CNC Press Brake

Home > CNC Press Brake > WC67K

PRODUCT CATEGORY

Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machining centers

+Related News

WC67K

- Warranty : 1 Year for machinery warranty

- Availability : On Stock

- WhatsApp : +86-13295238763

- Wechat : +86-13295238763

- Email : cncitd@minnuo.com

- (your request will be responsed within 1 hour.)

WC67K description

The MINNUO WC67K Hydraulic CNC Press Brake Machine is our popular and reliable model. It has a stable structure and high precision bending, thanks to studies on framework flections. It also has the option for manual crowning and allows for upgrades. Our machinery is constructed with high-quality parts and features Y-axis Torsion bar syncro technology for fast and precise operation. We offer competitive pricing for our machinery, which comes equipped with advanced DELEM DA41S graphical controls. Additionally, customers have the flexibility to choose from other CNC control systems as well.

Composition

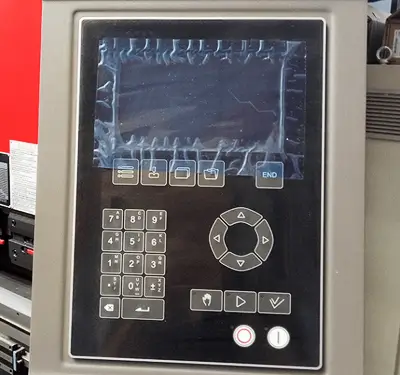

DELEM CNC Control System

MINNUO has opted for the advanced DELEM DA41s, which provides superior programming and control for press brakes. This top-notch Dutch design and meticulously crafted construction ensure exceptional performance and durability.

- Bright LCD display 320 x 240

- Angle & Tool programming

- CNC Back gauge control

- Developed length calculation

- Up to 25 bends per program

- Servo, frequency inverter and AC control

- The basic machine control functions are Y ,X-axis.

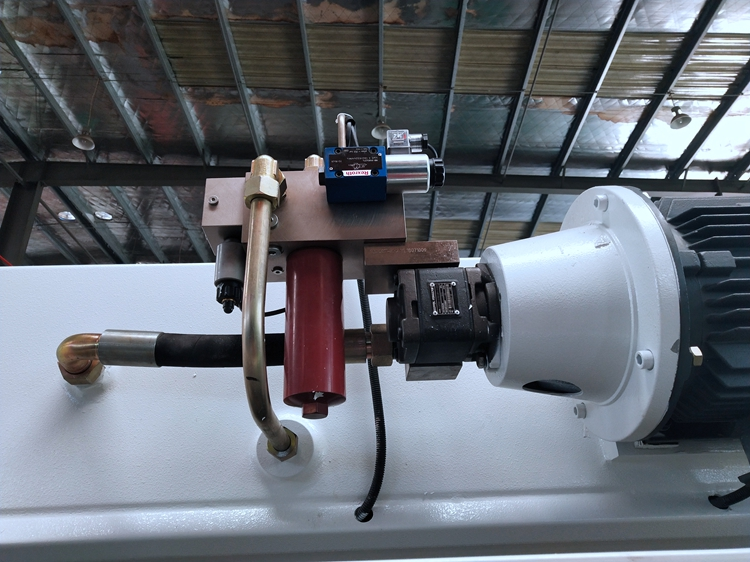

Hydraulic System

This hydraulic control system is compact, powerful, and cost-effective. It has strong anti-eccentric load capabilities, high accuracy synchronization, and a high power density ratio. The hydraulic system pressure can be adjusted as needed to meet bending force requirements. MINNUO has chosen well-known German brand for our efficient and reliable hydraulic system.

