Surface finish plays a crucial role in manufacturing, impacting the performance, longevity, and aesthetics of parts and products. This comprehensive guide will explore various aspects of surface finish, including its definition, measurement techniques, influencing factors, and its importance in different industries.

Surface finish significantly influences manufacturing processes, affecting not only aesthetic appeal but also the functional performance of parts. This guide delves into the factors influencing surface finish, measurement techniques, types of surface finishes, and their applications across various industries. By mastering surface finish, professionals can achieve superior product quality and performance.

Imagine producing a precision-engineered component that fails due to poor surface finish. Such failures can lead to costly downtime, reduced product life, and customer dissatisfaction. Understanding surface finish can prevent these issues and lead to improved product performance and customer satisfaction.

What is Surface Finish

To deeply understand surface finish and its impact on the manufacturing process, we first need to explore its definition, importance, and different measurement parameters. Surface finish affects not only the appearance of parts but also their functional performance. Understanding these basic concepts is essential for any manufacturing or machining task.

Surface finish refers to the texture or smoothness of a surface, characterized by its roughness, waviness, and lay. It is crucial in determining the performance and aesthetics of a part.

Importance of Surface Finish in Various Industries

Different industries have specific surface finish requirements based on functional and aesthetic needs. For example, aerospace components demand extremely smooth surfaces to reduce drag, while medical devices require precise finishes to ensure biocompatibility.

Measurement Parameters

Common parameters include Ra (average roughness), Rz (mean roughness depth), and Rq (root mean square roughness). Each parameter provides different insights into the surface texture.

- Ra (Average Roughness): Ra is the most commonly used surface roughness parameter, representing the average deviation of the surface profile from the mean line. It is usually measured in micrometers (µm).

- Rz (Mean Roughness Depth): Rz represents the average height difference between the five highest peaks and the five lowest valleys on the surface profile, giving a direct sense of surface irregularity.

- Rq (Root Mean Square Roughness): Rq is the root mean square value of surface profile deviations, often used for more precise surface analysis.

Having understood the basic definition and importance of surface finish, we now explore the factors that influence surface finish, helping us better control and optimize the machining process.

Factors Influencing Surface Finish

Surface finish is influenced by various factors, which determine the final quality and performance of the surface. Here are some key factors:

Material Properties: Different materials react differently to machining processes. Metals like aluminum and steel have distinct surface finish characteristics due to their hardness and ductility.

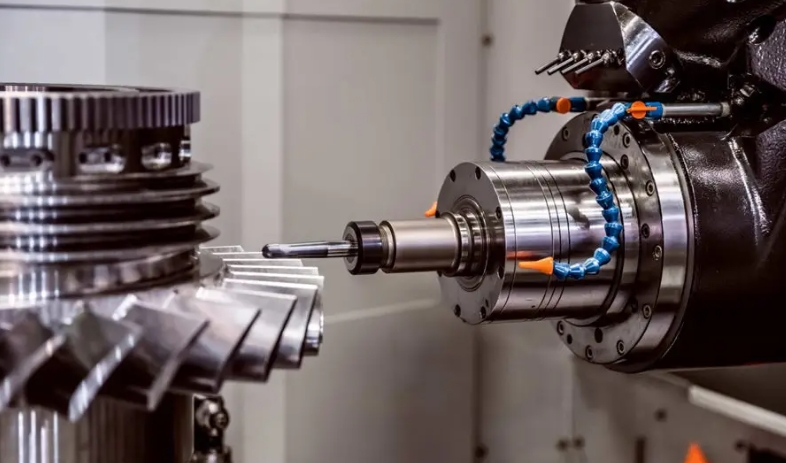

Machining Process: The type of machining process (turning, milling, grinding, etc.) significantly affects the surface finish. For example, grinding typically produces a finer finish compared to milling.

Cutting Tools and Conditions: Tool geometry, material, and wear, along with cutting speed, feed rate, and depth of cut, are critical factors. Optimizing these conditions is essential for achieving the desired surface finish.

Machine Tool Rigidity and Stability: Machine tool vibrations and deflections can adversely affect the surface finish. Ensuring machine stability through proper maintenance and calibration is crucial.

Environmental Factors: Temperature, humidity, and the presence of contaminants can impact the machining process and surface finish.

Understanding these influencing factors, accurate measurement of surface finish is vital to maintaining quality. Let’s explore how to measure surface finish.

How to Measure Surface Finish

There are various methods to measure surface finish, ranging from contact to non-contact methods. Choosing the appropriate measurement technique ensures accuracy and helps optimize the machining process.

Contact Methods (Profilometers)

These devices measure surface roughness by physically contacting the surface. They provide accurate readings for parameters like Ra and Rz.

