Turning is a fundamental machining process widely used in various industries. Understanding its principles, history, and applications can significantly enhance manufacturing efficiency and product quality.

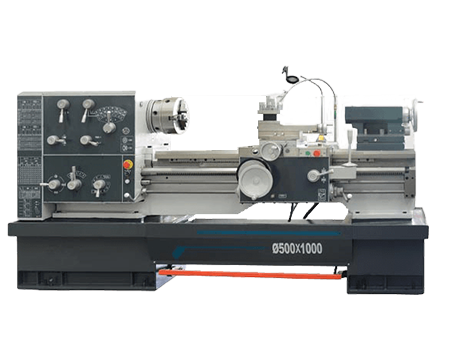

Turning is a high-precision metal cutting process that involves rotating the workpiece and moving the tool to machine external rounds, bores, threads, etc. It is suitable for a wide range of metals. Modern lathes often use CNC technology to improve the degree of automation and processing efficiency. It is one of the most basic and essential machining operations, applicable to both external and internal surfaces of parts.

By examining its history, principles, types, and tools, we can appreciate the comprehensive nature of turning and its significance in modern industry.

What is Turning?

Understanding the basic concept of turning is essential before delving into its history and applications. Let’s explore what turning involves and why it is so fundamental to machining processes.

Turning involves rotating a workpiece on a lathe while a cutting tool removes material to shape the part. This process can be performed on both external and internal surfaces. The lathe machine plays a crucial role here, holding and rotating the workpiece while various cutting tools are applied to achieve the desired shape. Turning operations are typically performed to create cylindrical parts, but with advanced techniques, more complex geometries can be achieved. Additionally, turning is used to refine the surface finish and achieve precise dimensional accuracy.

The History of Turning

The history of turning is rich and spans thousands of years. Key advancements have significantly shaped the process we know today. Here are some pivotal moments in the development of turning technology.

- Ancient Egypt (1300 BC): The earliest known use of a lathe, operated manually with a two-person system. One person would turn the workpiece while the other used a cutting tool to shape it.

- 19th Century: Industrial Revolution brought steam-powered lathes, significantly increasing production capacity. The use of steam power enabled the machining of larger and more complex parts with greater efficiency.

- 1950s: Advent of Computer Numerical Control (CNC) technology, revolutionizing precision and automation in turning. CNC lathes automated many aspects of the turning process, allowing for more complex geometries and higher precision.

- 21st Century: Integration of AI and IoT into CNC machines, enhancing real-time monitoring and process optimization. These advancements have led to smarter manufacturing processes, improving efficiency and reducing downtime.

How Turning Works

Understanding how turning works is crucial to mastering the technique. Let’s explore the fundamental principles and components involved in the turning process.

The workpiece is clamped and rotated at high speeds, while the cutting tool moves linearly, removing material to achieve the desired dimensions and surface finish. The cutting tool’s movement is parallel to the workpiece’s axis, allowing for precise control over the final shape and dimensions of the part. This basic principle remains the same whether the process is manual or automated.

The key components of a turning operation include:

- Lathe Bed: The base of the lathe, providing stability and support for all other components.

- Headstock: Contains the spindle, which holds and rotates the workpiece.

- Tailstock: Supports the other end of the workpiece, especially important for longer pieces.

- Carriage: Moves the cutting tool along the workpiece.

- Cutting Tool: The tool that removes material from the workpiece.

Critical parameters in the turning process include rotational speed (RPM), feed rate, and depth of cut. These must be carefully controlled to achieve the desired results.

Types of Turning

Turning encompasses a variety of techniques, each suited for specific shapes and features. Understanding these different types helps in selecting the right method for the desired application.

