Vertical Machining Center

In search of cheap, high-quality CNC vertical machining center? We manufacture a wide range of vertical machining centers:small, medium and large types, with a choice of 3, 4 and 5 axis. With our advanced technology, we can provide you with high-precision, high-speed, and high-quality machinery at competitive prices. Achieve maximize automation with our mature technology for efficient machinery production.

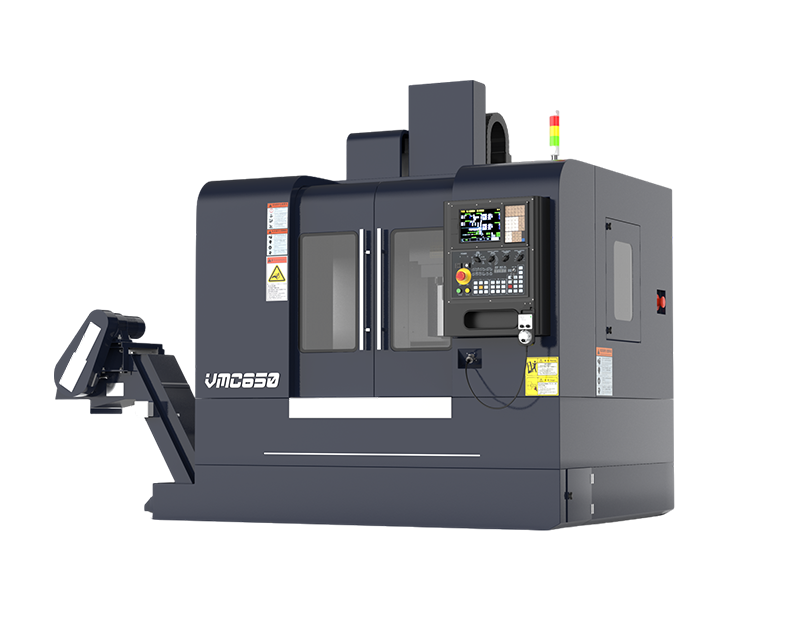

VMC650

Vertical machining center

- Table size(mm): 900x400

- X/Y/Z axis travel(mm):650x400x500

- Table maximum load:350kg

- Spindle power/speed: 7.5KW/8000rpm

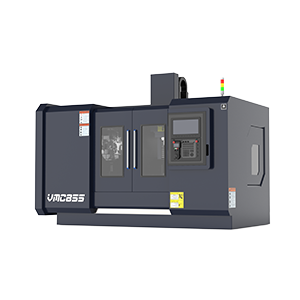

VMC855

Vertical machining center

- Table size(mm): 1000x550

- X/Y/Z axis travel(mm):800x550x550

- Table maximum load:500kg

- Spindle power/speed: 11KW/8000rpm

VMC950

Vertical machining center

- Table size(mm): 1000x500

- X/Y/Z axis travel(mm):950x500x550

- Table maximum load:600kg

- Spindle power/speed: 7.5KW/8000rpm

VMC1050

Vertical machining center

- Table size(mm): 1000x530

- X/Y/Z axis travel(mm):1000x500x600

- Table maximum load:600kg

- Spindle power/speed: 11KW/8000rpm

VMC1060

Vertical machining center

- Table size(mm): 1200x600

- X/Y/Z axis travel(mm):1000x600x600

- Table maximum load:800kg

- Spindle power/speed: 11KW/8000rpm

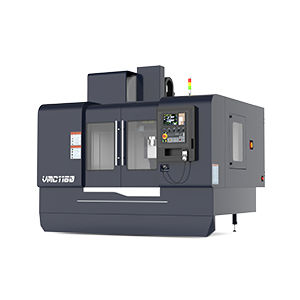

VMC1160

Vertical machining center

- Table size(mm): 1200x600

- X/Y/Z axis travel(mm):1100x600x600

- Table maximum load:1000kg

- Spindle power/speed: 15KW/8000rpm

VMC1270

Vertical machining center

- Table size(mm): 1300x700

- X/Y/Z axis travel(mm):1200x700x600

- Table maximum load:1200kg

- Spindle power/speed: 15KW/8000rpm

VMC1370

Vertical machining center

- Table size(mm): 1500x700

- X/Y/Z axis travel(mm):1300x700x700

- Table maximum load:900kg

- Spindle power/speed: 15KW/8000rpm

MN1312

Vertical machining center

- Table size(mm): 1400x1050

- X/Y/Z axis travel(mm):1300x1250x600

- Table maximum load:1500kg

- Spindle power/speed: 18.5KW/6000rpm

MN2016

Vertical machining center

- Table size(mm): 1400x2000

- X/Y/Z axis travel(mm):2000x1500x700

- Table maximum load:3000kg

- Spindle power/speed: 18.5KW/6000rpm

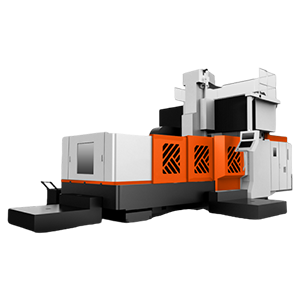

MN3018

Vertical machining center

- Table size(mm): 3000x1500

- X/Y/Z axis travel(mm):3200x1900x750

- Table maximum load:8000kg

- Spindle power/speed: 26KW/8000rpm

MN3022

Vertical machining center

- Table size(mm): 3000x1800

- X/Y/Z axis travel(mm):3200x2300x1000

- Table maximum load:10000kg

- Spindle power/speed: 26KW/8000rpm

Video

Minnuo Group Co., Ltd. is located in Jiangsu Province, China, and was founded in 1987. Currently, we have grown to become one of the leading CNC machinery manufacturers in China. With a factory area of 100,000 square meters and over 400 employees, we have an annual export value exceeding $80 million. Our products are sold to more than 50 countries worldwide. We warmly welcome customers from all over the world to visit our factory.