Data and Example: Profilometers can measure Ra values down to 0.01 µm. For instance, a precision-ground component might have an Ra value of 0.2 µm.

Non-Contact Methods (Optical Interferometry, Laser Scanning)

These techniques use light or lasers to measure surface finish without physical contact, making them ideal for delicate or small components.

Optical Interferometry: Utilizes interference phenomena to measure surface topography, achieving sub-nanometer resolution, suitable for extremely high precision applications.

Laser Scanning: Scans the surface with a laser beam, generating high-resolution 3D surface images. Suitable for quick, non-contact measurements.

Comparison of Methods and Their Applications

Each measurement method has its advantages and limitations. Profilometers are widely used for their accuracy and simplicity, while non-contact methods are essential for non-destructive testing.

Knowing how to measure surface finish is vital, but it is equally important to understand the different types of surface finishes and their applications.

Common Surface Finish Types

There are various types of surface finishes, each with its unique characteristics and applications. Here are some common surface finish types:

- Machined Finish: Created by conventional machining processes like turning and milling. Typical Ra values range from 1.6 to 6.3 µm.

- Polished Finish: Achieved through abrasive polishing processes, resulting in very smooth surfaces with Ra values as low as 0.05 µm.

- Ground Finish: Produced by grinding, offering high precision and fine surface finish with Ra values typically between 0.2 and 0.8 µm.

- Honed Finish: Used primarily for internal surfaces, honing improves roundness and surface finish. Ra values range from 0.05 to 0.4 µm.

- Lapped Finish: Involves using fine abrasive particles to achieve extremely smooth surfaces, often below 0.01 µm Ra.

- Superfinishing: A precision process that enhances surface finish and part geometry, typically achieving Ra values less than 0.1 µm.

Different machining processes can achieve various surface finishes, each with its unique characteristics and applications.

Characteristics of Surface Finish

The characteristics of surface finish include roughness, waviness, and lay. These features affect not only the mechanical performance of the part but also its appearance and lifespan.

Roughness

Composed of small surface irregularities, it is the most common surface feature, typically measured by parameters like Ra and Rz.

Waviness

Larger surface irregularities compared to roughness, often caused by machine tool vibrations or process parameter variations.

Lay

The overall directional pattern of the surface, including machining marks and textures, affecting surface contact and friction performance.

Understanding the characteristics of surface finish, we further explore how symbols and parameters are used to evaluate surface finish, and how to calculate and measure surface roughness.

Symbols and Parameters for Evaluating Surface Finish

Technical drawings and manufacturing specifications often use symbols and parameters to describe and evaluate surface finish. These symbols and parameters provide crucial information about surface quality, ensuring that machined parts meet design requirements.

Common Symbols: Include Ra, Rz, Rq, and are widely used in various technical drawings and specifications.

- Examples: Standardized symbols on technical drawings indicate surface finish requirements, such as N6 (0.8 µm Ra), N7 (1.6 µm Ra) from ISO 1302.

Parameter Explanation: Each parameter provides detailed information about different surface characteristics. For example, Ra provides the average roughness, while Rz indicates the height difference between peaks and valleys.

By introducing standardized symbols and parameters, we can more accurately describe and evaluate surface finish. Next, we discuss how to calculate and measure surface roughness.

How to Calculate and Measure Surface Roughness

Calculating and measuring surface roughness is essential for understanding and controlling the quality of surfaces during machining. Standardized measurement methods and formulas ensure that surface finish meets design and functional requirements.

- Calculation Formula: The formula for calculating Ra is Ra=1/n∑ni=1|yi|, where yi is the deviation of the surface profile, and n is the number of measurement points.

- Measurement Steps: Using a profilometer or other measuring devices, follow standardized steps to measure, record, and analyze data.

- Data Analysis: Analyzing measurement data determines if the surface finish meets design requirements and identifies necessary process adjustments.

After mastering calculation and measurement methods, we explore surface finishes in different machining processes and their characteristics.

Surface Finish in Different Machining Processes

Different machining processes can achieve various surface finishes, each with its unique characteristics and applications.

Turning: Produces cylindrical surfaces. Surface finish depends on tool sharpness, feed rate, and cutting speed. Typical Ra values range from 1.6 to 3.2 µm.

- Example: A turned shaft might have an Ra value of 1.6 µm, suitable for general industrial use.

Milling: Produces flat or complex surfaces. The surface finish is influenced by cutter type, spindle speed, and feed rate. Ra values can vary from 0.8 to 3.2 µm.

- Data: Milling a precision part might achieve an Ra of 0.8 µm with proper tool and parameter optimization.

