G-code is the lifeblood of CNC machining and 3D printing, guiding machines with precision. To fully grasp the importance of G-code, it’s essential to explore its basic commands, functions, and practical applications in various manufacturing environments.

G-code is a programming language used extensively in CNC machining and 3D printing to control automated machine tools. G-code commands, such as G00 for rapid movements and G01 for linear feed, are fundamental to creating accurate parts and prototypes. Understanding these commands and their applications is essential for optimizing production processes and achieving high-quality results.

This guide delves deep into G-code, unraveling its complexities and practical applications.

What is G Code?

G-code is the universal language for CNC machines, converting digital designs into tangible products. This section provides a foundational understanding of what G-code is and why it’s crucial in the manufacturing industry.

G-code, also known as geometric code, is a standard programming language for CNC (Computer Numerical Control) machines and 3D printers. It provides precise instructions for machine movements and functions, ensuring accurate and efficient manufacturing processes. Each G-code command corresponds to a specific action, such as moving to a coordinate, cutting material, or changing tools. This language is indispensable in modern manufacturing for its ability to translate digital designs into physical products with high precision.

The History and Evolution of G Code

The journey of G-code from its inception to its current role in advanced manufacturing is fascinating. Understanding its history helps appreciate its evolution and capabilities.

G-code originated in the 1950s as part of a project at the MIT Servomechanisms Laboratory. Initially developed to automate and simplify the process of guiding CNC machines, it replaced manual operations with automated precision. Over the decades, G-code has evolved significantly, incorporating advancements in computing and manufacturing technologies. Today, it remains the most widely used CNC programming language, continuously adapting to new machining techniques and applications.

Understanding G Code Commands

G-code commands are the building blocks of CNC programming. Let’s explore the essential commands that guide machine operations.

Basic G-code commands include:

- G00: Rapid move to a specific coordinate position.

- G01: Linear feed move, used for cutting operations.

- G02/G03: Clockwise/counterclockwise feed move for creating arcs.

Each command serves a specific function in CNC programming. For instance, G00 moves the tool quickly to a new position without cutting, while G01 moves the tool in a straight line at a controlled speed, enabling precise cutting. G02 and G03 commands are used for creating circular paths, essential for machining rounded parts.

How G Code Works in CNC Machining

G-code serves as the instruction manual for CNC machines, detailing every movement and operation. This section explains how these machines interpret and execute G-code instructions.

In CNC machining, G-code is interpreted by the machine’s controller, which activates the appropriate motors and tools based on the commands. Each line of G-code consists of a command (such as G01), followed by parameters that specify coordinates (X, Y, Z) and other settings (F for feed rate, S for spindle speed). The controller reads these commands sequentially, executing each one to perform tasks such as moving the tool to a specific location, starting the spindle, or changing tools. This process ensures that the machine operates with high precision and efficiency.

What Are the Types of G-Code?

Different types of G-code commands serve various functions in CNC programming. Understanding these types helps in better utilizing G-code for specific applications.

G-code commands can be categorized into several types:

Motion Commands:

- G00 (Rapid Move): Moves the tool quickly to a specified location without cutting.

- G01 (Linear Feed): Moves the tool in a straight line while cutting at a specified feed rate.

- G02/G03 (Circular Interpolation Clockwise/Counterclockwise): Moves the tool along a circular path.

Plane Selection Commands:

- G17: Selects the XY plane for circular interpolation.

- G18: Selects the ZX plane for circular interpolation.

- G19: Selects the YZ plane for circular interpolation.

Spindle Control Commands:

- M03: Starts the spindle turning clockwise.

- M04: Starts the spindle turning counterclockwise.

- M05: Stops the spindle.

Coolant Control Commands:

- M07: Turns on mist coolant.

- M08: Turns on flood coolant.

- M09: Turns off all coolant.

Units and Modes Commands:

- G20: Sets units to inches.

- G21: Sets units to millimeters.

- G90: Sets absolute positioning mode.

- G91: Sets incremental positioning mode.

Each type of command plays a crucial role in CNC machining, ensuring that the machine operates precisely according to the programmed instructions.

The Importance of G Code

G-code plays a critical role in modern manufacturing, enhancing precision and efficiency. Understanding its importance can lead to better application and optimization of manufacturing processes.

G-code is vital for improving manufacturing precision and efficiency. It allows engineers and operators to control every step of the machine’s operation accurately, leading to consistent and precise product manufacturing. In industries such as automotive, aerospace, medical, and electronics, G-code is essential for creating high-quality components. Furthermore, G-code significantly impacts the development of modern manufacturing technologies by enhancing automation and production efficiency.

Who Needs to Understand G Code?

While G-code is a specialized skill, it is essential for various professionals in the manufacturing industry. Here’s why understanding G-code is crucial for these roles.

