Imagine trying to assemble a complex machine without the ability to securely fasten parts together. It would be nearly impossible!

Tapped and threaded processes are essential in manufacturing, providing the means to create internal and external screw threads that enable components to be securely fastened together. Tapping refers to creating internal threads (e.g., inside a drilled hole), while threading involves making external threads on cylindrical components (e.g., bolts). These processes are widely used in various industries, from automotive to aerospace, ensuring the durability and integrity of mechanical assemblies.

In this guide, we’ll dive deep into the world of tapped and threaded processes, exploring their differences, applications, and the reasons behind their widespread use in various industries. Along the way, we’ll back up our discussion with relevant data and examples to give you a comprehensive understanding of these essential manufacturing techniques.

What is Threading?

Threading is the process of creating helical grooves on the external surface of cylindrical components, such as bolts, screws, or pipes. These grooves allow the components to be screwed into corresponding internal threads, forming a secure, threaded joint.

Types of Threads

There are various types of threads, classified based on their geometry and application. For example:

- Metric vs. Imperial Threads: Metric threads are measured in millimeters, while imperial threads are measured in inches.

- Coarse vs. Fine Threads: Coarse threads have a larger pitch, making them stronger and more resistant to wear, while fine threads offer greater precision and are less likely to loosen over time.

- Specific Threads: Threads like NPT (National Pipe Thread) are used for sealing pipes, while UNF (Unified Fine Thread) is common in automotive and aerospace applications.

These types of threads are standardized to ensure compatibility and consistency in manufacturing, which brings us to the importance of thread standards.

Thread Standards

Threading is governed by various international standards, including ISO, ANSI, and DIN. These standards ensure that threads are consistent, compatible, and reliable across different applications.

Now that we’ve explored threading, let’s turn our attention to tapping, a process that is often mentioned in the same breath as threading but serves a distinct purpose in manufacturing.

What is Tapping?

Tapping, on the other hand, is the process of creating internal threads within a pre-drilled hole. This allows screws or bolts to be inserted and securely fastened.

Types of Taps

Taps come in different designs, each suited to specific applications:

- Hand Taps vs. Machine Taps: Hand taps are used manually, while machine taps are designed for use with powered tools.

- Taper, Plug, and Bottoming Taps: Taper taps are used to start threading, plug taps are used for intermediate depths, and bottoming taps are ideal for threading to the bottom of a blind hole.

With the variety of taps available, choosing the right one for the job is crucial. This decision is often influenced by the standards and specifications that govern tapping processes.

Tapping Standards and Specifications

Just like threading, tapping adheres to specific standards that dictate the design and application of taps. The choice of tap is influenced by the material being worked on and the desired thread quality.

Tapped vs. Threaded: Comparing the Processes

Having established the fundamentals of tapping and threading, it’s essential to understand how these processes compare and contrast with each other.

Definition and Process Comparison

At their core, tapping and threading serve similar purposes but in different contexts. Tapping is used for creating internal threads, while threading is for external threads. Both processes are integral to manufacturing, but their applications can differ based on factors such as material type, strength requirements, and production volume.

Strength and Durability Considerations

When comparing tapped and threaded joints, strength is a key factor. Tapped holes generally provide strong, reliable joints, especially when used with high-strength fasteners. Threaded connections, on the other hand, are crucial in applications where components must be frequently assembled and disassembled, such as in machinery maintenance.

Cost and Efficiency

In terms of cost-effectiveness, tapping is often more economical for creating internal threads, particularly in high-volume production. Threading, while slightly more complex, is indispensable for creating standardized external threads on bolts and screws.

Application Scenarios

Tapped processes are preferred in applications requiring strong, secure joints in materials such as metal and hard plastics. For example, tapped threads are commonly used in automotive engine blocks. Threaded processes are essential for producing bolts, screws, and other fasteners that are used across industries.

Materials and Tools for Tapping and Threading

As we transition from understanding the processes themselves to the materials and tools required, it’s important to recognize that the choice of materials and tools can significantly impact the success of both tapping and threading operations.

