Many manufacturers struggle with efficiency and precision in their production processes. Machining centers, equipped with advanced CNC technology, offer a solution by automating complex machining tasks, thus boosting productivity and accuracy.

Machining center is a CNC machine capable of milling, drilling, boring, tapping, and more. It can automatically change tools without re-positioning the workpiece, greatly enhancing productivity and precision.

After understanding the basic definition, let’s delve into the different types, main components, and practical applications of machining centers. Let us better understand and utilize this advanced equipment.

What is a Machining Center?

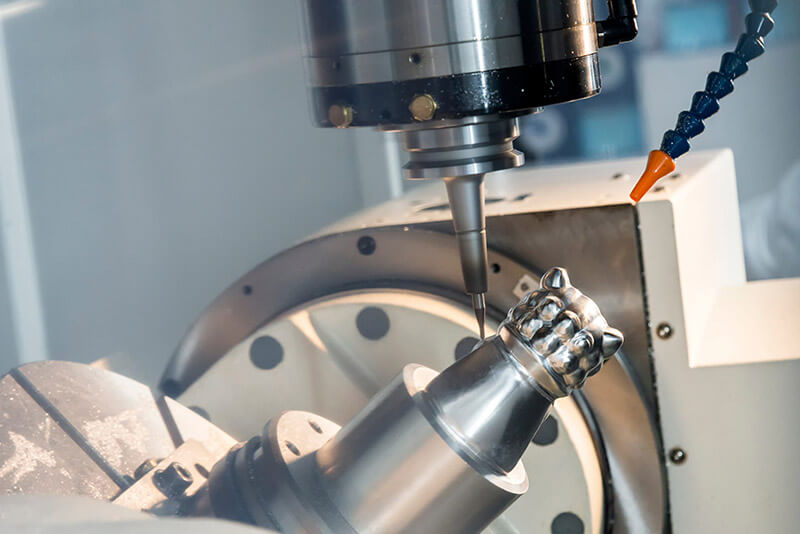

A machining center is a CNC machine tool with a tool magazine, an automatic tool changer, and the ability to perform multiple machining processes after clamping the workpiece once. It is a highly mechatronic product. The workpiece is clamped, and the CNC system controls the machine tool to perform different processes, automatically selects and changes tools, automatically sets tool length, automatically changes spindle speed and feed rate, and can perform continuous drilling, boring, milling, reaming, tapping, and other processes. This greatly reduces workpiece clamping time, measurement and machine tool adjustment time, and the time for auxiliary processes such as drilling, boring, milling, reaming, and tapping for workpieces with complex shapes, high precision requirements, and frequent tool changes, achieving good economic results.

The History of Machining Centers

- 1950s: The birth of CNC machines laid the foundation for machining centers.

- 1960s: Kearney & Trecker invented the first machining center in the United States.

- 1970s: Automatic tool change systems were gradually introduced, improving efficiency.

- 1980s: Advancements in computer technology made CNC systems smarter and more efficient.

- 1990s: Multi-axis machining centers became popular, enabling more complex part machining.

- 21st Century: Continuous advancements have led to five-axis and composite machining centers.

Components of a Machining Center

A machining center consists of several key components, each with specific functions and maintenance requirements:

Machine Bed: Includes the base, column, and table, providing mechanical support for machining. Regularly check for wear and tear, lubricate moving parts, and make necessary adjustments.

CNC System: Controls the machine’s operations and movements, usually comprising a computer and software. Regularly update software, inspect electrical connections, and troubleshoot system issues to ensure stability.

Tool Magazine: Stores various tools for automatic tool changes. Regularly inspect for tool wear, replace damaged tools, and clean the magazine.

Tool Changer: Automatically switches tools to improve efficiency. Regularly check mechanical parts, ensure smooth operation, and replace worn components.

Spindle System: Includes the spindle motor and spindle body, providing cutting power. Regularly check lubrication, monitor temperature and vibration, and ensure proper operation.

Servo Motors and Drives: Control the movements of each axis for precise machining. Regularly inspect motors and drives, ensuring they function correctly.

Cooling System: Includes a coolant pump and tank, controlling temperature during cutting. Regularly replace coolant, clean the tank, and check the pump’s operation.

Chip Conveyor: Removes chips generated during machining, keeping the work area clean. Regularly clean chips and replace damaged parts.

Control Panel: Operators use it to input machining programs and control parameters. Regularly inspect buttons and displays to ensure proper function.

Machining Center Basic Process

Machining centers can do many things, including:

Milling: This is when you use a spinning cutter to take material off the surface of the part to create shapes and finishes.

Drilling: This is when you use a drill bit to make a round hole in the part. This is used in a lot of different manufacturing.

Boring: This is when you make a hole bigger and better. It makes the hole more accurate and the surface better.

Tapping: This is when you use a tap to cut threads inside a hole so you can screw something into it.

Reaming: This is when you use a reamer to finish a hole to make it more accurate and the surface better.

Countersinking: This is when you make a cone shape at the end of a hole so a screw head or something else can sit flush with the surface.

Edge Milling: This is when you take the burrs off the edge of the part and make it smooth and clean.

Engraving: This is when you use a tool to write or make a pattern on the surface of the part. It’s used a lot in making molds and signs.

Types and Prices of Machining Centers

Vertical Machining Centers (VMC)

The spindle is up and down, and it’s good for small to medium parts. They cost between $50,000 and $200,000 and are good for general machining.