Understanding G-code is essential for:

- CNC Engineers and Machinists:

To program and operate CNC machines effectively.

- 3D Printing Specialists:

To ensure accurate and precise printing.

- Manufacturing Process Engineers:

To optimize production processes.

- Educators and Students:

In technical fields to teach and learn advanced manufacturing techniques.

Each of these roles relies on a deep understanding of G-code to perform tasks accurately and efficiently, making it a critical skill in the manufacturing industry.

Applications of G Code in Various Industries

G-code’s versatility allows it to be used across multiple industries, each benefiting from its precision and efficiency. Let’s explore these practical applications.

- Automotive Industry:

Used for precision machining of engine parts, transmission components, and other critical parts.

- Aerospace Industry:

Ensures the accurate production of complex parts for aircraft and spacecraft, meeting strict tolerances.

- Medical Industry:

Used to create medical devices and implants with high precision, improving patient outcomes.

- Electronics Industry:

Guides machines in the production of intricate circuit boards and electronic components.

These applications highlight the importance of G-code in producing high-quality, reliable components across various industries.

Major G Code Simulator Providers

Using G-code simulators can help engineers and machinists test and verify their programs before actual operation. Here are some major G-code simulator providers.

Major G-code simulator providers include:

CNC Simulator Pro: Provides a realistic CNC simulation environment, supporting various types of machines.

NC Viewer: An online G-code viewer and simulator for quick code checks.

CAMotics: Open-source 3D CNC simulation software supporting multiple file formats and operating systems.

Choosing the right simulator can help users identify and resolve potential issues before actual machine operation, improving efficiency and accuracy.

G-code and M-code often work together in CNC programming, but they serve different functions. Understanding their differences is key to effective CNC programming.

G-code and M-code have distinct roles in CNC programming:

- G-code (Geometric Code): Controls the movements and functions of the machine, such as positioning and cutting.

- M-code (Miscellaneous Code): Manages auxiliary functions like starting and stopping the spindle, coolant control, and tool changes.

For example, G01 X10 Y20 moves the tool to coordinates X10, Y20, while M03 starts the spindle. Both codes are essential for comprehensive CNC machine operation.

How to Read and Write G Code

Mastering G-code involves learning how to read and write its commands accurately. This section provides a step-by-step guide to help you get started.

Reading G-Code: Begin by understanding the structure of a G-code command, which typically includes a command letter followed by parameters. For example, G01 X10 Y20 F150 moves the tool to coordinates X10, Y20 at a feed rate of 150 units per minute.

Writing G-Code: Start with basic commands and gradually incorporate more complex instructions. Practice writing simple programs and using CAM software to generate and test G-code.

Practical Tips: Use simulation tools to test your code, ensure correct syntax, and regularly review CNC machine manuals for specific commands and parameters.

In-depth Tutorial on Writing G-Code:

Linear Interpolation (G01) Example:

Code: G01 X50 Y50 Z-1 F100

Explanation: This command moves the tool to the coordinates (X50, Y50, Z-1) at a feed rate of 100 units per minute. This is typically used for cutting operations.

Tip: Always specify the feed rate (F) when using G01 to ensure controlled movement.

Circular Interpolation (G02/G03) Example:

Code: G02 X60 Y60 I10 J0

Explanation: This command moves the tool in a clockwise arc to the coordinates (X60, Y60) with the center of the arc at an offset of (I10, J0) from the start point.

Tip: Use G02 for clockwise and G03 for counterclockwise arcs. Always define the arc center using I and J parameters.

Advanced Techniques in G-Code:

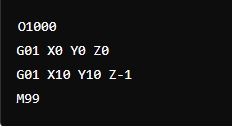

Using Subroutines and Macros:

Subroutines: Allow you to define a set of commands once and call them multiple times in your program.

Call the subroutine with M98 P1000 L3 to repeat it three times.

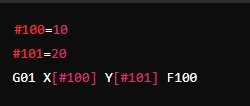

Parametric Programming:

Explanation: This program uses variables (#100 and #101) to define coordinates. This makes the program more flexible and easier to update.

5-Axis Machining Techniques:

Explanation: Advanced G-code commands enable precise control over 5-axis CNC machines, allowing for complex part geometries.

Example: G68.2 X0 Y0 Z0 A45 B30 to rotate the coordinate system for complex machining.

Toolpath Optimization Techniques:

Trochoidal Milling: Used to optimize toolpaths for efficient material removal and extended tool life.

Example: Use CAM software to generate optimized toolpaths and convert them to G-code.

Advanced G Code Commands and Techniques

For experienced users, advanced G-code commands offer greater control and efficiency. Here are some advanced techniques to enhance your machining processes.

Subroutines and Macros: Use subroutines to repeat code blocks and macros for complex sequences.

Parametric Programming: Incorporate variables and equations to create flexible, adaptive programs.

