In the world of CNC machining, understanding the intricacies of machine language is crucial for precision and efficiency. One such essential component is M Code.

M Code is a set of commands used in CNC programming to control machine functions that are not related to movements. For example, M03 activates the spindle to rotate clockwise, while M04 commands it to rotate counterclockwise. These commands are critical for the operational aspects of CNC machines, ensuring precise control over various machine functions.

Understanding the basics of M Code is just the beginning. Let’s dive deeper into its various aspects to fully grasp its importance in CNC machining.

What is M-Code?

M Code stands for “Miscellaneous Code,” an integral part of CNC (Computer Numerical Control) programming. These codes control various machine functions that do not involve the actual movement of the machine. Historically, M Code has been essential in automating complex machining processes, allowing for greater precision and efficiency.

M Code commands are often machine-specific, meaning they can vary depending on the manufacturer and model of the CNC machine. However, some common M Codes are standardized across many machines, such as M03 for spindle on clockwise, M04 for spindle on counterclockwise, and M30 for program end with reset.

The Functions of M-Code

M Code commands are crucial for controlling non-movement functions in CNC machines. These commands include starting and stopping the spindle, turning on and off the coolant, changing tools, and controlling auxiliary devices. Understanding the functions of M Code is vital for any CNC operator as it ensures the smooth operation of the machine. Incorrect usage of M Codes can lead to machine malfunctions or suboptimal machining results. Here, we will categorize and delve into the specific functions of M Codes:

Spindle Control Functions

The spindle is a vital component of CNC machines, responsible for holding and rotating the cutting tool. M Codes related to spindle control include:

- M03 (Spindle On Clockwise): Starts the spindle rotating in a clockwise direction. This is commonly used for right-hand cutting tools.

- M04 (Spindle On Counterclockwise): Starts the spindle rotating in a counterclockwise direction, typically used for left-hand cutting tools.

- M05 (Spindle Stop): Stops the spindle from rotating. This command is used to halt the spindle after a machining operation or before a tool change.

Coolant Control Functions

Coolant is essential in CNC machining to reduce heat and friction, improve tool life, and enhance the quality of the finished part. M Codes for coolant control include:

- M08 (Coolant On): Turns on the coolant system to begin cooling the cutting tool and workpiece. This helps in maintaining optimal machining conditions.

- M09 (Coolant Off): Turns off the coolant system. This is usually done at the end of a machining operation or when coolant is no longer needed.

Tool Change Functions

Tool changes are necessary in CNC operations that require multiple tools for different machining tasks. M Codes for tool change functions include:

- M06 (Tool Change): Initiates a tool change cycle. This command signals the machine to switch to a different tool specified in the program, enabling multi-tool operations without manual intervention.

Program Control Functions

These functions help in managing the execution and flow of CNC programs. They include:

- M00 (Program Stop): Temporarily stops the program. The spindle and coolant remain on. This is used for temporary halts in the program, allowing the operator to inspect the part or make adjustments.

- M01 (Optional Stop): Similar to M00, but only stops if the optional stop switch on the machine is enabled. This allows for selective pauses in the program based on operator discretion.

- M02 (Program End): Ends the program but does not reset the program counter. It is typically used at the end of a machining cycle to signal completion.

- M30 (End of Program with Reset): Ends the program and resets the program counter to the beginning. This prepares the machine for the next operation or a repeat of the current program.

Auxiliary Functions

These functions control additional machine features and operations that enhance the machining process. Examples include:

- M07 (Mist Coolant On): Turns on the mist coolant system, which sprays a fine mist of coolant onto the cutting area.

- M19 (Spindle Orientation): Orients the spindle to a specific angular position, useful for precise tool positioning and multi-axis machining.

- M98 (Subprogram Call): Calls a subprogram to execute repetitive tasks more efficiently, reducing the complexity of the main program.

- M99 (Subprogram Return): Returns from a subprogram to the main program, ensuring continuity and proper sequence of operations.

