In modern manufacturing, CNC (Computer Numerical Control) machine tools have become indispensable. According to different machining needs and application scenarios, CNC machine tools can be categorized into various types. In this article, we will discuss these different types of CNC machine tools in depth to help readers understand the characteristics of each type of machine tool and its application in actual production.

CNC (Computer Numerical Control) machines come in various types, each tailored for specific tasks in manufacturing. The main types include:

- CNC Milling Machines: Utilize rotary cutters to remove material, ideal for creating complex shapes.

- CNC Lathes: Rotate the workpiece against cutting tools, perfect for cylindrical parts.

- CNC Plasma Cutters: Use ionized gas to cut metal sheets with precision.

- CNC Laser Cutters: Employ laser beams for detailed cutting and engraving.

- CNC Routers: Cut softer materials like wood and plastic, common in woodworking.

- CNC Electrical Discharge Machines (EDM): EDM use electrical discharges or sparks to erode material from a workpiece. They are particularly effective for machining hard metals and creating intricate cavities and complex shapes

- CNC Waterjet Cutting Machines: Use a high-pressure stream of water mixed with abrasive particles to cut through a wide range of materials, including metal, stone, and glass.

- CNC Grinding Machines: Utilize abrasive wheels to remove material and achieve high-precision finishes on a workpiece.

- 3D Printers: Create three-dimensional objects by layering material based on digital models. They can use various materials, such as plastics, metals, and composites.

- CNC Bending Machines: are designed to bend and shape sheet metal and tubing into desired angles and configurations.

Ready to explore the fascinating world of CNC machines? Discover the different types and functionalities that will leave you wanting to learn more!

Introduction to CNC Machines

CNC (Computer Numerical Control) machines are an essential tool in modern manufacturing. They use computer control technology to operate various machines and tools through pre-programmed software, achieving precise manufacturing and machining. CNC machines are widely used in various industrial fields such as automotive, aerospace, medical equipment, and furniture manufacturing. Their high efficiency, precision, and automation make them indispensable in modern manufacturing.

Types of CNC Machines

There are more than a dozen types of CNC lathes, and in this article, we have categorized CNC machines into 5 common types and a few others.

5 Common Types of CNC Machines

1. CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a workpiece. They can perform drilling, tapping, milling, and other operations, usually with three axis (X, Y, Z) movement, and some high-end models also have a fourth and fifth axis.

Advantages:

High precision and repeatability: Achieve high precision machining through accurate computer control.

Versatility: Suitable for various machining operations, including surface milling, end milling, drilling, and tapping.

High automation: Reduce manual intervention and improve production efficiency.

Disadvantages:

High cost: High precision and multifunctional CNC milling machines are expensive.

Complex maintenance: Require professional personnel for maintenance and upkeep.

Applications: Widely used for manufacturing complex parts and molds, such as automotive parts, aerospace components, and precision molds.

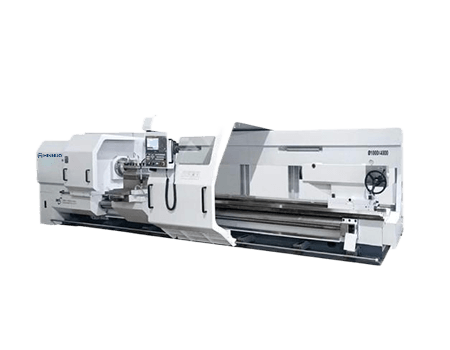

2. CNC Lathes and Turning Machines

CNC lathes are mainly used for rotating workpieces, performing machining through turning, boring, etc. They usually have two axis (X, Z) movement, and some models have a Y-axis and other auxiliary axis.

Advantages:

Efficient machining: Suitable for mass production of cylindrical parts, with high speed and efficiency.

High precision: Achieve high precision turning operations through numerical control.

High automation: Can automatically change tools and adjust machining parameters.

Disadvantages:

Limited application range: Mainly suitable for cylindrical parts, not complex shapes.

High initial investment: High-quality CNC lathes are expensive.

Applications: Widely used for manufacturing shafts, cylindrical parts, tubes, etc., such as automotive shafts, aircraft shafts, and industrial bearings.

3. CNC Plasma Cutters

CNC plasma cutters use high-temperature plasma to cut metal materials. Plasma is generated by an electric arc and high-speed gas flow, capable of quickly melting and cutting metal.

Advantages:

Fast cutting speed: Faster than traditional cutting methods, suitable for mass cutting.