The main purpose and characteristics ofVertical Milling Machine.

The working principle of vertical machining is to perform cutting on a workpiece by fixing it on a worktable and cutting in the direction perpendicular to the worktable. Vertical milling machines or vertical machining centers are commonly used for vertical machining. The spindle is responsible for driving the milling cutter to rotate, while the worktable moves in the vertical direction of the spindle to achieve the cutting operation.

Features

Efficiency: Vertical machining has higher processing efficiency compared to horizontal machining. This is because the milling cutter in vertical machining can enter and exit the workpiece at a faster speed.

High precision: Vertical machining is less likely to cause workpiece displacement, resulting in higher machining precision. This is particularly crucial for producing high-precision components such as aerospace parts.

Versatility: Vertical machining can be applied to the machining of workpieces with various shapes and is suitable for various complex process requirements.

High safety: During vertical machining, the milling cutter is perpendicular to the worktable, reducing the possibility of the operator being injured by the tool. Additionally, due to the fast speed at which the milling cutter enters and exits, the operation is comparatively stable, minimizing extensive vibrations and reducing the likelihood of safety accidents.

Application Fields

Vertical machining has been widely applied in fields such as aerospace, automotive, shipbuilding, railway, and mechanical manufacturing. It is an ideal choice for producing high-precision components and achieving high-load, high-efficiency production. In the aerospace industry, vertical machining is the preferred method for manufacturing rocket components, launcher assemblies, and satellite parts. In the automotive manufacturing industry, it can be used to manufacture automobile engines and chassis parts. Vertical machining will find increasingly extensive applications in various sectors of modern industrial production.

How to choose the right VMC?

Vertical machining centers refer to machining centers where the spindle axis is perpendicular to the worktable. They can perform various processes such as milling, boring, drilling, reaming, tapping, and more. As a crucial machine in the industrial sector, for workers to give their best, they must first sharpen their tools. Let’s take a look at how we should choose when purchasing a vertical machining center.

Machine Bed

The quality of the machine bed is a critical component of machine tool manufacturing. If the foundation is not solid, it’s like having no water source for water or no roots for a tree. The working environment of a machining center involves vibrations. To maintain machine stability, the materials must be appropriate, and the structure must be reasonable. Additionally, each axis should have a pre-tensioning design to effectively eliminate backlash and ensure more stable mechanical transmission.

