you’ll be working with, the complexity of the tasks you’ll be performing, and the space available in your workshop.

New vs. Used Knee Milling Machines

When deciding whether to purchase a new or used knee milling machine, weigh the pros and cons. A new machine will come with a warranty and the latest features, but a used machine can be a more affordable option if it’s been well-maintained.

Key Features to Look For

When shopping for a knee milling machine, look for key features such as spindle speed, motor power, and table size. These factors will determine the machine’s capabilities and suitability for your specific tasks.

Budgeting and Financing Options

Knee mills vary widely in price, depending on their features and condition. Establish a budget before you start shopping, and consider financing options if needed. Investing in a quality knee mill can pay off in the long run, so it’s worth spending a little more to get a machine that will meet your needs.

Maintenance and Troubleshooting

After acquiring a knee milling machine, maintaining it in top condition is essential for ensuring its longevity and performance. Regular maintenance and troubleshooting can prevent costly repairs and downtime, keeping your workshop running smoothly.

Routine Maintenance Tasks

Routine maintenance is key to keeping your knee mill in top working condition. Regularly clean and lubricate moving parts, check for wear and tear, and make adjustments as needed to ensure smooth operation.

Common Issues and Solutions

Like any machine, knee mills can experience issues over time. Common problems include spindle wear, table misalignment, and motor issues. Regular maintenance can prevent many of these problems, but it’s also important to know how to troubleshoot and fix them when they occur.

Safety Considerations

Safety should always be a top priority when operating a knee milling machine. Make sure to wear appropriate protective gear, keep the work area clean and organized, and follow the manufacturer’s guidelines for safe operation.

Minnuo Knee Mills

If you’re in the market for a high-quality knee milling machine, look no further than Minnuo Machine. Our range of knee mills combines traditional craftsmanship with modern technology to deliver machines that meet the demands of today’s machinists. Whether you’re looking for a manual, CNC, or hybrid knee mill, we have the perfect machine to suit your needs.

Conclusion

Knee milling machines are versatile, precise tools essential for precision machining. Whether manual or CNC, they offer flexibility and durability, making them ideal for various industries. Investing in the right knee mill ensures long-term performance and exceptional results. Explore Minnuo Machine’s selection for quality, reliable options.

FAQs: People Also Ask

Can a knee milling machine handle CNC tasks?

Yes, many modern knee mills are equipped with CNC capabilities, allowing them to perform automated tasks with high precision. These CNC knee mills offer the best of both worlds, combining traditional milling with advanced automation.

How often should I maintain my knee milling machine?

Routine maintenance should be performed regularly, with daily cleaning, weekly lubrication, and monthly checks of all critical components. Proper maintenance can extend the life of your knee milling machine and ensure consistent performance.