In the fields of industrial manufacturing and mechanical engineering, threads are essential components for connections, transmission, and sealing applications. You can find threads in everything from automobiles to aerospace and everyday devices. Choosing the right type of thread not only affects the performance of the product but also enhances the overall efficiency and reliability of operations. However, the design differences and usage environments of various threads lead us to consider: what type of thread is the best choice?

The types of threads and their geometric parameters are key to their design. Different thread types, such as straight threads and tapered threads, meet various usage needs. Additionally, geometric parameters like pitch, lead, and outer diameter affect the fastening effect, transmission efficiency, and tensile strength of the threads. By understanding these basic concepts, you can choose the most suitable thread to address various industrial applications.

Next, this article will guide you to explore thread types and geometric parameters in depth. We will analyze their applications and selection criteria in different scenarios. With this guidance, you will learn how to choose the optimal thread solution based on your needs in practical work. This will help you improve work efficiency and ensure the safety and stability of connections.

What is a thread?

A thread is a mechanical structure that features a helical groove, typically wrapped around a cylindrical or conical surface. It connects, secures, transmits, and seals parts through rotational motion. Threads are widely used in mechanical engineering, manufacturing, construction, and everyday devices. They are core components of fasteners such as screws, nuts, and bolts.

The basic principle of threads is to convert torque into linear motion. This allows for the tightening or loosening of connections during rotation. The “lead” or “pitch” of a thread indicates how far it moves along the axis after one complete rotation. This feature effectively transforms rotational motion into precise linear displacement. As a result, threads are suitable not only for fastening but also for transmitting power or making fine adjustments in equipment.

Main Functions of Threads

Fastening and Connecting: Threads can securely connect two or more parts together. This prevents relative movement or disconnection.

Transmitting Power: Threads can convert rotational motion into linear motion. They are often used in mechanical transmissions, such as feed screws in machine tools.

Sealing: In pipelines or pneumatic devices, threads achieve sealing through a tight fit. This prevents the leakage of liquids or gases.

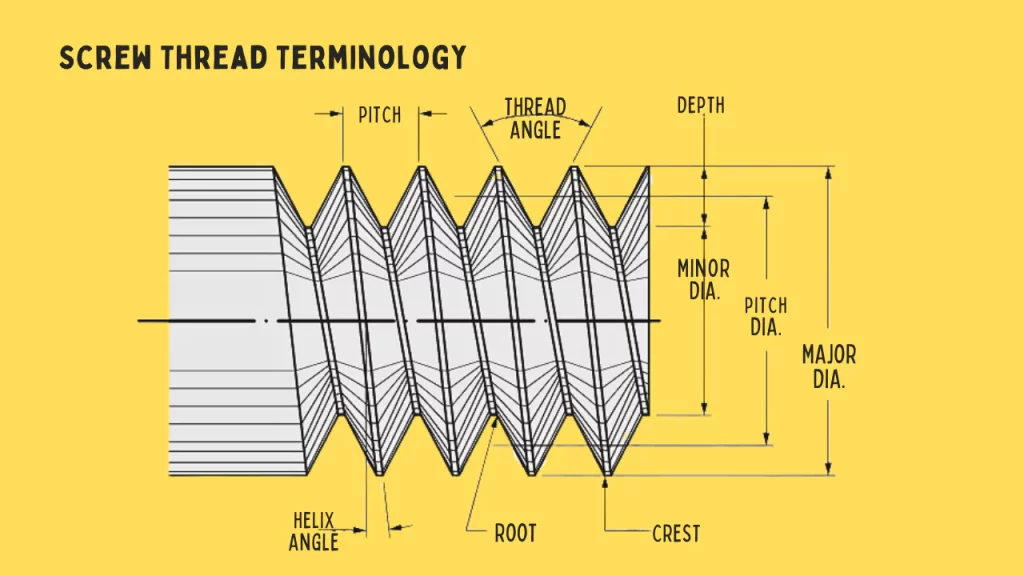

Geometric Parameters of Threads

The geometric parameters of threads are key factors that determine their performance and applicability. By precise geometric design, one can optimize the fastening, transmission, and sealing effects of threads. Below are the main geometric parameters of threads and their functions:

Major Diameter

The major diameter is the maximum diameter at the crest of the thread. It usually determines the overall size of the bolt. A larger major diameter generally increases the tensile strength of the thread. Precise control of the major diameter is crucial for ensuring the fitting accuracy and connection firmness.

Minor Diameter

The minor diameter is the minimum diameter at the root of the thread. It directly impacts the tensile capacity of the thread. The accuracy of the minor diameter is important for the matching of internal and external threads. A larger minor diameter may reduce the strength of the thread.

Pitch Diameter

The pitch diameter is located between the crest and the root of the thread. It is the theoretical diameter where the thread surface is tangent to a cylinder. The pitch diameter directly influences the degree of fit between threads and is a key parameter for measuring thread precision. A more accurate pitch diameter results in better connection stability.

