In today’s world of modern manufacturing, efficiency and precision are key. If you’re exploring advanced machining solutions, understanding 5-axis CNC machines is a must. These machines change the game for how parts are made, reducing setup time and increasing accuracy. Let’s dive into why 5-axis CNC machines are so important.

A 5-axis CNC machine refers to a machine’s ability to move a tool or a part in five different axes at the same time. Unlike traditional 3-axis CNC machines, 5-axis machines can rotate along two additional axes (A and B), giving them a multidirectional approach and making them more accurate and efficient.

Now, let’s take a closer look at what makes 5-axis CNC machines so special and the benefits they provide.

What is a 5 Axis CNC Machine?

A 5-axis CNC machine is an advanced and versatile machining tool that moves a part or tool in five different axes at the same time, making it more accurate and efficient. These machines can create complex parts with high accuracy, often within microns.

History and Trends

To understand the importance and future potential of 5-axis CNC machines, it’s important to look back at their development over the years. This timeline highlights key advancements and trends that have shaped these powerful tools.

- 1960s: The concept of 5-axis machining started to develop, driven primarily by the aerospace industry’s need for complex part geometries.

- 1980s: 5-axis CNC machines started to gain popularity with the advent of more advanced computer technology, allowing for better control and precision.

- 2000s: Integration of CAM (Computer-Aided Manufacturing) software, making programming easier and more efficient.

- 2010s: The incorporation of IoT and AI, leading to smarter and more autonomous machines.

What are the 5 Axis?

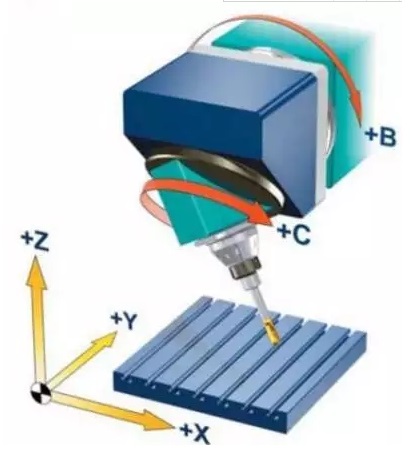

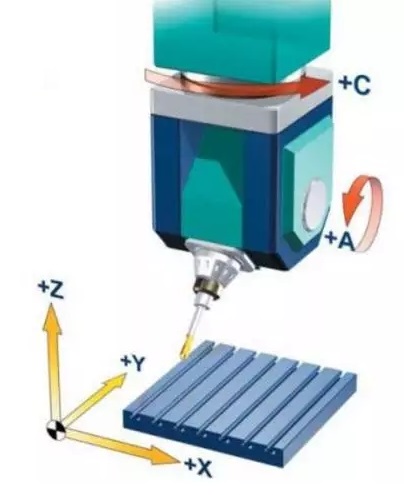

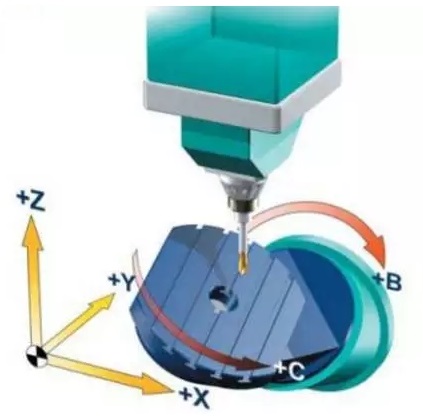

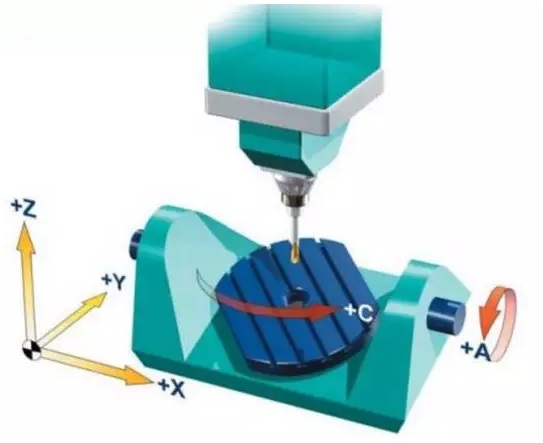

The term “5-axis” refers to a machine’s ability to move a part or tool along five different axes, which is critical for creating complex geometries and achieving precision. Let’s break down each axis and what it does in the machining process.

