CNC routers, or Computer Numerical Control routers, are powerful tools revolutionizing various industries, from woodworking to metal fabrication and beyond. With the ability to carve, cut, and shape materials with incredible precision, CNC routers have become indispensable for professionals and hobbyists alike.

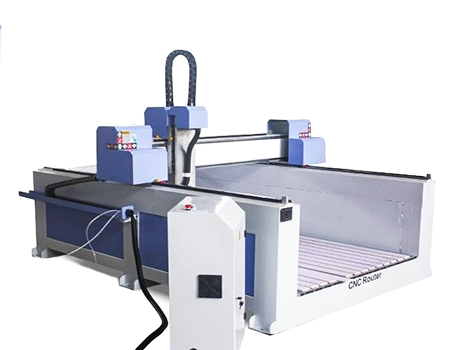

A CNC router is a computer-controlled cutting machine used for carving, engraving, and shaping a wide variety of materials, including wood, metal, plastic, and foam. It operates with high precision, following programmed instructions (G-code) to produce intricate designs and parts quickly and efficiently. CNC routers are widely used in industries like woodworking, metalworking, and sign-making for their ability to automate complex tasks, improve accuracy, and reduce waste.

Whether you are looking to enhance your manufacturing capabilities or explore creative endeavors, understanding CNC routers is key to unlocking their full potential.

What is a CNC Router?

A CNC router, or Computer Numerical Control router, is a cutting machine controlled by a computer. Unlike manual routers, which require hands-on operation, CNC routers use a series of programmed instructions, known as G-code, to guide the machine’s movements and operations. This automation allows for consistent, precise cuts, making CNC routers ideal for producing detailed parts and intricate designs across various materials.

History and Evolution of CNC Routers

The journey of CNC routers began in the 1940s with the advent of numerical control (NC) machines. These early machines relied on punched tape to control their movements. However, the technology quickly evolved. By the 1970s, the integration of computers into machining led to the development of CNC technology, revolutionizing manufacturing. Today, CNC routers are more advanced than ever, equipped with sophisticated software, high-speed spindles, and multi-axis capabilities.

Components of a CNC Router

A CNC router comprises several key components, each playing a vital role in its operation:

- Router Spindle: The heart of the CNC router, the spindle holds the cutting tool and rotates at high speeds, ranging from 10,000 to 24,000 RPM. The choice of spindle depends on the material and the desired precision.

- Worktable: The surface on which the material rests. Worktables can be fixed or movable, with vacuum tables being a popular choice for their ability to hold materials securely during operation.

- Control System: The brain of the CNC router, consisting of hardware and software that interpret G-code and direct the machine’s movements.

- Drive System: Responsible for moving the router along the X, Y, and Z axes, the drive system typically uses stepper motors or servo motors. Stepper motors offer precision, while servo motors provide speed and power.

- Axis and Movement: CNC routers typically operate on three axis (X, Y, and Z), but advanced models can have additional axis for more complex movements.

- Tooling and Accessories: Various cutting tools, bits, and accessories are used depending on the material and desired outcome.

Types of CNC Routers

CNC routers come in various types, each suited to different applications:

Hobbyist CNC Routers

Designed for DIY enthusiasts and small projects, these routers are typically more affordable and compact but offer less power and precision than industrial models.

Industrial CNC Routers

Built for heavy-duty use, industrial routers are robust, powerful, and capable of handling large volumes of work with high precision.

3-Axis vs. 4-Axis vs. 5-Axis Routers

The number of axes determines the router’s ability to move and rotate, with more axes allowing for more complex cuts and shapes.

Desktop CNC Routers

Ideal for small-scale work, these routers are compact and perfect for workshops with limited space.

Large-Format CNC Routers

Used for large projects, these routers can handle large sheets of material, making them ideal for sign-making and cabinetry.

Specialized CNC Routers

Designed for specific materials like wood, metal, foam, or stone, these routers are optimized for particular applications.

Materials That Can Be Cut on a CNC Router

CNC routers are versatile machines that can cut a wide range of materials:

- Wood: Softwoods like pine, hardwoods like oak, and plywood are commonly used. CNC routers are perfect for creating furniture, cabinetry, and decorative pieces.

- Metals: Aluminum, brass, and mild steel can be precisely cut, drilled, and engraved using CNC routers, making them valuable in metalworking and prototyping.

- Plastics: Materials such as acrylic, PVC, and polycarbonate are ideal for CNC routing, often used in signage and parts production.

- Foam: High-density foam and expanded polystyrene (EPS) are used in packaging, insulation, and prototyping.

- Composite Materials: Carbon fiber and fiberglass are often cut with CNC routers in industries requiring lightweight, strong materials, such as automotive and aerospace.

- Stone and Ceramics: CNC routers can cut stone, marble, and ceramics, but these require specialized bits and slower feed rates to avoid damaging the material.

Applications of CNC Routers

CNC routers have a wide array of applications across different industries:

- Woodworking: Creating custom furniture, cabinetry, and intricate wood carvings.

- Metalworking: Cutting and shaping metal parts, molds, and prototypes.

- Signage: Producing 2D and 3D signs for commercial and decorative purposes.

- Prototyping: Rapidly creating prototypes for testing and development in various industries.

- Arts and Crafts: Crafting unique designs and art installations from various materials.

- Aerospace and Automotive: Manufacturing parts and components with high precision.