Pitch

The pitch refers to the axial distance between adjacent thread crests. A larger pitch allows for faster assembly but reduces the precision of the connection. A smaller pitch is suitable for applications requiring high-precision connections and can withstand greater loads. Choosing the right pitch ensures effective fastening.

- Large Pitch: Used for connections requiring quick assembly, suitable for rapid disassembly situations.

- Small Pitch: Used for connections with high precision, capable of bearing larger loads.

Lead

Lead is the distance moved axially after one full rotation of the thread. For single-threaded screws, the lead equals the pitch. For multi-threaded screws, the lead is a multiple of the pitch. Threads with a large lead are suitable for devices requiring fast movement, such as drive screws.

Thread Angle

The thread angle is the angle between the faces of the threads on either side. Different thread angles affect the friction and fastening force of the threads. Common thread angles include 60° (like metric threads) and 55° (like British standard threads). A larger angle increases friction, suitable for applications needing stable connections.

Flank Angle

The flank angle is the angle between the two faces of the thread cross-section. It affects the self-locking ability and connection stability of the thread. Different flank angle designs cater to various application needs, such as triangular, square, and trapezoidal threads.

- Triangular Threads: Such as metric and imperial threads, are suitable for general connections and have good self-locking performance.

- Trapezoidal Threads: Used in lead screws, like machine tool guides, are better for bearing heavy loads.

- Square Threads: Provide efficient transmission with low friction, commonly used in jacks and similar devices.

- Sawtooth Threads: Suitable for unidirectional loading, like hydraulic equipment and heavy-duty threaded connections.

Thread Direction

Thread direction is divided into right-hand and left-hand. Right-hand threads are the most common type. Left-hand threads are used for specific applications, such as preventing loosening due to the direction of rotation during operation.

Characteristics and Applications of Right-Hand and Left-Hand Threads

Right-Hand Thread

Right-hand threads are those that screw in by turning clockwise. This means that when you turn to the right, the thread advances along the axis.

Characteristics:

Right-hand threads are the most common type of thread. They are suitable for most everyday mechanical assemblies and fastening applications. People typically tighten clockwise and loosen counterclockwise, making them intuitive and convenient to use. Most mechanical parts and fasteners, such as bolts and nuts, use right-hand threads. This choice promotes universality and standardization.

Applications:

Right-hand threads are widely used in industrial manufacturing, construction assemblies, and various fasteners in everyday life. They are the preferred choice for standardized fasteners.

Left-Hand Thread

Left-hand threads are those that screw in by turning counterclockwise. This means that when you turn to the left, the thread advances along the axis. Left-hand threads are mainly used to prevent loosening in specific situations or in mechanical devices that rotate in reverse.

Characteristics:

Left-hand thread tighten by turning counterclockwise and loosen by turning clockwise, which is the opposite of right-hand thread. Because left-hand threads are less common, they are less likely to be mistakenly operated. This makes them particularly effective in situations where vibrations or reverse rotation could cause loosening. Left-hand threads are designed for components in drive systems that rotate in the opposite direction, ensuring stable connections.

Applications:

Left-hand threads are mainly used in specific conditions, such as:

- Rotating Parts in Machinery: In some rotating components, left-hand threads prevent loosening due to inertia. For example, left-hand threads may be used on the left-side nuts of car tires to ensure a secure connection.

- Hydraulic and Pneumatic Systems: Some pipe fittings use left-hand threads to distinguish between different functional connections and to avoid misoperation.

- Industrial and Engineering Machinery: In certain special machinery and large equipment, left-hand threads are often used to counteract reverse stress.

Different Types of Threads

Choosing the right thread type depends on application needs, load capacity, sealing performance, and self-locking ability. Different thread designs suit various connection and transmission scenarios. Here are some common thread types along with their features and applications:

Metric Thread

Metric threads follow ISO standards and are widely used in global industrial manufacturing. They are measured in millimeters with a 60° thread angle, available in coarse and fine specifications.

- Coarse Thread: These have a larger pitch, suitable for general assembly connections and easy disassembly.

- Fine Thread: These have a smaller pitch, providing higher connection strength and vibration resistance. They are ideal for applications requiring high precision and anti-loosening, such as in precision machinery and the automotive industry.

Unified Thread / British Standard Thread

Unified threads are set by the UK and the US, measured in inches, and commonly found in North America and the UK. They feature a 60° cross-sectional angle, with the following types:

- UNC (Unified National Coarse): Used for general connections with larger pitch for quick assembly, primarily in automotive, construction, and machinery sectors.

- UNF (Unified National Fine): These threads have a smaller pitch and are highly resistant to vibration, suitable for high-strength connections in sensitive environments.

- BSW (British Standard Whitworth): This type features a 55° angle, used in traditional machinery, often under heavy loads and vibrations.