5-Axis Machining: Advanced G-code commands enable precise control over 5-axis CNC machines, allowing for complex part geometries.

Toolpath Optimization: Techniques like trochoidal milling and adaptive clearing improve material removal rates and tool life.

Common Challenges and Troubleshooting Tips

Despite its advantages, working with G-code can present challenges. Here are some common issues users face and practical tips for troubleshooting and resolving them.

Syntax Errors: Ensure correct command formats and parameters to avoid execution errors.

Machine Calibration: Regularly calibrate machines to maintain accuracy.

Tool Wear and Breakage: Monitor tool conditions and replace them as needed.

Unexpected Movements: Check for correct coordinate settings and command sequences.

Future Trends in G Code and CNC Machining

The future of G-code and CNC machining is promising, with advancements in automation and artificial intelligence. This section explores emerging trends and their implications for the industry.

- Automation:

Increasing use of robots and automated systems in machining processes.

- AI and Machine Learning:

Enhancing G-code generation and optimization through intelligent algorithms.

- IoT Integration:

Connecting machines for real-time monitoring and control.

- Sustainability:

Developing eco-friendly machining practices and materials.

The Importance of Mastering G Code

Understanding and mastering G-code is essential for anyone involved in CNC machining and 3D printing. This conclusion reinforces the importance of continuous learning and adaptation in this field.

G-code is integral to modern manufacturing, from CNC machining to 3D printing. Mastering G-code opens up new possibilities for precision and efficiency in production. Continuous improvement and adaptation to new technologies will ensure sustained success and innovation in the competitive field of manufacturing.

Summary

G-code is integral to modern manufacturing, from CNC machining to 3D printing. Mastering G-code opens up new possibilities for precision and efficiency in production. Keep exploring, learning, and applying these commands to stay ahead in the competitive field of manufacturing.

G code table

| Code | Function | Suitable Machining Process |

|---|---|---|

| G00 | Rapid positioning | Turning, milling, drilling, etc. |

| G01 | Linear interpolation | Turning, milling, drilling, etc. |

| G02 | Clockwise circular interpolation | Turning, milling, drilling, etc. |

| G03 | Counterclockwise circular interpolation | Turning, milling, drilling, etc. |

| G04 | Dwell (pause) | Turning, milling, drilling, etc. |

| G17 | Select XY plane | Milling |

| G18 | Select XZ plane | Turning |

| G19 | Select YZ plane | Turning |

| G20 | Inch units | Turning, milling, drilling, etc. |

| G21 | Metric units | Turning, milling, drilling, etc. |

| G28 | Return to reference point | Turning, milling, drilling, etc. |

| G40 | Cancel cutter radius compensation | Turning, milling, etc. |

| G41 | Cutter radius compensation left | Turning, milling, etc. |

| G42 | Cutter radius compensation right | Turning, milling, etc. |

| G43 | Tool length compensation positive | Milling |

| G44 | Tool length compensation negative | Milling |

| G49 | Cancel tool length compensation | Milling |

| G54 | Select work coordinate system 1 | Turning, milling, drilling, etc. |

| G55 | Select work coordinate system 2 | Turning, milling, drilling, etc. |

| G56 | Select work coordinate system 3 | Turning, milling, drilling, etc. |

| G57 | Select work coordinate system 4 | Turning, milling, drilling, etc. |

| G58 | Select work coordinate system 5 | Turning, milling, drilling, etc. |

| G59 | Select work coordinate system 6 | Turning, milling, drilling, etc. |

| G80 | Cancel fixed cycle | Drilling, boring, etc. |

| G81 | Drilling fixed cycle | Drilling |

| G82 | Drilling fixed cycle with dwell | Drilling |

| G83 | Peck drilling cycle | Drilling |

| G84 | Tapping cycle | Tapping |

| G85 | Boring cycle | Boring |

| G90 | Absolute programming | Turning, milling, drilling, etc. |

| G91 | Incremental programming | Turning, milling, drilling, etc. |

| G92 | Set work coordinate system | Turning, milling, drilling, etc. |

| G94 | Feed per minute | Turning, milling, drilling, etc. |

| G95 | Feed per revolution | Turning, milling, drilling, etc. |

FAQs on G-Code

What are the three basic G codes?

The three basic G-codes are:

- G00: Rapid move to a specific coordinate position.

- G01: Linear feed move.

- G02/G03: Clockwise/counterclockwise feed move.

How hard is it to learn G-code?

Learning G-code can be challenging initially, but it is regarded as one of the easier programming languages to master. With practice, one can become proficient in programming CNC machines using G-code.

Can G-code be used for both CNC machining and 3D printing?

Yes, G-code is used extensively in both CNC machining and 3D printing. In CNC machining, it controls the movement of machine tools, while in 3D printing, it directs the print head and extrusion of material.