Material Selection

The material being worked on greatly influences the choice of tapping or threading technique. For instance:

- Steel: Often used due to its strength and durability. Tapping and threading steel require robust tools, typically made from high-speed steel (HSS) or carbide.

- Aluminum: Easier to work with, but requires precise control to avoid damaging the threads.

- Brass: Provides good machinability and is often used for precision components.

Each material presents unique challenges and opportunities, necessitating the selection of appropriate tools designed to handle the specific demands of the task.

Tools for Tapping

Advanced tools and machinery, such as CNC machines, have revolutionized tapping. These tools offer greater precision, speed, and repeatability, which are crucial in modern manufacturing environments. Additionally, the selection of tools is heavily influenced by factors such as tap material, coating, and size.

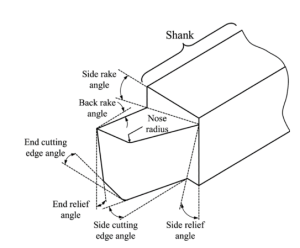

Tools for Threading

Similarly, threading requires specialized tools, from manual dies to advanced CNC threading inserts. The choice of tools depends on the thread type, material, and the required precision. In high-precision environments, the use of advanced threading tools is paramount to achieving the desired thread quality.

Processes and Techniques: From Manual to Advanced

Transitioning from the tools used in tapping and threading, it’s now time to explore the techniques that bring these tools to life. Whether you’re working manually or with advanced machinery, the approach you take can dramatically affect the outcome of your work.

Thread Cutting Techniques

Traditional threading can be done manually using dies or on machines such as lathes. However, modern techniques often involve CNC threading, which offers higher precision and efficiency. This method is particularly beneficial in high-volume production settings where consistency is key.

Tapping Techniques

Similarly, tapping can be done manually or with machines. CNC tapping is particularly useful for high-volume production, where consistency and speed are paramount. The choice between manual and machine tapping depends largely on the production scale and the required precision.

Advanced Techniques

Beyond traditional methods, advanced techniques like thread rolling (a non-cutting process) offer advantages in terms of strength and material efficiency. This method is particularly useful for creating threads in high-strength materials like titanium. Advanced techniques often require specialized equipment and expertise but result in superior quality and durability.

Quality Control and Inspection

As we delve into the realm of quality control, it’s essential to recognize that ensuring the precision and integrity of tapped and threaded components is just as important as the processes themselves. Without rigorous inspection, even the most carefully executed operations can fall short.

Measurement Tools

Ensuring the accuracy of threads and taps is critical for maintaining quality. Tools such as plug gauges and ring gauges are commonly used to verify thread dimensions and tolerance. These tools allow for precise measurement and ensure that the threads meet the required specifications.

Common Defects and Solutions

Despite best efforts, defects like cross-threading or tap breakage can occur, compromising the integrity of a joint. Identifying the root causes of these defects—often related to tool wear, material inconsistency, or improper technique—is key to preventing them. Implementing corrective actions can significantly reduce the incidence of such defects.

Standards for Quality Control

Adherence to industry standards, such as ISO and ANSI, ensures that tapped and threaded components meet the required specifications for safety and performance. These standards provide a framework for quality control processes and help maintain consistency across production batches.

Applications of Tapped and Threaded Components

With quality assured, it’s time to explore the diverse applications of tapped and threaded components. These processes are not just abstract concepts but are used in real-world applications across various industries.

Industrial Applications

In industries like automotive and aerospace, tapped and threaded components are essential. For example, threaded fasteners are used extensively in aircraft assembly due to their strength and reliability. These components ensure that critical parts remain securely fastened even under extreme conditions.

Consumer Product Applications

From electronics to home appliances, tapped and threaded components are found in many consumer products. These components enable easy assembly and disassembly, contributing to product longevity and ease of repair. The ability to easily replace parts extends the life of many consumer goods.

Custom and Specialized Applications

Custom threads are often required for specialized engineering applications. For instance, in the medical device industry, unique thread designs are used in implants to ensure they securely bond with bone tissue. These specialized applications often demand bespoke solutions tailored to specific requirements.