Wide cutting range: Can cut various metals, including steel, stainless steel, and aluminum.

Low cost: Plasma cutting equipment is cheaper compared to laser cutting.

Disadvantages:

Lower cutting precision: Compared to laser cutting, plasma cutting precision is slightly lower.

Large heat-affected zone: The high temperature generated during cutting affects the material’s properties.

Applications: Widely used in metal structure manufacturing, metal processing, shipbuilding, and construction industries.

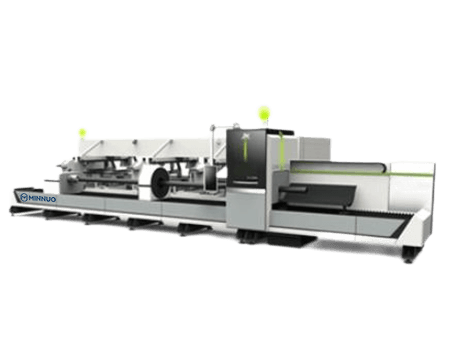

4. CNC Laser Cutting Machines

CNC laser cutting machines use laser beams for high-precision cutting. Lasers are generated by fiber or CO2 laser systems and can form high-energy spots on the material surface for cutting.

Advantages:

High cutting precision: Achieve very fine cutting edges and complex shapes.

Wide cutting range: Suitable for metals, plastics, wood, and fabrics.

Small heat-affected zone: Concentrated heat during cutting reduces the thermal effect on the material.

Disadvantages:

High cost: Laser cutting equipment and maintenance are expensive.

Relatively slow speed: Slower than plasma cutting, but higher precision.

Applications: Widely used in electronics manufacturing, metal part processing, advertising signs, and medical device manufacturing.

5. CNC Routers

CNC routers are suitable for cutting and engraving wood, plastic, and soft metals. They usually have three axis (X, Y, Z) movement and can perform complex three-dimensional engraving and cutting operations.

Advantages:

Versatility: Can perform cutting, engraving, and hollowing operations.

High precision: Achieve high precision engraving and cutting through numerical control.

Wide range of materials: Suitable for wood, plastic, composites, and soft metals.

Disadvantages:

Limited application range: Mainly suitable for non-metals and soft metals, not hard metals.

High maintenance requirements: Requires regular maintenance and upkeep to maintain precision and performance.

Applications: Widely used in furniture manufacturing, advertising, handicraft production, and architectural decoration.

CNC Electrical Discharge Machines (EDM)

CNC EDM machines use electrical sparks to erode metal, making them great for making complex molds and precision parts. EDM technology can process very hard materials like carbide and hardened steel, which is why it’s so popular in mold manufacturing and aerospace.

CNC Waterjet Cutting Machines

CNC waterjet cutting machines use high-pressure water mixed with abrasives to cut, making them great for cutting all sorts of materials, including metals, glass, and composites. Waterjet cutting technology provides a cut without any heat, which is great for making high-precision, deformation-free parts.

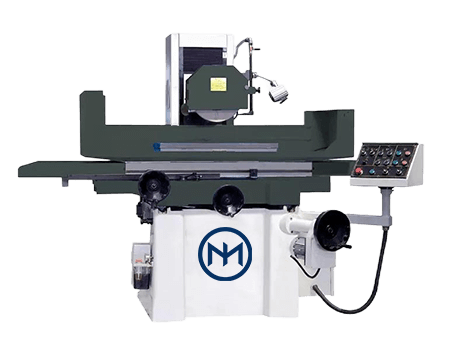

CNC Grinding Machines

CNC grinding machines use grinding to make high-precision parts, which is why they’re so popular in the automotive and aerospace industries. CNC grinding machines can do high-precision internal and external cylindrical grinding and surface grinding, which is why they’re so great for making high-precision shafts and gear parts.

3D Printers

3D printers use additive manufacturing to make three-dimensional objects by adding material layer by layer. 3D printing is great for rapid prototyping, small-batch production, and making complex geometric parts.

CNC Bending Machines

CNC bending machines use computer-controlled methods to bend metal sheets with precision. Bending machines are great for making metal frames, enclosures, and other parts that need precise bending.

Type of CNC Machine Structure

CNC machines can be classified based on what they do and how they’re built:

Vertical CNC Machines

Vertical CNC machines have a spindle that’s oriented vertically, which makes them great for most milling and drilling operations. This design gives you good visibility and makes them easy to use, which is why they’re so popular in mold manufacturing and small-batch production.