Importance of M Code Functions

Each M Code function plays a critical role in the overall CNC machining process. Proper use of these commands ensures:

- Operational Efficiency: Automating functions like tool changes and coolant control reduces manual intervention, saving time and increasing productivity.

- Precision and Quality: Accurate control of spindle speeds, tool positioning, and cooling helps achieve high-quality machining results.

- Safety and Maintenance: Commands like spindle stop and program stop allow for safe operation and maintenance checks, preventing accidents and equipment damage.

By understanding and effectively utilizing M Code functions, CNC operators and programmers can optimize machining processes, improve product quality, and enhance operational efficiency.

Types of M-Code

M Codes can be classified into two broad categories: mandatory and optional. Mandatory M Codes are essential for the operation of the CNC machine and must be executed for the program to run correctly. Optional M Codes, on the other hand, can be executed based on the requirement of the specific machining process.

Mandatory M Codes

These include commands like M03 (Spindle On – Clockwise), M05 (Spindle Stop), and M30 (End of Program). These codes are essential for the basic functioning of the CNC machine. Mandatory M Codes ensure that the essential functions of the machine are carried out without fail, thereby maintaining the operational integrity of the CNC process.

Optional M Codes

These include commands like M01 (Optional Stop), which pauses the program if an optional stop is enabled on the machine. Optional M Codes provide additional flexibility in programming and can be used to enhance the efficiency of the machining process. For instance, an optional stop allows the operator to inspect the part, change settings, or perform maintenance without stopping the entire program.

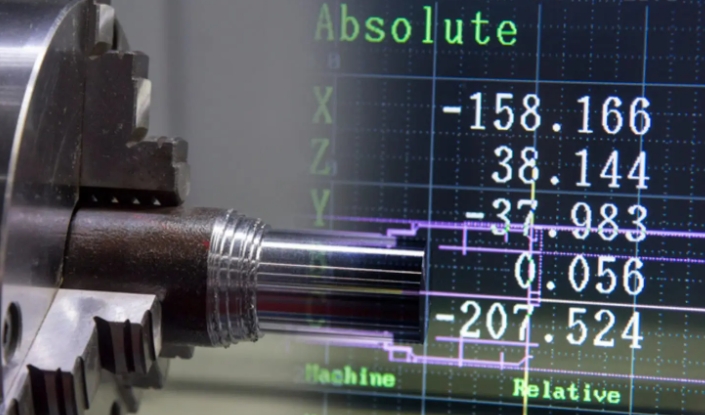

M Code in CNC Machines

The implementation of M Code in CNC machines is crucial for their operation. Each M Code corresponds to a specific function that the machine performs. For example, in a CNC lathe, M03 would turn the spindle on clockwise, which is essential for cutting operations.

In practical applications, M Codes are used extensively to automate processes that would otherwise require manual intervention. This automation increases productivity, reduces errors, and ensures consistent machining quality. For instance, in a CNC milling machine, M07 might turn on the mist coolant, ensuring that the cutting tool and workpiece are adequately cooled during machining.

Case Study: Automotive Industry

In the automotive industry, CNC machines are used to manufacture complex parts with high precision. M Codes play a critical role in this process. For instance, M06 (Tool Change) is frequently used to switch between different cutting tools, ensuring that each part is machined to exact specifications. The ability to change tools automatically without manual intervention significantly reduces machining time and increases productivity.

Automotive parts such as engine components, transmission parts, and suspension parts require high precision and consistency. By using M Codes to control various aspects of the machining process, manufacturers can ensure that each part meets the stringent quality standards required in the automotive industry.

Differences Between M Code and G Code

While M Code and G Code are both essential for CNC programming, they serve different purposes. G Code primarily deals with the movement of the machine, such as positioning, cutting paths, and feed rates. In contrast, M Code controls the machine’s auxiliary functions.

G Code Examples

- G00: Rapid positioning, used to move the machine quickly to a specified location without cutting.

- G01: Linear interpolation, used for straight-line cutting at a specified feed rate.

