When it comes to manufacturing, choosing the right machining method is crucial. Manual machining vs CNC machining are two common methods, each with its own pros and cons. Understanding the differences and characteristics of each can help you make an informed decision.

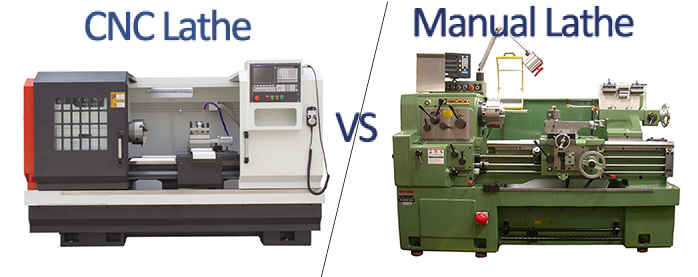

Manual Machining vs CNC Machining: manual machining relies on the skill and precision of the operator to control the cutting tools and machinery, suitable for low-volume production and custom work. In contrast, CNC (Computer Numerical Control) machining automates the process, ensuring high precision and repeatability, ideal for high-volume production and complex designs. It all depends on what you need.

Now, let’s get into the details of these two machining methods and their applications.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a method where computers control machine tools to perform machining tasks. It uses pre-programmed software to control the movement and speed of the tools, achieving high precision and efficiency.

Histories

CNC machining technology was born in the 1940s and was first used in the aerospace industry. With the development of computer technology, CNC machining has been widely used in various manufacturing fields, including automotive, electronics, and medical devices.

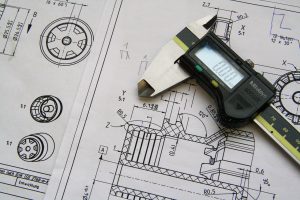

Technical Principles

CNC machining converts CAD (Computer-Aided Design) files into CAM (Computer-Aided Manufacturing) instructions to control the machine’s movements and operations. These instructions include cutting paths, feed rates, and tool selections.

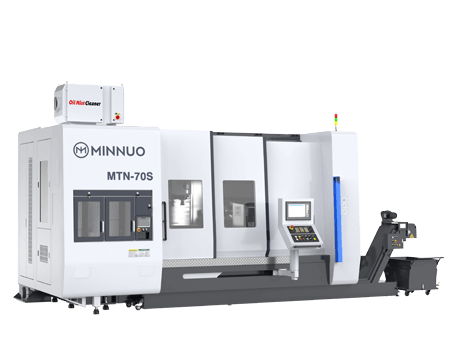

Common machines

Common CNC machines include CNC lathes, CNC milling machines, CNC drilling machines, and CNC grinders, each serving specific purposes and offering distinct advantages.

What is Manual Machining?

Manual machining refers to machinists operating machine tools manually to perform machining tasks. This traditional method relies on the skills and experience of the machinist, who manually adjusts tools and workpieces to achieve the desired results.

Histories

Manual machining dates back to the Industrial Revolution and is the foundation of modern manufacturing technology. Despite the development of automation, manual machining is still irreplaceable in certain fields.

Technical Principles

Manual machining relies on the machinist manually adjusting various parts of the machine, such as tools, workpiece positions, and cutting parameters, to complete the machining tasks.

Common machines

Common manual machining tools include manual lathes, manual milling machines, drill presses, and grinders. These machines have simple structures and flexible operations.

Advantages and Disadvantages of Manual Machining

Advantages

Cheap: Manual machines are cheap to buy, making them accessible to small businesses or individuals. They are also cheaper to maintain.

Flexible: Manual machining allows you to make changes on the fly, which is perfect for small runs and a variety of jobs. You can adjust the machining parameters as you go.

Skill Building: Manual machining helps you gain the experience and skills you need to become a great machinist.

Examples: Small shops or even one-man operations use manual machines to make custom parts. They can react quickly to their customers’ needs with manual machines and stay competitive.

Disadvantages

Slow: Manual machines are slow because you’re running them. You can’t make parts as fast as you can with a CNC machine. They are not good for production work.

Not as Accurate: Manual machining is not as accurate or consistent as machining with a CNC machine. You can make mistakes when you’re machining.

Hard on You: Manual machining is hard on you. It’s physically demanding and takes a lot of time. You can get tired.

Examples: You can see the limitations of manual machining when you try to make high-precision parts or large quantities of parts. For example, it’s hard to make aerospace parts with manual machines because you can’t hold the tight tolerances they require.

Advantages and Disadvantages of CNC Machining

Advantages

Accurate: CNC machines are very accurate and consistent because they are controlled by a computer. Every part you make is the same.

Fast: CNC machines can run all day long, making them great for production work. They are fast. You don’t have to do much.

Complex: CNC machines can do complex shapes and structures. They can do all kinds of machining. You can do three-dimensional machining with a multi-axis CNC machine.

Examples: CNC machining is used in high-end manufacturing like aerospace and medical devices. They use CNC machines because they need the accuracy and consistency.

Disadvantages

Expensive: CNC machines and maintenance are expensive. You have to spend a lot of money to buy a CNC machine and keep it running.

Programming: You have to know how to program and run a CNC machine. You have to go to school to learn how to do it. If you make a mistake in your program, you can ruin a part or break the machine.

Not Flexible: CNC machining is not flexible. You can’t make changes on the fly. If you want to change something, you have to change the program. It takes time.