Horizontal CNC Machines

Horizontal CNC machines have a spindle that’s oriented horizontally, which makes them great for machining large workpieces, especially ones that need to be machined at multiple angles. The horizontal design makes it easier to get the chips out when you’re machining, which is why they’re so great for large-scale production.

Gantry CNC Machines

Gantry CNC machines have a fixed worktable, with the spindle head moving within the gantry frame. This design makes it possible to machine really big workpieces, which is why they’re so popular in aerospace and shipbuilding for machining large parts.

Types of CNC Machine Axis

CNC machines can be classified by the number of axis and their movement:

3-Axis CNC Machines

3-axis CNC machines have X, Y, Z axis movement, suitable for basic machining operations. This design is suitable for most milling and drilling operations, widely used for manufacturing complex parts.

4-Axis CNC Machines

4-axis CNC machines add a rotational axis to the three axis, allowing for more complex machining. The 4-axis design enables machining more surfaces and angles in a single setup, improving efficiency and precision.

5-Axis CNC Machines

5-axis CNC machines have two rotational axis in addition to the X, Y, Z axis, capable of machining very complex geometries. 5-axis machines are widely used in aerospace, automotive, and medical device manufacturing, providing extremely high precision and flexibility.

12-Axis CNC Machines

12-axis CNC machines include more rotational and movement axis for ultra-high precision and complexity machining tasks. The 12-axis design allows the machine to complete all machining steps in a single setup, significantly improving production efficiency and precision.

Types of CNC Machine Control Methods

Point-to-Point Control CNC Machines

Primarily used for drilling, tapping, and other point-specific machining operations, these machines control the tool’s movement from one point to another.

Continuous Path Control CNC Machines

These machines control the tool to move along a specific path continuously, making them suitable for lathes, milling machines, and similar equipment.

Contour Control CNC Machines

Designed for machining complex surfaces and contours, these machines can simultaneously control the movement of multiple coordinate axis.

Types of CNC Machine Applications

CNC machines have a wide range of applications in different fields and can be classified according to their usage:

General CNC Machines

General CNC machines are used for various machining tasks such as milling, turning, drilling, and grinding. They are versatile and suitable for machining different materials and parts. General CNC machines are widely used in automotive, aerospace, mold, and machinery manufacturing.

Special Purpose CNC Machines

Special purpose CNC machines are designed for specific tasks such as gear cutting, thread cutting, and tube bending. They are specialized for a particular type of part or machining process, offering higher efficiency and precision. Special purpose CNC machines are typically used for mass production and high-precision machining, such as electronics manufacturing and medical equipment production.

How to Buy the Best CNC Machine

Consider the following points when purchasing a CNC machine:

Determine Your Needs: Identify your production needs and budget to choose the appropriate machine type and specifications. Consider the materials you need to process, the complexity of the parts, and the production volume to select the most suitable CNC machine.

Check the Machine’s Features: Examine the machine’s features, control system, and technical parameters to ensure it meets your machining requirements. Understand the maximum machining size, spindle speed, tool magazine capacity, and other key parameters to ensure it suits your production needs.

Consider the Brand and After-Sales Service: Choose reputable brands and understand their after-sales service and technical support. Quality after-sales service ensures timely maintenance and repair during use, reducing downtime and maintenance costs.

Inspect the Machine’s Quality: If possible, inspect the machine’s manufacturing process and quality control to ensure its stability and reliability. Understand the machine’s manufacturing process and quality management system through on-site inspections to ensure it meets your quality requirements.

Summary

CNC machines are essential tools in modern manufacturing, offering a variety of types and powerful functions. Understanding the different types of CNC machines and their applications can help you choose the most suitable machine, enhancing production efficiency and product quality. When purchasing a CNC machine, consider your specific needs, machine technical parameters, and the brand’s after-sales service to ensure you get a high-cost-performance product.

FAQs

What is the most used CNC machine?

CNC milling machines are highly versatile and capable of performing a wide range of machining operations such as drilling, cutting, and shaping materials like metal, plastic, and wood. CNC milling machines come in various configurations, such as vertical and horizontal milling machines, to accommodate different production needs.

Are CNC machines expensive?

CNC machines are relatively expensive machining investments, and the choice of CNC machine is often influenced by the type and accuracy of the workpiece. Entry-level, benchtop, and mini ones in this category will be relatively inexpensive.