Milling machines and machining centers are two commonly used devices in the manufacturing industry. Many individuals often struggle to differentiate between milling machines and machining centers. This article aims to provide a detailed explanation of the differences between milling machines and machining centers, helping readers gain a clearer understanding of these essential manufacturing tools.

Definition

What is a Milling Machine?

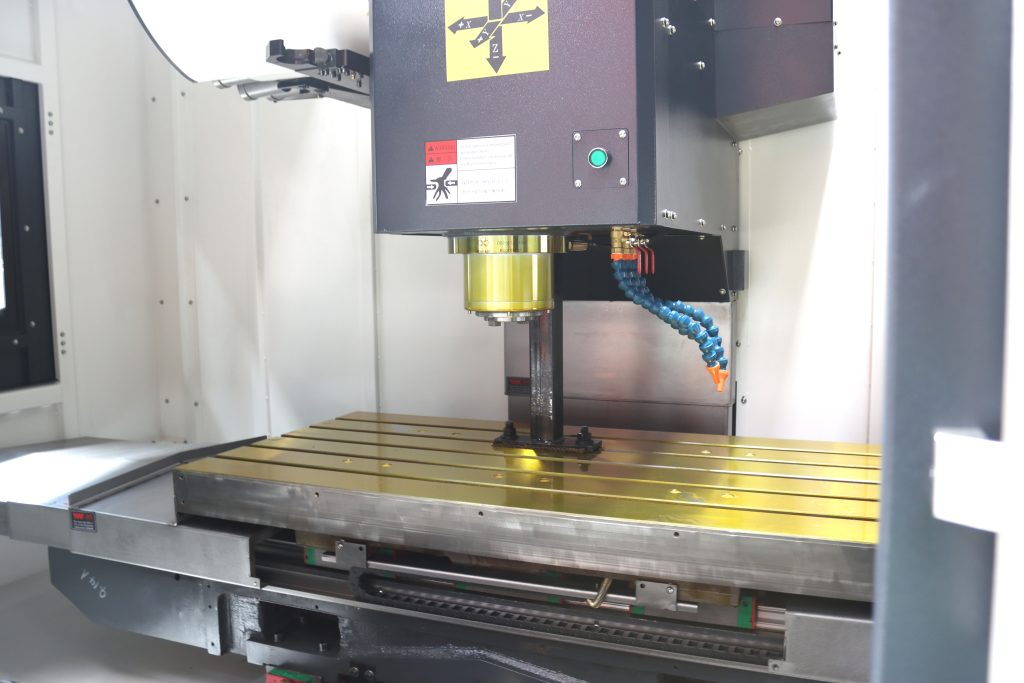

A milling machine is a machine where the workpiece is fixed and the cutting tool rotates to perform cutting operations. With various cutting tools, milling machines can be used to process a wide range of shapes including flat surfaces, curves, and grooves.

What is a Machining Center?

A machining center is a multifunctional CNC milling machine that combines milling, turning, boring, and other machining processes. Machining centers are highly automated, resulting in fast production rates and high precision in manufacturing products.

Differences between Milling Machines and Machining Centers

Many people consider machining centers to be an advanced version of CNC milling machines, and indeed they are. Machining centers have evolved from milling machines. Here is a comparison of the two.

In terms of Design:

1. Control Systems

Machining centers are equipped with a wider range of functionalities, which necessitates a more complex control system capable of handling automatic tool changes, automatic workpiece clamping, and other features. In contrast, milling machines have fewer functions compared to machining centers, resulting in simpler control systems.

2. Spindle Power

Typically, machining centers are equipped with high spindle power. The spindle power of a machining center generally ranges from tens of kilowatts to hundreds of kilowatts, while the spindle power of milling machines falls between several kilowatts and tens of kilowatts. Variations in spindle power also occur based on different types and brands.

3. Number of Axes

CNC milling machines typically have three or four axes. A three-axis setup includes the x, y, and z axes, while a four-axis setup adds a rotary axis to the three-axis system. Machining centers have at least three axes but generally have four or five-axis capability for expanded machining capabilities.

4. Size

Generally, machining centers have a larger footprint than milling machines. This is because machining centers handle a wider range of tasks and process complex, large workpieces, requiring more space.In comparison to machining centers, milling machines have a simpler range of functions. A basic manual milling machine may only have three axis structures. Additionally, their smaller size makes them easier to position within a workshop.

