Flexible manufacturing cell improves production efficiency and quality, reduces cost and risk of errors, enhances production line flexibility and competitiveness, and monitors production data in real time. In the future, flexible manufacturing cells will be more intelligent, automated and flexible, promoting digital transformation and intelligent upgrading of the manufacturing industry.

Brief flexible manufacturing cell

Flexible manufacturing is a kind of new production mode for mass customization. It can quickly adapt to changes in market demand, product design updates and changes in the manufacturing process. Flexible manufacturing emphasizes adaptability and flexibility in the production process. Its core advantages, high customization and excellent adaptability, enable it to effectively meet mass customization needs.

With the rise of Industry 4.0, flexible manufacturing is becoming an important trend in manufacturing industry. Industrial Internet, Robot Technology and artificial intelligence have changed the production and management mode of traditional industry, and made the flexible production mode of“Individual customization” and“One-piece-order” become reality.

Flexible manufacturing system (FMS) refers to a transmission system linking equipment to convey workpieces to processing equipment, ensuring accurate, rapid, and automated processing. Flexible manufacturing systems have central computer-controlled machine tools and transmission systems that sometimes process several different parts simultaneously.

Automatic handling and conveying machines connect a group of sequential machines, while a computer system integrates the process. Operators load and unload raw materials and machining parts onto a part-conveying system. The parts undergo processing on one machine before being transferred to the next machine. Each machine accepts the operation instruction and automatically loads and unloads the required tools without human involvement.

Origins

In 1976, the FMC, a flexible manufacturing unit consisting of a machining center and an industrial robot, was exhibited by the Japanese company Fanako, FMS is a product of the development of cheap and miniaturized FMS. Flexible manufacturing unit refers to one or several CNC machine tools or machining centers constitute a machining unit, the unit according to the need for automatic replacement of tools and fixtures, processing different workpieces. Flexible manufacturing cell is suitable for processing complex shapes, simple machining processes, long machining time, small batch parts.

Principle

Facing the demand of product individuation and the rising cost of manufacture, it is always the request of manufacturers to improve the flexibility of production. The FMC actually extends from the NC Machining Center, comprising a machining center and an industrial robot, both controlled by a programmable logic controller.

Importance

Flexible manufacturing cells (FMC) are critical to modern manufacturing, primarily because they increase production efficiency, reduce costs, and increase responsiveness to market changes through high levels of automation and adaptability. It supports small-batch, multi-variety, high-efficiency production, meets personalized customization needs, improves product quality, and reduces waste by optimizing resource allocation. FMC is a key technology adapting to industry 4.0 and smart manufacturing trends, which can enhance the market competitiveness of enterprises and promote technological innovation.

Flexible manufacturing cells composition

1. A machine consisting of a machining center or a mixture of CNC machines (including CNC machines) . FMCs typically include up to four turning units for rotating parts and predominantly utilize machining centers for non-rotating part processing.

2. Automated parts transportation, exchange, and storage facilities within the unit. Based on workpiece traits and in-unit transfer methods, there are two primary workpiece delivery approaches in the unit.

1) The transport mode of Pallet. Suitable for processing box or non-rotating parts of the FMC. For easier workpiece handling and clamping, operators secure the workpiece to the support plate. Specific equipment includes a pallet conveyor, a pallet repository, and an automatic pallet exchange.

2) Direct delivery. FMC for rotating parts. The robot or manipulator transports the workpiece directly to the CNC lathe, CNC grinder, or turning center for clamping. Adjacent to the machine tool is a hopper for storing blanks or workpieces. For external system interaction, FMC uses pallet exchange, with the workpiece and pallet conveyed by external equipment like car input units or self-unit outputs.

3. Information Flow System. This system realizes the processing, storage and transmission of information during processing.

The basic form of a flexible manufacturing cell

- Ring pallet library FMC

- FMC features a circular pallet layout, with a dedicated device transferring pallets between loading/unloading stations and machine tool pallets.

- The straight-line FMC, a linear version of the circular FMC, typically uses a trolley as its carrier conveyance device. FMC’s benefit is their expandability, easily growing with extra equipment and transport systems to meet needs.