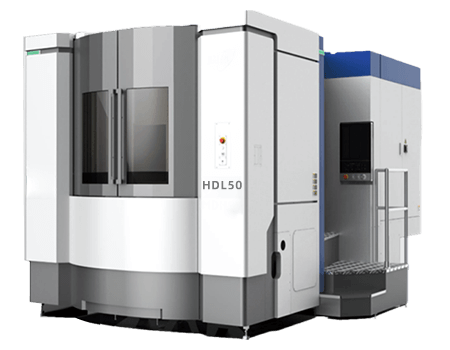

Horizontal Machining Centers (HMC)

The spindle is side to side, and it’s good for big and complicated parts. They cost between $100,000 and $500,000 and are good for machining big parts from multiple sides.

Gantry Machining Centers

They have big tables and are really stiff. They’re good for big and heavy parts. They cost between $500,000 and $2,000,000 and are used in aerospace and shipbuilding.

Composite Machining Centers

They can turn and mill, so you can do a lot of things in one setup. They cost between $200,000 and $800,000 depending on how you set them up.

Advantages and Disadvantages of Machining Centers

Advantages:

High Precision: Machining centers can achieve high levels of accuracy, making them suitable for complex and detailed parts.

Increased Productivity: Automation and tool changing capabilities reduce downtime and increase production rates.

Versatility: Capable of performing multiple operations such as milling, drilling, and tapping in a single setup.

Consistency: Computer-controlled processes ensure consistent and repeatable results.

Reduced Labor Costs: Automation reduces the need for manual intervention, lowering labor costs.

Disadvantages:

High Initial Cost: The purchase and installation of machining centers require significant investment.

Complex Maintenance: Requires regular maintenance and skilled technicians to ensure proper operation.

Training Requirements: Operators need extensive training to handle the advanced CNC systems.

Space Requirements: Machining centers, especially larger models, require substantial floor space.

Spindle Types in Machining Centers

Machining centers have a few different types of spindles:

- X-axis: This is left and right.

- Y-axis: This is front and back.

- Z-axis: This is up and down.

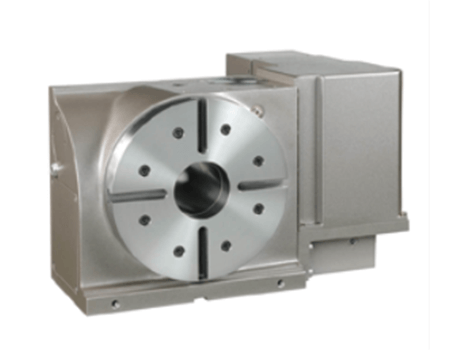

- B-axis: This rotates the table or the tool to give you more options.

- C-axis: This rotates the spindle to let you do more complicated machining on the surface.

Axis Configurations and Costs

3-axis Machining Centers

X, Y, and Z axes. These are good for most jobs. They cost between $50,000 and $150,000.

4-axis Machining Centers

This adds a rotating axis so you can do more complicated machining. They cost between $150,000 and $300,000.

5-axis Machining Centers

These have five different ways they can move so you can do full 3D machining. They usually start at $300,000 and go up from there.

Major Applications of Machining Centers

Machining centers are used in a lot of different industries:

- Aerospace: They make parts for airplanes and engines that need to be really accurate and reliable.

- Automotive: They make parts like engine blocks and transmissions.

- Mold Making: They make all kinds of molds, including plastic and die-cast molds.

- Electronics: They make really accurate parts like phone cases and laptop shells.

Factors Affecting Machining Center Prices

The price of machining centers can be affected by a few things:

Brand: More well-known brands cost more, but they usually have better quality and service.

Model and Configuration: The higher-end, high-performance models cost more, especially if they have more axes and composite functions.

Precision and Speed: The more accurate and faster the machining center, the more it costs because of the technology and materials.

Automation Level: The more automation, like automatic tool changers and loaders, the more it costs.

After-sales Service: The more service and training you get after you buy it, the more it costs.

CNC vs. Machining Centers

While both CNC machines and machining centers are used for precision manufacturing, machining centers offer more advanced capabilities. A machining center is essentially an upgraded CNC machine that provides automatic tool changing and higher precision. It combines multiple machining processes like milling, drilling, and tapping in one machine, enhancing productivity and versatility.

Differences Between Machining Centers and Turning Centers

A machining center does rotating spindle work, while a turning center does turning work. The machining center is used for multi-sided machining of complex parts, while the turning center is used for machining shaft parts.

How to Choose a Machining Center

Here are some factors to consider when choosing a machining center:

Machining requirements: Choose the type of machining center based on the size and complexity of the workpieces you’ll be making.

Budget: Determine your budget and find the best machine you can get for the money.

Brand reputation: Buy from a reputable brand with good service and support.

After-sales service: Make sure the company you buy from provides training, maintenance, and troubleshooting support.

Machine performance: Look at the machine’s spindle speed, tool magazine capacity, and maximum machining envelope to make sure they meet your needs.

Programming and Controlling a Machining Center

Machining centers use CNC programming languages (like G-code) to program them. You input the machining program into the CNC system. The CNC system controls the tool paths and machining parameters to make the machine do what you want it to do.

Conclusion

That’s a quick overview of machining centers. Minnuo makes great machining centers. If you need a machining center, check out the Minnuo website.