Examples: When companies switch to CNC machining, they have to deal with the cost of the machines and the training. For example, small shops might not be able to afford a CNC machine, so they stick with manual machining.

Differences in Applications

Manual Machining Applications: Manual machining is often used for small quantities and simple parts, such as repair work and mold making. Custom and repair work often rely on manual machining.

CNC Machining Applications: CNC machining is ideal for mass production and complex parts, such as automotive components, aerospace parts, and medical devices. CNC machining allows for efficient, high-precision production.

Differences in Costs

Manual Machining Costs: Manual machines are less expensive, making them suitable for budget-conscious businesses or individuals. Maintenance costs are lower, making long-term use more economical.

CNC Machining Costs: CNC machines are expensive, but their efficiency and precision can lower per-piece costs in mass production. Despite the high initial investment, CNC machining significantly increases production efficiency and product quality in the long run.

Cost-Effectiveness Analysis: The cost-effectiveness of manual and CNC machining depends on the scale of production. Manual machining is more cost-effective for small quantities, while CNC machining is cost-effective for large-scale production.

Differences in Structure

Manual Machining Machines Structure: Manual machines are simple, easy to operate, and easy to maintain. Machinists can manually adjust machine parts to complete tasks.

CNC Machining Machines Structure: CNC machines are complex, with computer control systems and multi-axis mechanisms. They require professional maintenance, and operators need technical knowledge.

Differences in Materials

Manual Machining Materials: Manual machining can work with various materials, including metals, plastics, and wood. However, efficiency decreases with harder or more difficult-to-machine materials.

CNC Machining Materials: CNC machining can handle materials of varying hardness, making it suitable for high-precision and high-hardness material machining. CNC machines can process materials like titanium alloys, stainless steel, and aluminum alloys.

How to Choose?

Choosing between manual and CNC machining is an important decision that involves multiple considerations. Here’s a detailed guide to help you make an informed choice:

1. Understand Your Needs

First, clearly define your machining needs:

- Production Scale: For small-scale production, manual machining may be more cost-effective; for large-scale production, CNC machines are more suitable.

- Machining Complexity: For simple, repetitive tasks, manual machining is sufficient; for complex, varied parts, CNC machines provide higher precision and efficiency.

- Product Precision Requirements: High-precision products usually require CNC machines to ensure quality and consistency.

- Material Types: Different materials have different machining characteristics; choose equipment that suits the materials you commonly work with.

2. Budget Considerations

Budget plays a significant role in your choice of manual or CNC equipment. Consider not only the initial purchase cost but also long-term maintenance and operation expenses.

- Initial Cost: Manual machining equipment is cheaper, making it suitable for those with limited budgets; CNC machines require a significant initial investment but offer long-term benefits.

- Maintenance Cost: Manual machines have lower maintenance costs, while CNC machines require regular professional maintenance, resulting in higher costs.

- Operational Cost: Manual machining requires more human labor, increasing labor costs; CNC machining is highly automated, reducing labor costs but requiring skilled operators for programming and operation.

3. Technical Skill Level

Operating manual and CNC machines requires different skill sets.

Manual Machining: Requires machinists with extensive experience and manual adjustment skills.

CNC Machining: Requires operators with programming and computer skills, capable of using CAD/CAM software for design and machining.

4. Equipment Brand and Supplier

Choosing reliable brands and suppliers ensures equipment quality and after-sales service.

- Brand Reputation: Choose reputable, well-established brands with a proven track record of performance and stability.

- Supplier Services: Select suppliers that offer comprehensive after-sales services, including installation, training, and maintenance.

5. Equipment Features and Specifications

Choose equipment based on your specific needs.

- Machining Range: Select equipment that meets your maximum machining size and weight requirements.

- Precision and Speed: Choose equipment specifications based on the required machining precision and production efficiency.

- Versatility: Some machines offer multiple machining functions, increasing utilization and flexibility.

6. Future Expansion

Consider future growth and choose expandable equipment.

- Modular Design: Choose equipment with a modular design for easy future expansion and upgrades.

- Software Upgrades: CNC equipment with upgradable software ensures long-term suitability.

7. Environmental and Safety Considerations

Environmental and safety performance are important factors.

- Environmental Performance: Choose environmentally friendly, low-emission equipment that complies with regulations.

- Safety Performance: Ensure equipment has comprehensive safety features to protect operators.

Summary of the Selection Guide

When you’re choosing machining equipment, you need to look at all of these things together and combine your needs with your plans for growth. Both manual and CNC have their own strengths and applications. Picking the right one will help you make parts efficiently and cost-effectively.

Manual Machining vs CNC Machining: Which One is Right for You?

Summary of the Comparison: Look at the pros and cons and the situations where you would use each one to help you make a decision. Manual machining is good for small businesses or individuals on a budget. CNC machining is good for big companies that need to make a lot of parts and need to make them very accurately.

In Conclusion

Both manual and CNC machining have their own strengths and applications. Knowing what those are and how they’re different, and then matching that up with what you need to do, will help you pick the right way to make parts. If you have any questions or need any help, please let me know.

Frequently Asked Questions

Can manual machines replace CNC machines?

No. Manual machines are usually slower and less accurate, making it difficult to accomplish complex machining tasks.

Can CNC machines completely replace manual machines?

CNC machines can completely replace manual machines, regardless of cost, but given the advantages of manual machines, there is no way to completely replace them.