Understanding what a lathe is and choosing the right one can be confusing. With so many different types and uses, beginners and buyers often feel overwhelmed. In this guide, I’ll explain what a lathe is, its uses, the different types, and provide a buying guide to help you understand and purchase a lathe more effectively.

Lathe is a machine tool used for machining rotating workpieces. It performs cutting, grinding, drilling, and other operations by rotating the workpiece and employing various cutting tools. Lathes are widely used in the manufacturing industry, capable of efficiently and precisely producing cylindrical, conical, and other complex-shaped parts.

Curious about what a lathe is and how it can benefit you? Dive into my comprehensive guide for beginners and discover the world of lathes!

What Is a Lathe?

A lathe is a machine tool that rotates a workpiece to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading, and turning. It is an essential tool in manufacturing and repair processes. By rotating the workpiece and moving a fixed cutting tool along a specific path, the lathe removes material to shape the workpiece into the desired form.

The History of the Lathe

The lathe has been around since ancient Egypt when early lathes were powered by hand or foot. Here are some key milestones in the development of the lathe:

1300 BC: Ancient Egyptians used simple hand-operated lathes to shape wood.

1st Century AD: Romans improved lathe technology by introducing foot-powered lathes, which increased efficiency.

1797: Henry Maudslay invented the screw-cutting lathe in England, which was the precursor to modern lathes and allowed for precise screw threads.

Late 19th Century: The introduction of electric motors greatly improved lathe efficiency and precision.

1950s: CNC (Computer Numerical Control) technology brought automation and high precision to lathe operations.

21st Century: Lathes continue to evolve with more sensors and AI technology, which enhance automation and precision.

The Main Parts of a Lathe

A lathe consists of several main parts, each with a specific function:

Bed: This supports and stabilizes the entire structure of the lathe.

Headstock: This contains the spindle, which provides the rotational power for the workpiece.

Tailstock: This supports long workpieces and adds additional stability during machining.

Carriage: This holds and controls the movement of the cutting tool.

Feed Mechanism: This controls the relative motion between the cutting tool and the workpiece.

Control System: Modern lathes typically have CNC systems, which enhance precision and efficiency.

How a Lathe Works

A lathe works by rotating a workpiece and moving a fixed cutting tool along a predetermined path to remove material. The main operations include turning, facing, drilling, and threading. By adjusting the position of the tool and the feed rate, you can achieve precise material removal and surface finishing.

Types of Lathes

Lathes come in a variety of types, each designed for specific functions:

Engine Lathe

Good for basic machining tasks, simple in structure, and flexible in operation.

CNC Lathe

Equipped with computer numerical control, great for high-precision and complex shapes. Highly automated and efficient.

Turret Lathe

Has multiple tool holders for quick tool changes, great for mass production.

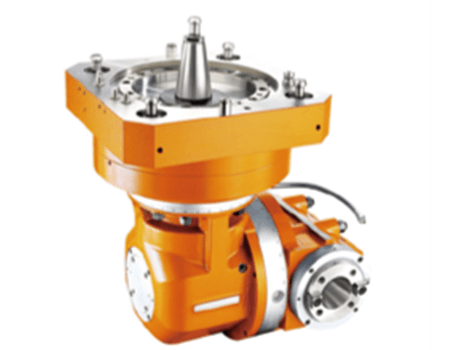

Turning Center

Combines turning with other machining operations like milling and drilling, great for complex parts.

Horizontal Lathe

Workpiece mounts horizontally, great for long workpieces.

Vertical Lathe

Workpiece mounts vertically, great for large-diameter workpieces.

Precision Lathe

Designed for high-precision work on small parts.

Combination Lathe

Combines lathe and other machine tool functions like milling, great for multifunctional machining needs.

Toolroom Lathe

Used for precision work and often found in tool rooms for manufacturing fixtures and tooling.

Gap-Bed Lathe

These lathes have a section of the bed that can be removed to accommodate larger diameter workpieces.

Swiss Lathe

Known for its high precision, used for small, complex parts often required in the medical and electronics industries.

Materials Machined by Lathes

Lathes can machine a variety of materials, including:

Metals: Common metals include steel, aluminum, copper, brass, and stainless steel. Steel is widely used for heavy machinery and automotive parts due to its strength and durability. Aluminum, with its lightweight and corrosion resistance, is often used in aerospace and electronics. Copper and brass, known for their conductivity and corrosion resistance, are used in electrical and plumbing fittings. Stainless steel is great for environments requiring high strength and corrosion resistance, such as medical instruments and food processing equipment.

Wood: Often used in furniture making, decorative items, and musical instruments. Different types of wood, such as hardwood and softwood, can be finely carved and cut on a lathe.