5. Whether it has a tool magazine?

The machining center is equipped with a tool magazine and an automatic tool changing system. The magazine features a robotic arm that can automatically swap out tools.

The tool magazine includes ball end mills, end mills, bull mills, and other tools to meet various product processing needs.Milling machines are divided into CNC milling machines and conventional milling machines. CNC milling machines are automated for processing by a computerized control system, while conventional milling machines are manually operated by an operator for processing.The level of automation in milling machines is not as high as that in machining centers,even CNC milling machines cannot achieve automatic tool changes.

6. Is it full protection?

Machining centers are fully enclosed for protection. Many older milling machines have semi-open protection devices, allowing metal debris and coolant to splash out during operation, posing health risks to operators and compromising both the safety and the working environment.Today’s CNC milling machines have improved protective devices, providing better safety measures.

7. Whether with automatic chip conveyor?

Older milling machines lack an automatic chip disposal system, whereas modern CNC milling machines and machining centers are equipped with automatic chip disposal systems.

The automatic chip disposal system can promptly clear away waste chips, ensuring a clean working environment, reducing manual intervention, extending tool life, and benefiting production processes.

In terms of Strengths:

1. Precision

The stable structural design, advanced control system, and transmission system of machining centers ensure precise machining. In contrast, CNC milling machines, with their simpler structural design, do not achieve the same level of precision as machining centers.

2. Speed

Compared to milling machines, machining centers have higher processing speeds. Machining centers feature a larger spindle speed and higher feed rates, whereas milling machines have lower spindle power and feed speeds.

3. Rigidity

Machining centers are known for their stable structure supported by a robust bed and pillar design, suitable for heavy cutting. In addition, they feature a powerful spindle with high resistance, providing exceptional rigidity. In contrast, milling machines have a simpler structure and cannot withstand cutting forces and speeds as effectively as machining centers.

4. Processing Range

The processing range of milling machines is not as extensive as that of machining centers. Milling machines are commonly used for simple flat or multi-sided machining, while machining centers are preferred for processing complex, large, three-dimensional parts and surfaces.Milling machines can perform milling operations and can be used to process flat surfaces, grooves, shallow holes, threads, and more. In addition to milling operations, machining centers can also perform boring, drilling, and other operations.

5. Automation Level

Machining centers are equipped with automatic tool changing systems, automatic clamping systems, and automatic measurement systems, eliminating the need for manual tool changes, workpiece clamping, and measurements by operators. This high level of automation in machining centers reduces manual intervention, aiding in continuous production and boosting productivity.

6. Safety

When machine equipment is in compliance, operators are properly protected, and operations are conducted according to procedures, both milling machines and machining centers exhibit high safety ratings.Milling machines involve more manual operation, requiring operators to change cutting tools and clamp workpieces during the process. In contrast, machining centers have a higher level of automation, eliminating the need for manual tool changes and workpiece clamping. Nevertheless, close monitoring of the operation process is still necessary to ensure the safe operation of the equipment. Additionally, safety devices and protective covers are in place to ensure operational safety.

Skills Training:

When operating CNC milling machines, operators need to understand programming, machine operations, safety protocols, and related content. Because machining centers have a higher level of automation, the skill requirements for operators are also elevated. Operators need to master more complex CNC programming and machine-related knowledge.

Applications:

CNC milling machines are highly versatile, suitable for small-batch production of simple-shaped, high-precision small parts such as aircraft components, automotive parts, and plastic molds.Machining centers are suitable for large-scale production of complex-shaped, high-precision large parts, including medical equipment, precision instruments, and automotive chassis.

Cost:

Machining centers with high automation levels require numerous automated components, leading to higher equipment costs.Due to the complexity of the equipment, both programming and machine operation require human labor and technical support, leading to increased operational and maintenance costs.On the contrary, milling machines have lower operating and maintenance costs. For large-scale production, machining centers offer fast production efficiency and lower costs. For small-scale and simple part production, choosing a milling machine can provide better value for your money.

Conclusion:

That’s all about the differences between milling machines and machining centers. If you’d like to learn more about milling machines and machining centers, please contact us. Thanks for reading!