Recent Developments and Innovations

As industries evolve, so do the techniques and technologies associated with tapping and threading. Staying abreast of these developments is crucial for maintaining a competitive edge.

Advances in Technology

Recent advancements in tapping and threading technology, such as the development of specialized coatings for taps and dies, have enhanced the durability and performance of these tools. Additionally, CNC advancements have allowed for more complex thread geometries to be created with greater precision. These technological strides have streamlined production processes and improved product quality.

Material Science Impact

New materials, such as advanced composites and superalloys, present challenges for traditional tapping and threading methods. However, ongoing research and development are leading to innovative solutions that enable effective machining of these materials. The impact of material science on manufacturing cannot be overstated, as it drives the need for continuous improvement in machining techniques.

Future Trends

The future of tapping and threading is likely to see increased automation, with AI and machine learning playing a role in optimizing machining processes. These technologies will enable more efficient production while maintaining high standards of quality and precision. As the manufacturing landscape continues to evolve, those who embrace these innovations will be well-positioned to thrive.

Safety Considerations

As we wrap up our discussion, it’s important to address the safety considerations that must be taken into account when performing tapping and threading operations.

Safety Guidelines

Safety is paramount when performing tapping and threading operations. Key practices include proper machine guarding, use of PPE, and following safe operating procedures to prevent injuries. These guidelines help ensure that workers can perform their tasks safely and effectively.

Common Hazards and Prevention

Hazards such as sharp edges, flying debris, and tool breakage are common in tapping and threading. Implementing safety measures like regular tool inspections and using appropriate coolant can mitigate these risks. By staying vigilant and adhering to safety protocols, many common workplace accidents can be avoided.

Conclusion: The Art and Science of Tapping and Threading

Mastering the art of tapping and threading is essential for any technical engineer or worker involved in manufacturing. These processes, while seemingly simple, are the foundation of countless mechanical assemblies, and their proper execution ensures the strength, reliability, and safety of the end products.

Whether you’re working with traditional materials or cutting-edge alloys, understanding the nuances of tapping and threading will equip you with the skills needed to produce high-quality components. As technology continues to evolve, staying updated with the latest advancements will be key to maintaining efficiency and precision in your work.

FAQs

How do you avoid cross-threading?

To avoid cross-threading, ensure that the threaded components are aligned correctly before assembly. Start the threading process slowly and carefully, applying consistent pressure. Using a lubricant can also help reduce friction and make the threading process smoother.

Is tapped the same as threaded?

Tapped and threaded are related but not exactly the same. Threaded generally refers to the process of creating threads, either internal or external. Tapped specifically refers to the creation of internal threads in a hole, using a tool called a tap. So, while tapping results in a threaded hole, “threaded” can refer to both internal and external threads.

Is a tapped hole threaded?

Yes, a tapped hole is threaded. Tapping is the process of cutting internal threads into a hole, making it possible to insert a screw or bolt with matching external threads. Therefore, after tapping, the hole is considered to be threaded.

What does drilled and tapped mean?

Drilled and tapped refers to a process where a hole is first drilled into a material, and then internal threads are created in that hole using a tapping process. This combination allows for the insertion of screws or bolts into the material, enabling secure fastening. Drilling creates the initial hole, and tapping provides the internal threads needed for the fasteners.

What is the difference between a threaded insert and tapping?

Threaded Insert: A threaded insert is a pre-manufactured component that is inserted into a hole to provide a threaded surface. This is often used to repair damaged threads or to add threads to a softer material. The insert itself has external threads that allow it to be screwed into the base material and internal threads that allow screws or bolts to be inserted.

Tapping: Tapping is the process of cutting internal threads directly into a pre-drilled hole in the base material using a tap tool. It is a method for creating threads without the need for a separate insert.

What is a tapped bolt?

A tapped bolt is not a standard term, but it may refer to a bolt that has had threads cut into it, typically using a tapping process. In practice, bolts are usually manufactured with threads, so they are ready to be screwed into a threaded hole. If a bolt is described as “tapped,” it might imply that it has been modified or re-threaded.