X-Axis: Moves the cutting tool or part from left to right. This linear axis is important for horizontal movements and sets the foundation for the machining process.

Y-Axis: Moves the cutting tool or part from front to back. It complements the X-axis by adding depth to the machining process.

Z-Axis: Moves the cutting tool or part up and down. This vertical movement is important for adjusting the height and depth of cuts.

A-Axis: Rotates around the X-axis. This rotational axis allows for angled cuts and intricate geometries.

B-Axis: Rotates around the Y-axis. It allows the tool to approach the part from different angles, further enhancing the machine’s ability to handle complex shapes.

How Does a 5 Axis CNC Machine Work?

Understanding how a 5-axis CNC machine operates is key to appreciating what it can do. Here, we’ll explore the synchronization and precision involved in these advanced machines.

These machines work by synchronizing the movement of the cutting tool along the X, Y, Z, A, and B axes. This synchronized movement allows for machining complex geometries without having to manually reposition the part, which is crucial for maintaining high precision. The process involves advanced software and precise calibration to ensure all axes move correctly together.

Types of 5 Axis CNC Machines

5-axis CNC machines are classified based on their configuration and movement capabilities, each type offering unique advantages for different applications. Let’s take a closer look at these types and what they bring to the table.

- Trunnion machines

These have a table that tilts and rotates, providing high rigidity and stability, making them ideal for heavy-duty cutting. The main advantage is the ability to handle larger and heavier workpieces.

- Swivel head machines

The spindle itself moves, giving you more flexibility and the ability to reach complex angles. These machines are great for intricate and detailed work.

- Hybrid machines

Combine elements of both trunnion and swivel head designs, offering a balance of rigidity and flexibility. They are versatile and suitable for a wide range of applications.

Best Applications for 5 Axis CNC Machines

5-axis CNC machines excel in various industries because they can create complex parts with high precision. Here, we’ll look at the most suitable applications and the types of workpieces these machines can handle.

- Aerospace: Manufacturing complex components like turbine blades, wing spars, and engine parts with tight tolerances.

- Automotive: Producing parts such as engine blocks, transmission components, and custom car parts.

- Medical Devices: Creating precise components for implants, surgical instruments, and diagnostic equipment.

- Energy Sector: Making parts for turbines, pumps, and other equipment used in the oil and gas, and renewable energy industries.

- General Manufacturing: Versatile use in creating molds, tools, and custom parts for various industries.

The Advantages of 5 Axis CNC Machines

There are many advantages to using 5-axis CNC machines, from improved efficiency to higher precision. Here are the key benefits that make these machines the preferred choice in modern manufacturing.

Advantages include:

- Reduced setup time: Fewer setups are needed, which saves time and reduces errors.

- Higher precision: Capable of machining with tolerances as tight as 0.001mm.

- Complex parts: Can create parts with intricate geometries.

- Improved surface finishes: Provides excellent finishes by reducing the need for manual finishing.

- Increased productivity: Higher efficiency leads to increased overall productivity.

The Difference Between 3+2 Axis and 5 Axis CNC Machines

Understanding the difference between 3+2 axis and true 5-axis machining is important for understanding their capabilities and applications. Here, we’ll look at the differences and what they mean for manufacturing.

3+2 Axis Machining:

Involves positioning the part using two rotational axes (A and B) and then machining with the three linear axes (X, Y, and Z).

The rotational axes do not move during the cutting process, providing a way to access multiple sides of the part with different setups.

Benefits: Easier programming and setup, suitable for less complex geometries.

True 5-Axis Machining:

All five axes (X, Y, Z, A, and B) move simultaneously during the machining process.