Plastics: Common plastics include ABS, PVC, nylon, and acrylic. Plastics are widely used in electronic enclosures, medical devices, and model making due to their ease of machining and lightweight properties.

Composites: Materials like fiberglass and carbon fiber are strong and lightweight, commonly used in aerospace, automotive, and sports equipment.

Lathe applications

Lathes are used in a wide range of industries, including:

- Manufacturing: Lathes are used to make things like shafts, round parts, and precision parts like gears, bearings, and bolts.

- Automotive: Lathes are used to make things like crankshafts, camshafts, transmission parts, and axles.

- Aerospace: Lathes are used to make high-precision parts for airplane engines and airplane structures to make sure they are reliable.

- Furniture Making: Woodturning lathes are used to make decorative and functional parts for furniture like table legs, chair backs, and railings to make them look good and work well.

- Medical: Lathes are used to make precision parts for medical devices and instruments like surgical tools and implants to make sure they are accurate and high quality.

- Electronics: Lathes are used to make plastic and metal boxes, connectors, and other components for electronics.

- Oil and Gas: Lathes are used to make things like pipes, flanges, and other parts that are important for drilling and pipelines.

- Jewelry Making: Lathes are used to make intricate designs and parts for jewelry.

- Textiles: Lathes are used to make parts for machines that make textiles.

Advantages and Disadvantages of Lathes

Advantages

Lathes are very precise and can make a lot of different shapes and sizes of things. CNC lathes are especially good for making things that are complicated and need to be very precise.

Disadvantages

Lathes are hard to use and you need to know what you are doing. They can also be expensive to buy and use. Some lathes are more expensive and need special skills to use.

How to Use a Lathe

To use a lathe, do the following:

- Get the thing you are going to work on ready. Make sure it is the right size and shape.

- Put the thing you are going to work on in the lathe and make sure it is tight and won’t move.

- Get the tool you are going to use and put it in the right place on the lathe.

- Set the lathe to go the right speed and move the right way to make the thing you want.

- Turn on the lathe and make the thing you want to make.

How to Take Care of a Lathe

To take care of a lathe, do the following:

- Clean the lathe so there is no dirt or chips.

- Put oil on the parts that need it like the spindle and the ways.

- Look at the lathe to make sure it is working right. Check the wires and the switches.

- Change the tools and parts that are worn out so the lathe works right and makes good things.

- Make sure the lathe is set right so it makes things that are the right size and shape.

- Make sure the liquid that cools the lathe is right and does not get too hot and wear out the tools.

How Much Do Lathes Cost?

The price of a lathe can vary greatly depending on the type and specifications. You can find lathes for a few thousand dollars all the way up to hundreds of thousands of dollars. The price depends on the brand, model, features, and accessories. You need to choose a lathe that fits your needs and your budget.

How to Choose the Right Lathe

When choosing a lathe, you need to consider your machining needs, your budget, the space you have available, and your level of expertise. You should buy from a reputable brand and a reliable supplier that can provide you with after-sales service and technical support. Here are some tips for choosing the right lathe:

Identify Your Needs: Determine what type of machining you need to do and what level of complexity you need from your lathe.

Consider Your Budget: Choose a lathe that fits your budget. You need to balance the cost of the lathe with the features you need.

Evaluate Your Space: Make sure the lathe you choose will fit in your space. You don’t want to buy a lathe that is too big for your shop or too small for your needs.

Get Technical Support: Choose a brand and a supplier that will provide you with good after-sales service and technical support.

Think About the Future: Consider whether the lathe you choose can be upgraded or expanded with additional features as your needs change.

Train Your Operators: Make sure you have a plan to train your operators on the specific lathe you choose.

The Future of Lathes

The future of lathes is going to be more automation, more intelligence, and higher precision. We will see more sensors and more artificial intelligence (AI) technology in lathes to improve efficiency and quality. Here are some trends to watch for:

More Automation: There will be more use of automatic tool changers and automatic feeders to increase production efficiency.

More Intelligence: AI algorithms will optimize machining paths and parameter settings.

Higher Precision: Advanced control and measurement technologies will allow for higher precision machining.

More Sustainability: We will see the development of more eco-friendly lathes that produce less waste and use less energy.

Remote Monitoring: We will see more integration of the Internet of Things (IoT) for remote monitoring and maintenance. This will allow for real-time tracking of performance and predictive maintenance.

Conclusion

Lathes are a critical tool in modern manufacturing because they are versatile and they can produce very precise parts. They are used in many different industries. I hope this guide has given you a good overview of lathes and has helped you choose the right lathe for your needs.

Frequently Asked Questions

Do they still use lathes today?

Yes, lathes are used in many industries, including woodworking and metalworking.

What kind of lathe do they use the most?

They use engine lathes and CNC lathes the most.

What do they do on a lathe?

They turn, face, drill, and thread on a lathe.