From the moment humanity first laid hands on primitive tools, machining has been a kind of magical act of creation. Today, the mini lathe brings this ancient craft into the modern age, breathing new life into small workshops, home studios, and even classrooms. With a compact setup, you can easily cut, shape, and polish metal, wood, and even plastic. This small yet powerful machine puts endless possibilities right at your fingertips. Whether you’re carving a delicate model or crafting a practical everyday piece, the mini lathe becomes the perfect partner for transforming ideas into reality. It’s more than just a tool; it’s a personal workstation for dreams, a platform where anyone can unleash their creativity. So, let’s dive into the immense potential of this mini machine and see how it can bring the art of machining into your life.

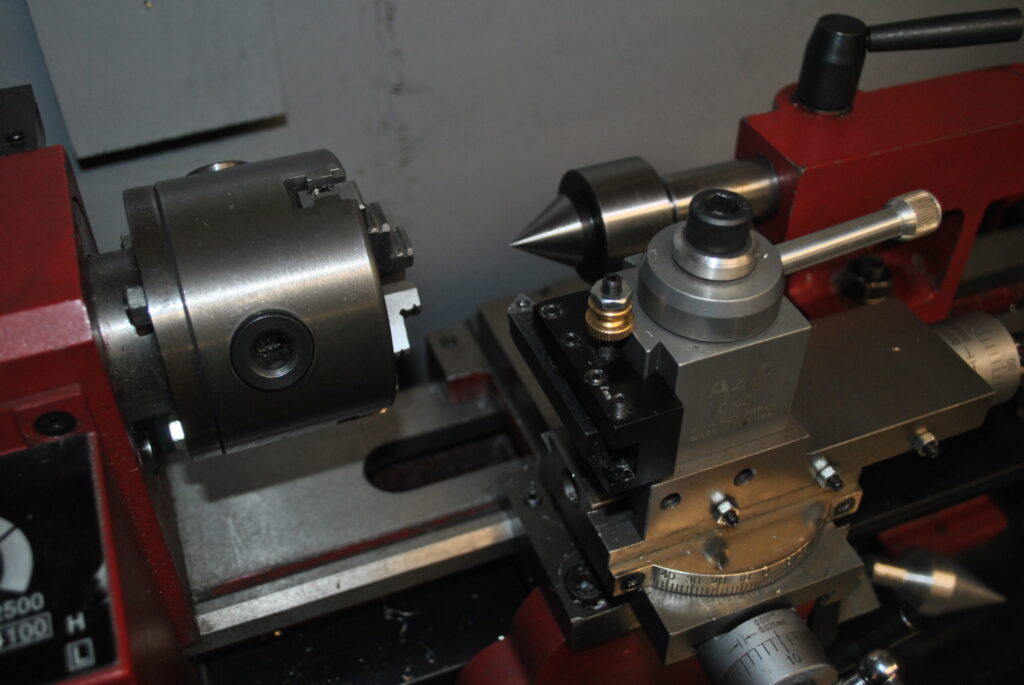

A mini lathe is a compact lathe machine, designed for ease of use and perfectly suited for crafting small parts. It’s commonly used for fine machining on materials like metal, wood, and plastic, and performs various standard turning tasks, including cutting, drilling, taper turning, and threading.

In this article, we’ll explore its types, functions, advantages, applications, and how to choose the right mini lathe for your needs.

What is a Mini Lathe?

A mini lathe is a scaled-down version of a traditional lathe, designed to be compact and easy to operate, making it perfect for machining small parts. It’s commonly used for precision work on materials like metal, wood, and plastic. Despite its smaller size, a mini lathe can handle a variety of standard turning tasks, including cutting, drilling, taper turning, and threading. A mini lathe works well not only in home workshops but also in small manufacturing setups and prototype projects.

Mini lathes come in different sizes and specifications, usually categorized by bed length and machining diameter. Smaller models are ideal for tiny part machining, while slightly larger ones can accommodate medium-sized workpieces.

Why Choose a Mini Lathe?