Pipe Thread

Pipe threads are designed for piping systems to ensure the sealing of liquids or gases. Their features include a tapered design for a secure fit in fluid transmission lines. Common standards include NPT and BSP.

How to Identify NPT and BSP Threads:

- NPT (National Pipe Tapered): This American standard has a 60° angle with a 1:16 taper, offering self-locking properties suitable for high-pressure systems.

- BSP (British Standard Pipe): It includes parallel thread (BSPP) and tapered thread (BSPT), featuring a 55° angle. BSPT provides self-locking seals, while BSPP is used in low-pressure systems with sealing washers.

Self-Tapping Thread

Self-tapping threads can directly screw into softer materials like plastic, wood, and lightweight metals without pre-drilled holes, creating a tight self-locking connection.

- Features: These threads automatically cut or form matching internal threads during installation, making assembly convenient.

- Applications: Widely used in electronics, furniture assembly, and plastic products, suitable for quick assembly without high-strength requirements.

Trapezoidal Thread

Trapezoidal threads feature a 30° angle, balancing transmission efficiency and load capacity. Their wide cross-section is ideal for high-load transmission applications.

- Features: They have low friction and high load-bearing capacity, making them suitable for transmission screws and heavy machinery.

- Applications: Commonly found in machine tool screws, elevators, and compression equipment that require efficient force transmission.

Square Thread

Square threads have a square cross-section, offering high transmission efficiency and minimal friction. They are suitable for high-precision and efficient transmission applications.

- Features: Low friction and high efficiency, but complex to manufacture.

- Applications: Mainly used in high-load transmission systems, such as jacks and lead screws in heavy equipment.

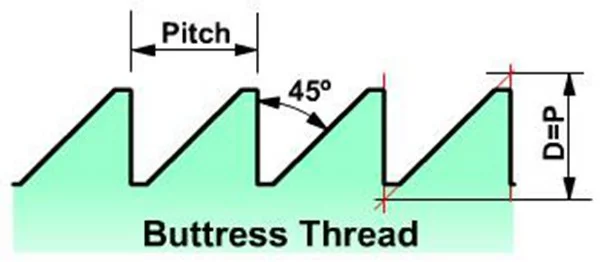

Acme / Buttress Thread

Acme threads are designed for unidirectional load applications, often used in hydraulic systems. One side features a right angle or nearly right angle, allowing them to handle large unidirectional loads.

- Features: They combine advantages from both square and trapezoidal thread, providing high load capacity for axial loads.

- Applications: Commonly used in hydraulic equipment, heavy-duty clamps, and applications requiring unidirectional transfer of large loads.

What Are Single-Thread and Multi-Thread Threads?

In the design of mechanical thread, single-thread and multi-thread types are classified based on the number of thread starts (the number of initial points of the thread). The main difference between these two types is the distance they advance axially (lead) with each complete rotation.

Single-Thread Thread

A single-thread thread is the most common type, having only one thread start. This means that when the thread rotates once, it advances axially by a distance equal to its pitch. Therefore, the lead and pitch of a single-thread thread are the same.

Characteristics:

- The single-thread thread has a simple structure and lower manufacturing costs.

- Due to its relatively slow advancement speed, it offers high self-locking capability, making it resistant to loosening from vibrations or loads.

- It provides strong fastening power, making it suitable for high-strength connections.

Applications:

Single-thread thread is commonly used in situations requiring high fastening force and stability, such as bolts, nuts, and general mechanical fasteners.

Multi-Thread Thread

A multi-thread thread has multiple thread starts, typically two, three, or more. The design of multi-thread threads allows them to advance a greater axial distance with each rotation than single-thread threads (lead = pitch × number of starts). Thus, the lead is a multiple of the pitch.

Characteristics:

- Multi-thread threads advance a greater distance with each rotation, allowing for faster assembly and disassembly, making them ideal for applications requiring quick feeding or adjustment.

- They have lower locking capability, making them prone to loosening in dynamic or high-vibration environments, so they often require additional locking mechanisms.

- They provide smooth transmission but have larger thread profiles, resulting in higher manufacturing and processing costs.

Applications:

Multi-thread threads are suitable for quick assembly and low-load transmission situations. They are commonly found in adjustment screws, bottle caps, and machine tool lead screws, where fast feeding is necessary.

Conclusion

Threads play a crucial role in industrial manufacturing. Different types and geometric parameters of threads meet various connection, transmission, and sealing needs. By selecting the right type of thread, one can ensure product performance, stability, and efficiency, providing reliable support for various mechanical applications.

In the industrial manufacturing field, choosing the appropriate thread design is essential for ensuring connection strength and equipment reliability. Similarly, selecting the right machine tools directly affects production efficiency and machining precision. Minnuo Machine Tools is committed to providing customers with high-precision and high-efficiency equipment. This commitment ensures that every step, from thread processing to complex part manufacturing, is rigorous and reliable. Our machine tools support the precise processing of various thread types while maintaining long-term stability in high-load and high-strength production environments.