Grinding: Used for high precision and fine finishes. Ra values typically range from 0.2 to 0.8 µm.

- Example: Grinding a tool steel component can achieve an Ra of 0.4 µm, essential for tool and die applications.

Honing: Improves the geometry and surface finish of internal cylindrical surfaces. Ra values range from 0.05 to 0.4 µm.

- Example: Honing an engine cylinder might achieve an Ra of 0.1 µm, crucial for performance and longevity.

Lapping: Achieves extremely fine finishes using fine abrasives. Ra values are often below 0.01 µm.

- Example: Lapping an optical component can result in an Ra of 0.005 µm, necessary for optical clarity.

Achieving the desired surface finish involves careful selection of tools, parameters, and conditions. Let’s explore how to optimize these factors.

Achieving Desired Surface Finish

Achieving the desired surface finish requires considering factors such as tool selection, cutting parameters, coolant and lubrication use, and machine maintenance.

Tool Selection and Geometry: Choosing the right tool material and geometry (rake angle, clearance angle) is crucial. For example, carbide tools with positive rake angles can improve surface finish in turning.

Cutting Parameters (Speed, Feed Rate, Depth of Cut): Optimizing these parameters reduces tool wear and improves surface finish. High cutting speeds with appropriate feed rates generally produce better finishes.

- Formula: Surface finish Ra can be estimated using Ra=f2/8r, where f is the feed rate and r is the nose radius of the tool.

Use of Coolants and Lubricants: Proper lubrication reduces friction and heat, enhancing surface finish. High-performance coolants can significantly improve the finish.

- Data: Using synthetic coolants can reduce Ra values by up to 20% compared to dry machining.

Machine Tool Maintenance and Calibration: Regular maintenance ensures machine stability and precision. Calibration minimizes errors and ensures consistent surface quality.

Standardizing surface finish requirements ensures consistency and quality across different applications and industries.

Surface Finish Standards and Specifications

To ensure consistency and quality in different applications, industries adopt a series of standards and specifications to describe and evaluate surface finish.

ISO Surface Finish Standards: ISO 1302 specifies surface finish symbols and their use in technical drawings. Common symbols include N6 (0.8 µm Ra), N7 (1.6 µm Ra), etc.

ASME Surface Finish Standards: ASME B46.1 provides guidelines for measuring and specifying surface finish. It includes parameters like Ra, Rz, and Rq.

Industry-Specific Standards: Different industries have specific surface finish requirements. For instance, the aerospace industry might follow stricter standards (e.g., AMS 2451) compared to general manufacturing.

Understanding and adhering to these standards ensures that surface finish meets the necessary criteria for performance and quality.

| Roughness N ISO Grade Numbers | Roughness values Ra micrometers (µm) | Roughness values Ra microinches (µin.) | RMS | CLA (µin.) Center Line Avg. | Rt Roughness, mic100rons |

| N12 | 50 | 2000 | 2200 | 2000 | 200 |

| N11 | 25 | 1000 | 1100 | 1000 | 100 |

| N10 | 12.5 | 500 | 550 | 500 | 50 |

| N9 | 6.3 | 250 | 275 | 250 | 25 |

| N8 | 3.2 | 125 | 137.5 | 125 | 13 |

| N7 | 1.6 | 63 | 64.3 | 63 | 8.0 |

| N6 | 0.8 | 32 | 32.5 | 32 | 4.0 |

| N5 | 0.4 | 16 | 17.6 | 16 | 2.0 |

| N4 | 0.2 | 8 | 8.8 | 8 | 1.2 |

| N3 | 0.1 | 4 | 4.4 | 4 | 0.8 |

| N2 | 0.05 | 2 | 2.2 | 2 | 0.5 |

| N1 | 0.025 | 1 | 1.1 | 1 | 0.3 |

Impact of Surface Finish on Performance

Surface finish significantly affects the performance of parts, influencing their wear resistance, fatigue strength, friction, and lubrication properties.

Impact on Wear Resistance: A smoother surface finish reduces wear and extends component life. Rough surfaces can cause abrasive wear, leading to premature failure.

- Data: Studies show that components with Ra < 0.4 µm exhibit up to 50% longer wear life than those with Ra > 1.6 µm.

Impact on Fatigue Strength: Surface finish influences the fatigue life of components. Rougher surfaces have higher stress concentrations, leading to lower fatigue strength.

- Example: Polishing a high-stress component can improve fatigue life by 20%.

Impact on Friction and Lubrication: Surface finish affects the frictional behavior and lubrication efficiency of moving parts. Smoother surfaces reduce friction and improve lubrication.

- Data: Reducing Ra from 0.8 µm to 0.2 µm can decrease friction by 15%.