Mini lathes are widely popular for their flexibility and cost-effectiveness. Here are some key reasons why a mini lathe might be the right choice:

- Portability

Mini lathes are compact, small in size, and take up very little space, making them ideal for home workshops and small workspaces. They’re easy to move around and can be placed on a tabletop, making them incredibly convenient to use. - Ease of Use

Compared to larger industrial lathes, mini lathes are simpler to operate. They’re an excellent entry-level tool for beginners looking to get started in machining. Plus, many mini lathes come with detailed instructions, allowing even those new to the field to quickly get the hang of it. - Versatility

Despite their small size, mini lathes are capable of performing a variety of tasks, including turning, drilling, grooving, and threading. They’re well-suited for precision machining of small parts, making them perfect for model-making and DIY projects. - Cost-Effectiveness

Mini lathes are relatively affordable, making them a great choice for users on a budget. They not only save on initial investment but also have low maintenance costs, making them a practical and economical option for home users and small workshops. - Primary Applications of a Mini Lathe

Mini lathes find use in a wide range of fields, including:

- Model Making: Model enthusiasts rely on mini lathes to machine intricate parts for airplane, ship, and car models. With a mini lathe, they can achieve the high precision required for these detailed projects.

- Jewelry Making: In jewelry production, artisans use mini lathes to cut and engrave precious metals, crafting delicate rings, bracelets, and necklaces with intricate detail.

- Education and Training: Many schools and training centers include mini lathes in their curriculum to teach students basic lathe operations and machining principles. Their simple structure and ease of use make them ideal educational tools.

- Small Repairs: Mini lathes work well for small repair tasks, allowing users to fix parts, customize tools, and create specialized screws, making them perfect for minor restoration work.

How to Choose the Right Mini Lathe

With so many types of mini lathes available, selecting the right model is essential. Here are some key factors to consider:

- Work Range and Size

First, consider the bed length and maximum machining diameter of the mini lathe. Smaller lathes work well for tiny parts, while larger models handle medium-sized pieces. Choose the lathe size based on the usual dimensions and types of materials you plan to work with. - Spindle Speed and Horsepower

Different materials and machining tasks require various spindle speeds and power levels. For example, metal machining benefits from higher horsepower and lower speeds, while woodworking works best with higher speeds. A mini lathe with adjustable speed settings offers more flexibility for different projects. - Bed Material and Structure

The bed material of a mini lathe affects its stability and durability. Cast iron beds provide more stability and reduce vibration, though they tend to be heavier. Aluminum beds, on the other hand, are lighter and easier to move, making them suitable for home workshops. - Precision and Features

The precision of a mini lathe directly impacts the quality of your work. Choosing a lathe with high accuracy improves the detail of your machining. Additionally, some models include CNC capabilities, which are ideal for more complex and precise tasks.

Tips for Using a Mini Lathe

Whether you’re a beginner or an experienced user, these tips can help you get the most out of your mini lathe:

- Safety First: Always wear protective eyewear, and keep loose clothing and hair away from the machine. Make sure the lathe is stable, and avoid adjusting settings while it’s running.

- Choose the Right Tool: Select the right cutting tool based on the material. For metal machining, use carbide tools, while high-speed steel tools work well for wood.

- Regular Maintenance: Keep the machine clean, and lubricate the spindle and guideways regularly. This routine extends the lathe’s lifespan and enhances its performance. Check for worn-out parts and replace them as needed.

- Adjust Speed Properly: Set the spindle speed based on the material and machining requirements. Avoid using high speeds on hard materials and low speeds on softer ones. This helps prevent tool wear and minimizes workpiece deformation.

Future Trends of Mini Lathes

As CNC technology continues to advance, many mini lathes now come equipped with CNC control functions. This combination of automation and smart technology allows mini lathes to be useful not only for DIY projects but also for efficient and precise production in small manufacturing and design tasks. In the future, mini lathes are likely to find even broader applications across various fields, such as electronics and medical device part manufacturing.

Conclusion: The Endless Potential of Mini Lathes

A mini lathe is more than just a compact machining tool; it serves as the starting point for many manufacturing dreams. By selecting the right mini lathe and using it with care, you can bring endless creativity and production potential to your workshop. Whether you’re an artisan, an engineering designer, or an educator, a mini lathe can add precision and a sense of accomplishment to your projects. If you’re considering purchasing a mini lathe, take the time to explore its features and benefits—let it become your reliable assistant in all your machining endeavors.Welcome to visit Minnuo Group’s website and get in touch with us. We look forward to helping you find the perfect equipment.