- G02: Circular interpolation clockwise, used for cutting arcs in a clockwise direction.

M Code Examples

- M03: Spindle on clockwise, used to start the spindle rotating in a clockwise direction.

- M08: Coolant on, used to turn on the coolant system.

- M30: End of program with reset, used to end the current program and reset the machine to its initial state.

Understanding the interplay between M Code and G Code is crucial for CNC operators to program machines effectively. Both types of codes work together to achieve the desired machining outcomes. For example, a typical CNC program might start with G00 to move the machine to the starting position, followed by M03 to start the spindle, and then use G01 to begin the cutting operation.

Commonly Used M Codes

Here are some of the most commonly used M Codes in CNC programming:

- M00 (Program Stop)

This command stops the machine but does not turn off the spindle or coolant. It is used for temporary halts in the program. For example, M00 might be used to stop the machine so that the operator can inspect the workpiece or make adjustments before continuing the program.

- M01 (Optional Stop)

Similar to M00, but it only stops if the optional stop switch on the machine is enabled. This allows for greater flexibility in programming, as the operator can choose whether or not to stop the machine at specific points in the program.

- M02 (Program End)

Ends the program but does not reset the program counter. This is typically used at the end of a machining cycle to signal that the program has completed its operations.

- M03 (Spindle On Clockwise)

Starts the spindle in a clockwise direction. This is a common command used in various machining operations, particularly in turning and milling.

- M04 (Spindle On Counterclockwise)

Starts the spindle in a counterclockwise direction. This command is used less frequently but is essential for certain operations where the cutting tool needs to rotate in the opposite direction.

- M05 (Spindle Stop)

Stops the spindle from rotating. This command is used to halt the spindle after a machining operation has been completed or when a tool change is required.

- M06 (Tool Change)

Initiates a tool change cycle. This command is essential in multi-tool machining operations, allowing the machine to switch between different tools automatically.

- M08 (Coolant On)

Turns the coolant on. Coolant is crucial for cooling the cutting tool and workpiece, reducing heat and friction, and improving the quality of the machined part.

- M09 (Coolant Off)

Turns the coolant off. This command is used at the end of a machining operation or when coolant is no longer needed.

- M30 (End of Program with Reset)

Ends the program and resets the program counter to the beginning. This command is typically used at the end of a machining cycle to prepare the machine for the next operation.

Advanced M Code Functions

Advanced M Code functions are used for more complex machining operations and provide greater control over the CNC machine. These include custom M Codes defined by the user or specific to certain types of machines.

- M98 (Subprogram Call)

Used to call a subprogram, which allows the main program to execute repetitive tasks more efficiently. Subprograms are useful for complex machining operations that require repeating the same sequence of commands multiple times.

- M99 (Subprogram Return)

Used to return from a subprogram to the main program. This command ensures that the machine resumes the main program after completing the subprogram tasks.

- M19 (Spindle Orientation)

Used to orient the spindle to a specific angular position. This is particularly useful in operations where precise tool positioning is critical, such as in multi-axis machining or when aligning the tool with a specific feature on the workpiece.

Understanding M Code Syntax

M Code syntax is relatively straightforward, but it is essential to understand its structure to avoid errors. Each M Code command typically consists of the letter ‘M’ followed by a two-digit number (e.g., M03).

Example Syntax

- M03 S1500: This command turns the spindle on clockwise at 1500 RPM.

- M06 T02: This command initiates a tool change to tool number 2.

Proper syntax ensures that the machine interprets the commands correctly, leading to precise machining operations. It is also important to follow the correct sequence of commands to avoid conflicts and ensure smooth operation.

Common Errors and How to Avoid Them

Incorrect M Code: Using an incorrect M Code can lead to unexpected machine behavior. Always refer to the machine’s manual or documentation to ensure the correct M Code is used.

Syntax Errors: Missing or misplaced characters in the M Code can cause the machine to misinterpret the command. Double-check the syntax before running the program.

Sequence Errors: The order of M Codes can affect the operation of the machine. Ensure that commands are in the correct sequence to avoid conflicts and ensure smooth operation.