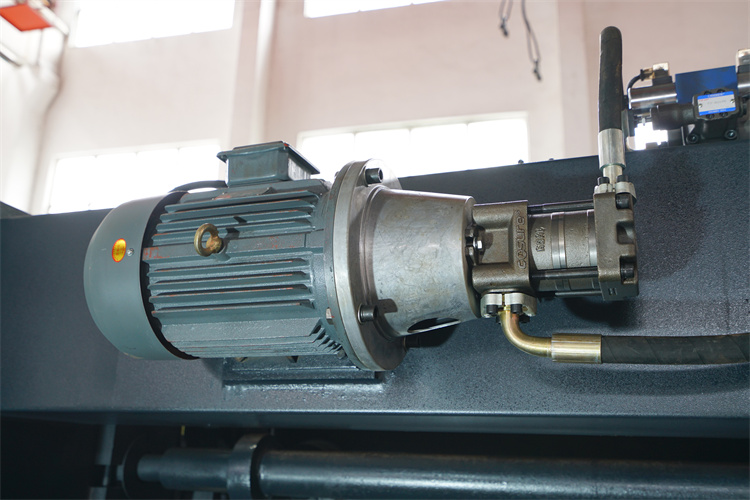

Motor

Servo motors are recognized for high dynamics and energy efficiency, surpassing traditional motors by saving up to 35% energy. We provide a highly efficient motor from Siemens, Germany, offering increased work efficiency for our customers.

Oil Pump

The oil pump from America Sunny is made of durable cast iron and incorporates a special internal noise reduction system. This feature makes it less affected by oil pollution and extends its lifespan.