Impact on Aesthetic and Functional Properties: Surface finish affects the visual and tactile quality of products. For example, a polished finish enhances the appearance of consumer goods, while a fine machined finish improves sealing surfaces in hydraulic systems.

Real-world case studies highlight the importance of achieving the right surface finish in various applications.

Case Studies

Through some real-world examples, we can better understand the application and importance of surface finish in different industries.

Aerospace Industry: Precision components such as turbine blades require fine surface finishes to reduce drag and improve efficiency. Achieving an Ra of 0.4 µm can enhance performance and reduce fuel consumption.

- Example: A study showed that polishing turbine blades to an Ra of 0.4 µm improved engine efficiency by 2%.

Automotive Industry: Engine components like cylinder walls benefit from honing to achieve optimal surface finish for performance and longevity. An Ra of 0.1 µm can significantly reduce wear and oil consumption.

- Example: Honing cylinder walls to an Ra of 0.1 µm improved engine lifespan by 30%.

Medical Device Industry: Surgical instruments and implants require extremely smooth surfaces to ensure biocompatibility and prevent infection. Polishing to an Ra of 0.05 µm ensures high-quality surfaces.

- Example: Polishing implants to an Ra of 0.05 µm reduced infection rates by 25%.

Electronics Manufacturing: Components like connectors and semiconductor devices need fine finishes to ensure proper functionality and connectivity. Achieving an Ra of 0.01 µm is critical for performance.

- Example: Lapping semiconductor wafers to an Ra of 0.01 µm improved device performance and reliability.

The future of surface finish technology is rapidly evolving with new advancements and trends.

Future Trends in Surface Finish Technology

Surface finish technology continues to advance, driven by the introduction of new materials and techniques.

- Advances in Surface Measurement Technology: New technologies such as 3D surface profilometry and atomic force microscopy (AFM) provide more detailed and accurate measurements of surface finish. 3D profilometry can measure surface features with nanometer accuracy, providing comprehensive surface topography data.

- New Materials and Their Impact on Surface Finish: The development of advanced materials like ceramics and composites requires new surface finish techniques to achieve the desired properties. Diamond-like carbon (DLC) coatings on tools can achieve ultra-smooth surfaces with Ra < 0.01 µm.

- Automation and AI in Achieving Optimal Surface Finishes: Automation and AI technologies optimize machining parameters in real-time to achieve consistent and high-quality surface finishes. AI-driven machining can reduce surface roughness by 20% compared to manual parameter adjustments.

- Sustainability Considerations: Eco-friendly machining practices and materials contribute to sustainable manufacturing while maintaining high surface finish standards. Using biodegradable coolants reduces environmental impact and maintains surface finish quality.

Summarizing the key points helps reinforce the importance of surface finish and its impact on manufacturing.

FAQs

What is a 0.8 surface finish?

A 0.8 surface finish, measured in Ra (Roughness Average), indicates a very smooth surface. Ra is the arithmetic average of surface heights measured across a surface. A 0.8 Ra finish is often specified for parts requiring smooth surfaces for functional or aesthetic reasons.

What does a 125 surface finish mean?

A 125 surface finish refers to a surface roughness value of 125 microinches (

μ

in) Ra. This is a relatively rough surface finish, suitable for parts where high precision and smoothness are not critical.

What is the difference between Ra and Rz in surface finish?

Ra (Roughness Average) is the arithmetic average of absolute values of the surface height deviations measured from the mean line. Rz (Mean Roughness Depth) measures the average of the vertical distance between the five highest peaks and five lowest valleys within a sampling length. Ra provides a general measure of surface texture, while Rz gives more emphasis to the highest peaks and deepest valleys, often resulting in higher values than Ra for the same surface.

How can I improve the surface finish of my machined parts?

To improve the surface finish of machined parts, consider the following methods:

- Use sharper cutting tools to reduce material deformation.

- Increase cutting speeds and reduce feed rates to achieve smoother cuts.

- Apply proper lubrication to minimize friction and heat generation.

- Perform secondary finishing processes such as grinding, polishing, or honing.

- Ensure your machine tools are properly aligned and free from vibration.

What are the latest technologies in surface finish measurement?

Recent advancements in surface finish measurement technologies include:

- Optical Profilometry: Non-contact methods using light to measure surface roughness with high precision.

- Atomic Force Microscopy (AFM): Provides extremely high-resolution measurements at the nanometer scale.

- Laser Scanning Microscopy: Uses lasers to capture detailed surface profiles and analyze roughness.

- 3D Surface Roughness Measurement: Allows for comprehensive analysis of surface texture by capturing data in three dimensions, providing more detailed insights compared to traditional 2D measurements.