M Code in Modern CNC Software

Modern CNC software has advanced significantly, incorporating M Code into more user-friendly interfaces. Programs like Mastercam, Fusion 360, and others allow users to input M Code commands easily, integrating them with G Code to create comprehensive machining programs.

These software tools often include simulation features that allow users to visualize the machining process, ensuring that the M Codes and G Codes work together seamlessly. Simulation helps in identifying potential errors and optimizing the program before it is run on the actual machine.

Integration with CAM Software

Computer-Aided Manufacturing (CAM) software integrates M Code and G Code to generate CNC programs. CAM software automates the creation of toolpaths and includes M Codes for controlling various machine functions. This integration enhances efficiency and accuracy in CNC programming.

Benefits of Modern CNC Software

- User-Friendly Interface: Modern CNC software provides an intuitive interface for creating and editing CNC programs. This makes it easier for operators to input M Codes and G Codes.

- Simulation and Verification: Simulation features help in verifying the program before running it on the machine. This reduces the risk of errors and ensures that the program will run smoothly.

- Optimization: Modern software includes tools for optimizing toolpaths and machining parameters. This helps in improving efficiency and reducing machining time.

Choosing the Best M Code Simulator

Selecting the right M Code simulator is crucial for CNC programmers and operators. A good simulator allows you to test and validate your CNC programs before running them on the actual machine, reducing the risk of errors and enhancing efficiency.

Features to Look For

- Realistic Simulation: The simulator should provide a realistic representation of the CNC machine and its operations.

- Compatibility: Ensure that the simulator is compatible with the specific CNC machine and software you are using.

- Ease of Use: The simulator should have an intuitive interface that makes it easy to input and edit M Codes.

- Error Detection: A good simulator will detect syntax errors and other issues in the M Code, helping you to correct them before running the program.

- Visualization: Look for simulators that offer visual representation of the machining process, allowing you to see how the machine will operate with the given M Codes.

Top M Code Simulators

CIMCO Edit: Known for its powerful simulation capabilities and user-friendly interface. It supports a wide range of CNC machines and provides detailed error checking.

NCPlot: A versatile tool that combines editing and simulation, making it ideal for CNC programmers. It offers advanced plotting features and supports both G Code and M Code.

G-Wizard Editor: This simulator provides a comprehensive suite of tools for editing and simulating CNC programs. It includes built-in help and tips for optimizing your M Code.

VERICUT: A high-end simulation software used by many industries for its accuracy and advanced features. It provides detailed simulation and error detection, ensuring that your CNC programs run smoothly.

Who Needs to Learn M Code?

Understanding M Code is essential for various professionals involved in CNC machining. Here are some key groups who should learn M Code:

- CNC Operators

CNC operators are responsible for running the machines and ensuring that they operate correctly. Knowledge of M Code allows operators to troubleshoot issues, make necessary adjustments, and ensure that the machine functions as intended.

- CNC Programmers

CNC programmers create the programs that control the CNC machines. A deep understanding of M Code is crucial for writing effective programs that maximize efficiency and precision. Programmers need to know how to use M Code to control various machine functions and optimize the machining process.

- Maintenance Technicians

Maintenance technicians need to understand M Code to diagnose and fix issues with CNC machines. Knowledge of M Code helps technicians identify the root cause of problems and perform necessary repairs or adjustments.

- Engineers

Engineers involved in the design and manufacturing process benefit from understanding M Code. This knowledge allows them to design parts and processes that are optimized for CNC machining, improving overall productivity and quality.

- Educators and Students

Educators teaching CNC machining and related subjects need to have a thorough understanding of M Code to effectively train their students. Students learning CNC programming and machining should also master M Code to prepare for careers in the industry.

The Future of M Code

The future of M Code is likely to see further integration with advanced technologies such as artificial intelligence (AI) and machine learning (ML). These technologies can optimize CNC programming by predicting and preventing potential errors, enhancing precision, and improving overall efficiency.