- Robotic handling FMC

- A gyrobot directly carries the FMC. It comprises 1 to 4 turning centers or other CNC machine tools, along with fixed rotary robots and workpiece storage tables. All equipment is arranged around or on both sides of the robot. During the machining process, the robot automatically carries the workpiece. This type of FMC has the advantage of being equipped with a support plate and an automatic exchange system, resulting in low equipment costs. However, it is only suitable for processing rotary parts.

- A gantry-type robot carries the FMC directly. The FMC of gantry-type robot is characterized by being able to carry larger and heavier parts and other materials without taking up space.

- Replaceable spindle box type FMC

This unit primarily undertakes multi-axis processing, catering to a moderate variety of medium to large-scale production. It features a replaceable spindle box on the combined machine tool, along with a spindle library and its transport exchange device. Entering the unit via the pallet exchange, the workpiece is transported to and clamped on the circular rotary table. Subsequently, it undergoes processing by the power head equipped with the corresponding spindle box on both sides.

The replaceable spindle box predominantly comprises multi-spindle configurations, offering heightened processing efficiency compared to conventional single-spindle processing centers. However, the targeted spindle configuration of the multi-spindle box limits flexibility. Nonetheless, the unit compensates for this limitation through the headstock stock, which stores various headstocks for several parts awaiting processing. This feature ensures the unit’s adaptability, enabling the mixing of multiple parts within the FMC.

The characteristics and advantages of flexible manufacturing cells

- Flexibility: can quickly adapt to different products, different processes of production needs, to achieve rapid line change, rapid production.

- Reconfigurable: can quickly reconfigure equipment, process and process according to production needs to achieve rapid reconfiguration of the production line.

- High degree of automation: adopt Advanced Automation Technology, reduce manual intervention, improve production efficiency and product quality.

- Intelligent Management: through the intelligent control system, the real-time monitoring, data analysis and optimization of the production process decision-making.

- Technical and economic benefits: increased the flexibility of the processing process, can achieve 24-hour uninterrupted processing, with significant economic benefits.

Application of flexible manufacturing cell

Flexible manufacturing units, utilized across machinery, automotive, electronics, and more, offer adaptable, high-efficiency production solutions to businesses. Using FMCs, companies swiftly adapt to market changes, enhancing production efficiency and quality while cutting costs and inventory expenses.

As a manufacturing industry tool, the Flexible Manufacturing Cell (FMC) helps companies adapt to market shifts, boosting efficiency and product quality. With the development of technology and manufacturing industry, FMC will play a more important role in the future.

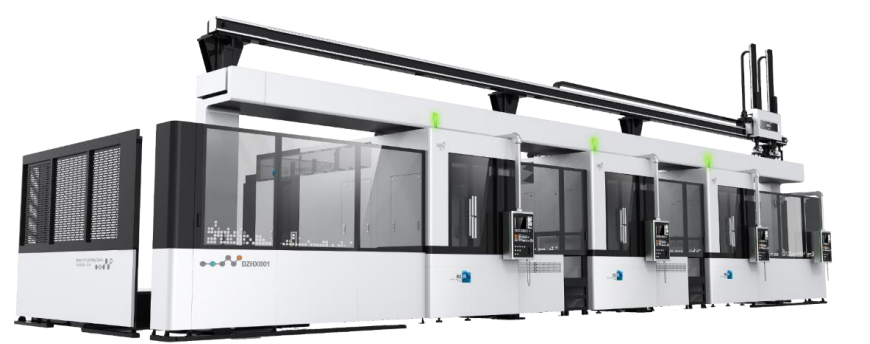

The pioneer of Minnuo flexible manufacturing system

Minnuo, as a pioneer in flexible systems, has already had several projects applied to real manufacturing industries. Our horizontal machining centers FMC4008 and FMC5008 are very good at realizing flexible manufacturing, widely used in automobile, mold, machinery manufacturing and other industries box parts, shell parts, disk parts, abnormal parts processing, it is designed to meet the needs of modern manufacturing for efficient, low-cost and high-quality production. Our FMC adopts the most advanced technology, not only can adapt to multi-species, small and medium batch production environment, but also can achieve continuous production without downtime, greatly improving production efficiency. More importantly, our FMC can ensure product quality consistency and reliability, for your enterprise to enhance market competitiveness. To choose minnows is to choose professionalism, efficiency and reliability. Let’s work together for a better future!