Allows for the creation of highly complex parts in a single setup, reducing the need for repositioning.

Benefits: Higher precision, reduced setup time, and ability to machine intricate details.

The Difference Between 5 Axis and 6 Axis CNC Machines

Understanding the difference between 5-axis and 6-axis CNC machines helps you choose the right tool for your specific manufacturing needs. Here, we’ll compare these two types to highlight their unique features and advantages.

A 6-axis CNC machine adds an additional rotational axis along the Z-axis, providing even greater flexibility and speed in machining complex parts. This additional axis allows for more dynamic and efficient machining operations, particularly beneficial for parts requiring extensive contouring and intricate details.

How Much Does a 5 Axis CNC Machine Cost?

The cost of a 5-axis CNC machine is a significant investment, and understanding the price range and factors that affect it is important for making an informed purchase.

The cost of 5-axis CNC machines varies widely based on features, capabilities, and manufacturer. Entry-level models may start around $100,000, while high-end machines can exceed $500,000. Factors that influence price include machine size, accuracy, additional features like automatic tool changers, and advanced software.

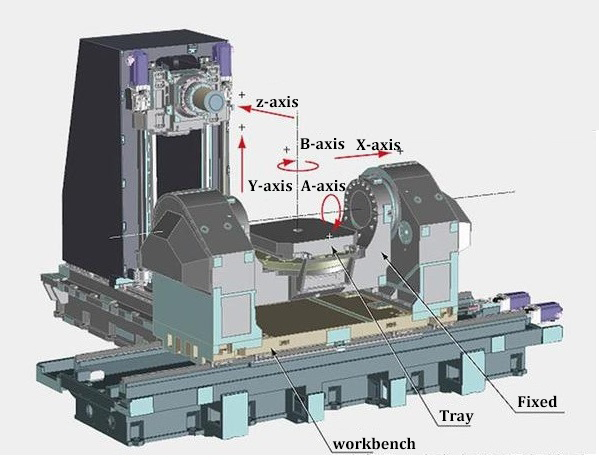

Understanding the 5 Axis CNC Machine Diagram

Understanding the 5-axis CNC machine diagram is important for operators and engineers to effectively use and maintain these machines. Let’s break down the key components and their functions.

A typical 5-axis CNC machine diagram shows the machine’s components, including the spindle, rotary tables, and the various axes. Understanding the diagram helps you understand how each part contributes to the overall machining process and maintenance requirements. Key components include the machine bed, spindle head, tool changer, and control panel.

The Basics of 5 Axis CNC Programming

Effective programming is at the heart of successful 5-axis CNC machining. Here, we’ll cover the basics of programming these machines and the tools you need for precision manufacturing.

Programming a 5-axis CNC machine requires advanced skills and software capable of handling complex movements. G-code is the standard language used, and programmers must consider tool paths, feed rates, and machine limits to optimize efficiency and accuracy. CAD/CAM software is typically used to create and simulate tool paths before actual machining.

How to Choose the Right 5 Axis CNC Machine

Choosing the right 5-axis CNC machine involves considering several factors to match your specific manufacturing needs. Here’s a guide to help you make an informed decision.

When choosing a 5-axis CNC machine, consider factors such as:

- Machine size: Make sure it fits in your workspace and can handle the parts you want to machine.

- Capabilities: Match the machine’s features with your production needs.

- Software compatibility: Make sure it integrates with your existing systems.

- Manufacturer support: Good customer service and maintenance support are important.

- Budget: Balance your requirements with your financial constraints.

Conclusion

Exploring and investing in a 5-axis CNC machine can significantly enhance your manufacturing capabilities. Their ability to handle complex designs with precision and efficiency makes them a worthwhile consideration for serious buyers. Stay informed, compare options, and choose a machine that meets your specific needs.

Minnuo Machinery has a strong capability of manufacturing 5-axis CNC machine tools, and we have exported hundreds of 5-axis CNC machine tools to all over the world. Believe us, you and I work together to win the new era of precision machining! Contact us to get discount price~