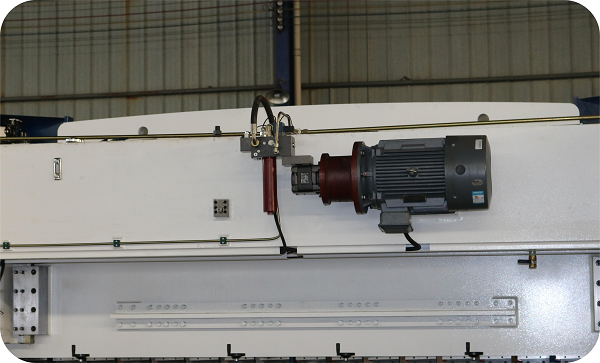

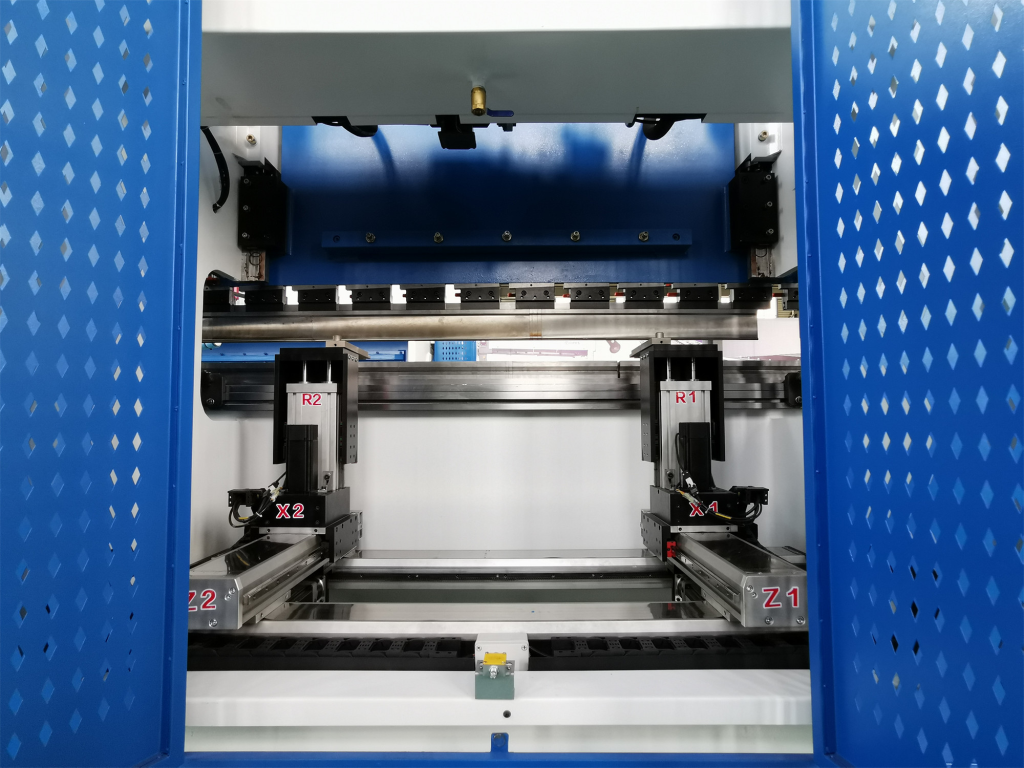

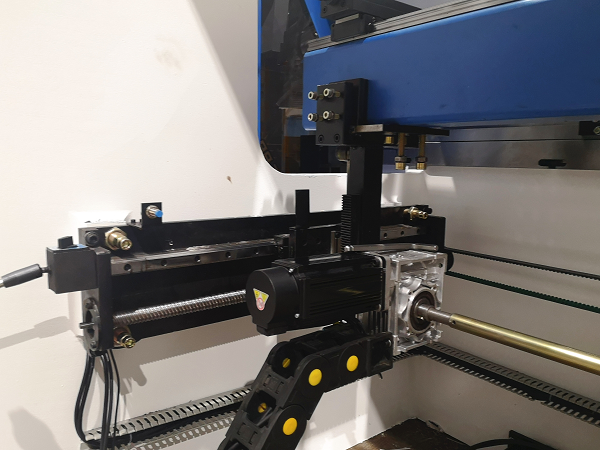

Backgauge

We use imported ball screws and linear guide rails on the X-axis for superior movement accuracy, enhancing precision and consistency in our fabrication process.

Our rear stop is controlled by a servo motor with a synchronous pulley mechanism instead of a stepping motor, ensuring better control and accuracy.

Our backgauge system undergoes high-temperature tempering to eliminate internal stress, improve metal plasticity and toughness, and prevent accuracy loss due to frame deformation.

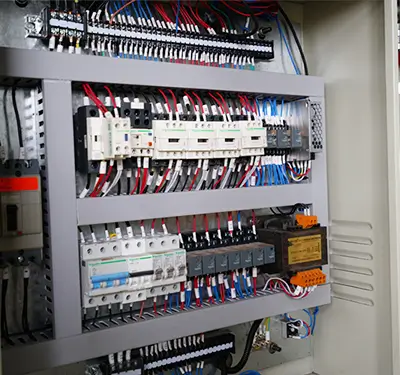

Electrical Parts

The machinery utilizes genuine Schneider components that are imported from France and well-known for their stability, durability, and extended lifespan. Additionally, the machine is equipped with an authentic Estun adaptive electrical box assembly, known for its strong resistance to interference and reliable electrical performance.

Crowning

Utilizing our independently developed system, we accurately determine the compensation value by considering the combined deformation of the ram and worktable. As a result, the bed’s deformation curve seamlessly aligns with the compensation curve, guaranteeing impeccable straightness and angle uniformity in our products.

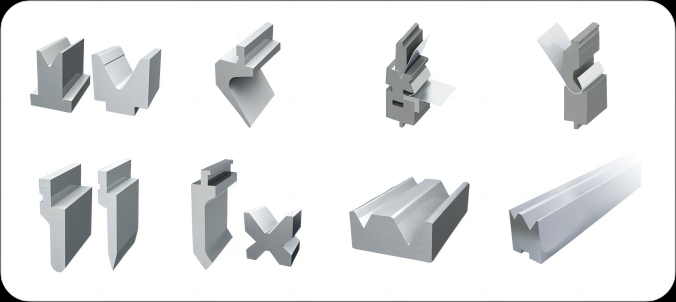

Fast Clamp

Replacing our top punch is a quick and uncomplicated task, enabling us to maximize our time efficiency.

Ball Screw & Guide

The smooth and reliable operation of the machine is ensured by the inclusion of ball screws and linear guide rails.

Servo Motor

Superior accuracy is guaranteed as a servo motor precisely controls the Y-axis movement.

Punches & Dies

Before placing your order, it is important to carefully choose the right press brake punches and dies. The perfect combination of these tools is essential in achieving the exact bending shape you desire. Our selection of tooling options is extensive and designed to meet the unique bending needs of our customers.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com