Advantages of Using CNC Routers

The advantages of CNC routers are numerous:

- Precision and Accuracy: Achieving detailed and accurate cuts, ensuring consistency across multiple parts.

- Efficiency and Speed: Automated cutting processes reduce production time and labor costs.

- Versatility: Capable of working with various materials, CNC routers offer flexibility in manufacturing.

- Automation: Minimal manual intervention reduces errors and increases safety.

- Cost-Effectiveness: Efficient use of materials and reduced waste contribute to lower production costs.

Disadvantages and Limitations of CNC Routers

- While CNC routers are highly beneficial, they also have some drawbacks:

- High Initial Cost: The investment in CNC machinery and software can be substantial.

- Learning Curve: Operating CNC routers requires knowledge of CAD/CAM software and CNC programming.

- Maintenance: Regular maintenance is necessary to keep the machines running smoothly.

- Material Limitations: Some materials, like hard metals or delicate ceramics, may require specialized routers or tools.

Common Mistakes to Avoid in CNC Routing

Avoiding common mistakes can help maximize the efficiency and longevity of CNC routers:

Improper Tool Selection

Using the wrong tool for a material can result in poor-quality cuts and damage to the router.

Incorrect Feed and Speed Settings

Setting incorrect speeds can cause tool wear and tear, material burning, or breakage.

Lack of Maintenance

Neglecting routine maintenance can lead to malfunctions and costly repairs.

Ignoring Safety Protocols

Not following safety guidelines can result in accidents and injuries.

Poor File Preparation

Errors in CAD/CAM files can lead to incorrect cuts and wasted materials.

How to Choose the Right CNC Router

Selecting the right CNC router depends on several factors:

- Purpose and Application: Define what you intend to create and choose a router that meets those needs.

- Budget Considerations: Determine your budget and find a router that offers the best value within that range.

- Material Compatibility: Ensure the router is capable of cutting the materials you plan to use.

- Size and Workspace: Consider the available space in your workshop and choose a router that fits.

- Software Compatibility: Check that the CNC router is compatible with your preferred CAD/CAM software.

- Customer Support and Warranty: Good after-sales service and a robust warranty are essential for long-term satisfaction.

CNC Router vs. Other Machine Tools

Comparing CNC routers with other machine tools can help determine which is best for your needs:

CNC Router vs. CNC Milling Machine

While both are used for cutting materials, routers are generally faster and better suited for softer materials, whereas milling machines are more robust and suitable for harder metals.

CNC Router vs. Laser Cutter

Laser cutters offer higher precision and can cut through tougher materials, but CNC routers are more versatile in terms of material compatibility.

3D Printer vs. CNC Router

CNC routers remove material to create shapes, while 3D printers add material layer by layer. CNC routers are better for creating parts from solid materials, while 3D printers excel in rapid prototyping with plastic materials.

Waterjet Cutter vs. CNC Router

Waterjet cutters use a high-pressure stream of water to cut materials and can cut through almost anything without heat distortion, but CNC routers are faster and more economical for certain applications.

CNC Router Maintenance

Regular maintenance is crucial for ensuring the longevity and optimal performance of CNC routers:

- Daily Maintenance: Clean the worktable, check the lubrication system, and inspect tools

- for wear and damage.

- Weekly and Monthly Checks: Perform thorough inspections of the drive system, check software updates, and calibrate the machine.

- Long-Term Maintenance: Replace worn-out parts, update software, and ensure all components are functioning correctly.

- Troubleshooting Common Issues: Address common problems such as tool breakage, poor cut quality, and software errors promptly to avoid further damage.

Cost Analysis of CNC Routers

Understanding the cost associated with CNC routers helps in making informed decisions:

- Initial Investment: CNC routers can range from a few thousand to several hundred thousand dollars, depending on size, features, and capabilities.

- Operating Costs: These include electricity, tooling, and maintenance, which vary based on usage and the complexity of projects.

- Training Costs: Proper training on operating CNC routers and software can prevent costly mistakes and improve efficiency.

- ROI Considerations: Evaluate the return on investment by considering the cost savings from reduced labor, increased production speed, and material efficiency.

Future Trends in CNC Routing Technology

The future of CNC routing technology looks promising with several advancements on the horizon:

Automation and Robotics: Integration of robotics for handling materials and assembling parts.

AI and Machine Learning: Smart systems for predictive maintenance and optimized routing paths.

Material Innovations: New materials like advanced composites and ceramics for cutting-edge applications.

Hybrid Machines: Combining CNC routing with other manufacturing processes for greater versatility and efficiency.

Conclusion

In today’s article, we delved into the world of CNC routers, exploring their fundamental principles, components, and diverse applications. CNC routers, controlled by computer systems, offer precise and efficient cutting capabilities across a range of materials, including wood, metal, plastic, and foam. We discussed their evolution from early numerical control machines to modern, high-tech devices, and highlighted the various types of CNC routers available, from hobbyist models to industrial-grade machines.

FAQs

Is a CNC router suitable for home use?

Yes, there are hobbyist and desktop CNC routers designed for home use. They are typically smaller, more affordable, and suitable for light-duty projects.

What industries benefit most from using CNC routers?

Industries such as woodworking, metalworking, sign-making, automotive, aerospace, and arts and crafts benefit significantly from the precision, efficiency, and versatility of CNC routers.