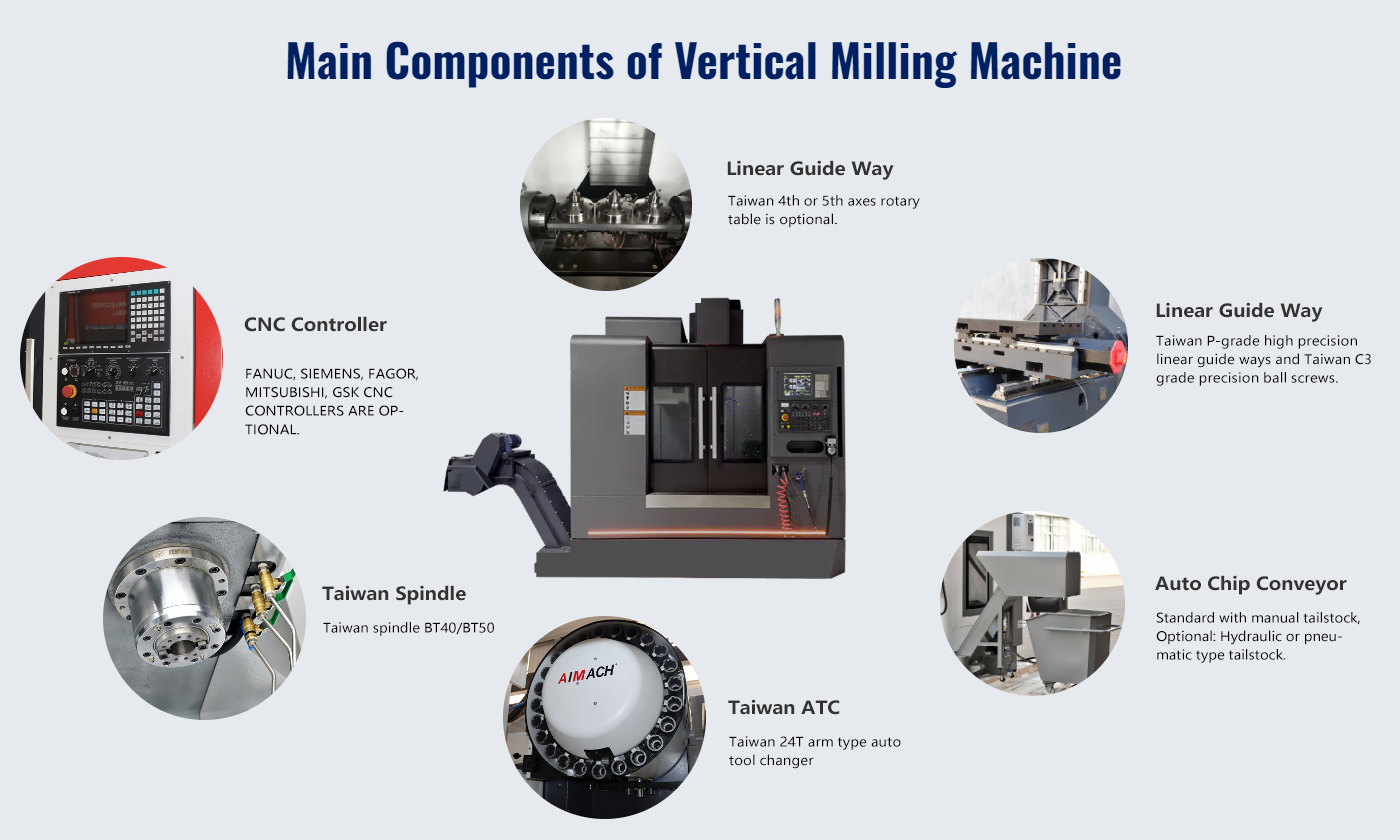

Spindle

The spindle is a key functional part. Gear-driven spindles can automatically switch between high and low speeds, achieving high rigidity, and are suitable for heavy-duty cutting situations, usually operating at speeds below 6000 RPM. Belt-driven spindles have a simple structure and strong buffering capability. Overload sliding protection devices can effectively safeguard the spindle. Direct-drive spindles are driven by a servo motor directly through couplings, providing high torque and low energy consumption.

Lubrication System

Proper lubrication is indispensable in reducing wear, ensuring the normal operation of the vertical machining center. All components involved in motion need to be lubricated. If the machine tool lacks a lubrication system, its lifespan and accuracy will be significantly affected.

Guide Rails

Choosing between linear guide rails or hard guide rails is a common consideration when selecting a machining center. Generally, except for long-term heavy-duty cutting machine tools, linear guide rail machining centers are preferred over hard guide rail machining centers.

Tool Magazine

Common types of tool magazines include disc-type, hat-type, and robot-type. Hat-type tool magazines have a tool change time greater than 8 seconds, while mechanical tool magazines have a tool change time greater than 4 seconds.

Features

Several outstanding features can help reduce labor input and machine wear during operations:

Chip conveyor

Z-axis counterbalance cylinder

Oil-water separator

Collision prevention device

A highly efficient vertical machining center can reduce the complex and labor-intensive tasks such as installation, adjustment, and multiple tool setting for the workpieces, significantly reducing non-machining time, simplifying the production process, lowering the defect rate, and reducing production costs. Therefore, caution should be exercised when purchasing a machine tool.

We have a professional technical team, come and compare prices and services

Frequent Asked Question

The appearance are similar, but the models, parameters and configurations are different, so the prices are different. The better configuration, the higher prices. If you want to get an exact quotation, please contact customer service.

Yes, we can. Please provide the specification for the machine you need, and tell us your requirements.

Please provide the requirements of the products you need to process: drawings, dimensions, size of workpeices etc.

we will recommend the suitable model for you according to the products you need to process.

FOB, CFR and CIF all acceptable.

T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight .

1 set .(Only some low cost machines will be more than 1 set )

© 2022 All rights Reserved. Design by MINNUO Group

- cncitd@minnuo.com

- +8613295238763