AI and Machine Learning

AI and ML can analyze large amounts of data from CNC operations to identify patterns and optimize machining processes. For example, AI algorithms can predict tool wear and adjust the machining parameters to extend tool life and improve surface quality.

Development of New M Codes

As new materials and machining techniques are developed, new M Codes may be created to support these innovations. The continuous evolution of CNC technology ensures that M Code will remain a vital component of machining processes.

Integration with IoT

The Internet of Things (IoT) is transforming manufacturing by connecting machines and devices to a network. This allows for real-time monitoring and control of CNC machines, enhancing efficiency and reducing downtime. M Codes can be integrated with IoT systems to automate and optimize various aspects of the machining process.

Conclusion

Mastering M Code is essential for CNC operators and engineers to ensure precision and efficiency in machining operations. By understanding and effectively utilizing M Code, one can achieve greater control and accuracy in CNC processes, ultimately leading to improved productivity and product quality.

M code table

| M Code | Function | Suitable Machining Process |

|---|---|---|

| M00 | Program stop | All machining processes |

| M01 | Optional stop | All machining processes |

| M02 | Program end | All machining processes |

| M03 | Spindle on clockwise | Turning, Milling |

| M04 | Spindle on counterclockwise | Turning, Milling |

| M05 | Spindle stop | Turning, Milling |

| M06 | Tool change | Milling, Drilling |

| M07 | Mist coolant on | Milling, Turning |

| M08 | Coolant on | Milling, Turning |

| M09 | Coolant off | Milling, Turning |

| M10 | Clamp fixture | Milling, Turning |

| M11 | Unclamp fixture | Milling, Turning |

| M12 | Spindle forward retract | Turning |

| M13 | Spindle forward feed | Turning |

| M14 | Spindle reverse feed | Turning |

| M15 | Spindle reverse retract | Turning |

| M19 | Spindle orientation | Milling, Turning |

| M30 | Program end and reset | All machining processes |

| M41 | Low gear range | Turning |

| M42 | Medium gear range | Turning |

| M43 | High gear range | Turning |

| M48 | Cancel feed rate override | All machining processes |

| M49 | Cancel spindle speed override | All machining processes |

| M60 | Tool change position | Milling, Drilling |

| M98 | Subprogram call | All machining processes |

| M99 | Return from subprogram | All machining processes |

| M101 | First auxiliary clamp on | Milling, Turning |

| M102 | First auxiliary clamp off | Milling, Turning |

| M103 | Second auxiliary clamp on | Milling, Turning |

| M104 | Second auxiliary clamp off | Milling, Turning |

| M110 | Automatic tool measurement | Milling, Drilling |

| M111 | Tool life monitoring | Milling, Drilling |

| M112 | Tool breakage detection | Milling, Drilling |

| M113 | Tool preheat | Milling, Drilling |

| M120 | Laser on | Laser machining |

| M121 | Laser off | Laser machining |

| M130 | Printer head on | 3D printing |

| M131 | Printer head off | 3D printing |

FAQs

What is M language code?

M language, also known as Power Query M formula language, is a data transformation language used in Microsoft Power Query. It is designed to be both user-friendly and powerful, enabling users to manipulate and transform data from various sources. M language is a functional, case-sensitive language that is used in Power BI, Power Query in Excel, and other Microsoft data products. Its primary purpose is to perform data extraction, transformation, and loading (ETL) operations. The language allows users to combine, filter, clean, and reshape data in a flexible and reusable manner.

What is the M-Code in Excel?

In Excel, M-Code refers to the scripting language used by Power Query, which is a tool for data transformation and manipulation. Despite sharing the term “M-Code,” this M-Code has no relation to CNC programming. The M-Code in Excel is part of the Power Query M formula language, which allows users to extract, transform, and load (ETL) data from various sources. This code enables advanced data processing tasks such as filtering, sorting, and combining data tables. Users can view and edit M-Code in the Power Query Editor to customize their data transformations and automate complex data preparation workflows within Excel.