Straight Turning

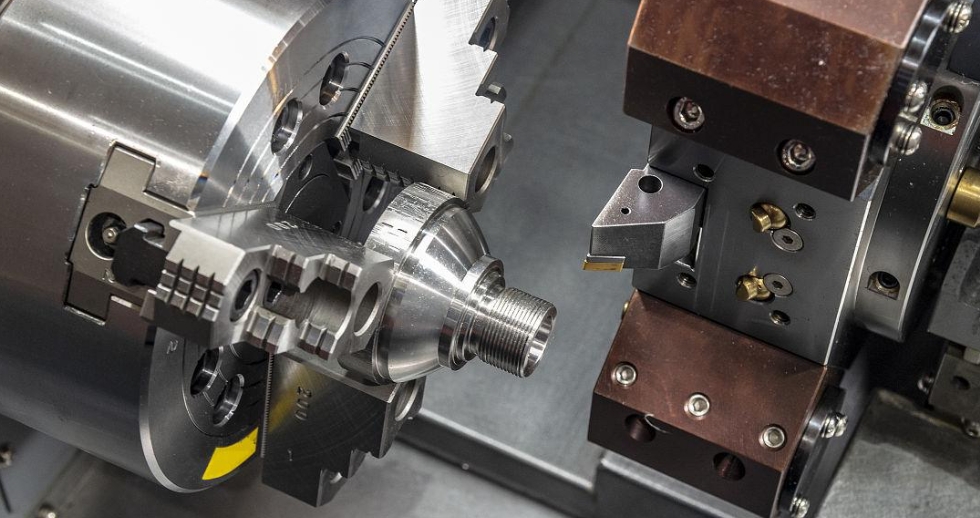

Straight turning produces a cylindrical shape by removing material along the workpiece’s length. This is the most basic form of turning and is often used as the first step in machining operations. It involves a simple linear motion of the cutting tool along the axis of the rotating workpiece, creating a uniform diameter throughout the length of the part.

Taper Turning

Taper turning creates a conical shape by gradually changing the diameter of the workpiece. This type of turning is commonly used to produce parts that require a gradual change in diameter, such as tapered shafts and connectors. Taper turning can be achieved by adjusting the angle of the cutting tool or by offsetting the tailstock.

Profiling

Profiling involves creating complex shapes by moving the cutting tool in various paths. Profiling allows for the creation of intricate shapes and designs, making it essential for custom parts and prototypes. This technique is often used in decorative turning, where aesthetic qualities are as important as functional ones.

External Grooving

External grooving cuts grooves or channels into the workpiece surface. Grooving is often used to create features such as O-ring seats and retaining rings. This process requires precise control to ensure that the grooves are of the correct depth and width.

Internal Turning

Internal turning, also known as boring, involves enlarging or finishing the inside diameter of a hole in the workpiece. This type of turning is used to create precise internal diameters and is essential for parts like bushings and bearings.

Facing

Facing is a turning operation where the cutting tool moves perpendicular to the axis of rotation, producing a flat surface at the end of the workpiece. This process is often used to prepare the end of a part for subsequent operations or to achieve a smooth, flat surface.

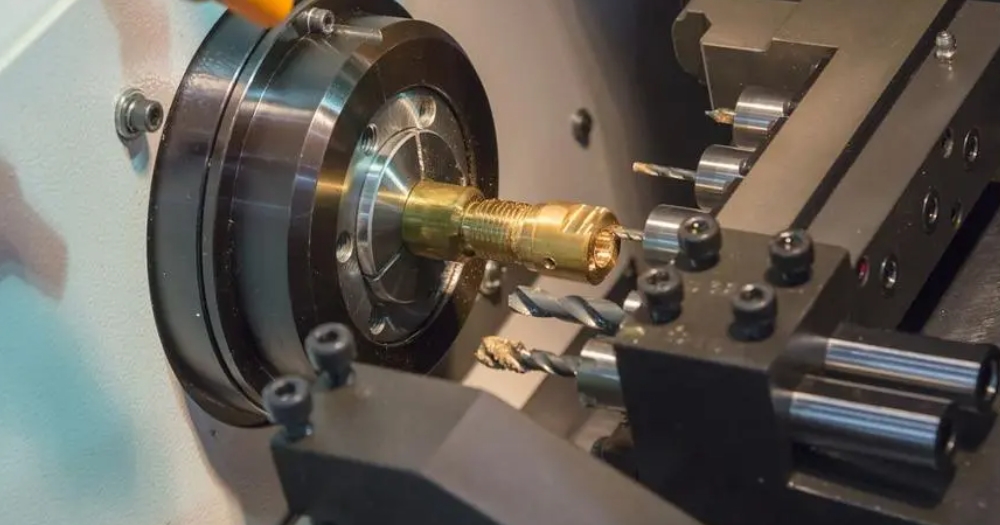

Threading

Threading is the process of creating helical grooves on the exterior or interior of a cylindrical part. This is typically done to create screw threads, which are essential for fasteners and other mechanical components. Threading requires precise synchronization of the cutting tool movement with the rotation of the workpiece.

Drilling

Drilling on a lathe involves creating holes in the workpiece using a drill bit. While drilling is often associated with drill presses, it can also be performed on a lathe for greater precision and alignment with other turning operations.

Knurling

Knurling is a process of creating a patterned surface on the workpiece to improve grip. This is commonly seen on tool handles and other parts where a textured surface is beneficial.

Advantages and Disadvantages of Turning

Like any machining process, turning has its advantages and disadvantages. Understanding these can help in making informed decisions about its applications and limitations.

Advantages:

- High Precision: Turning allows for precise control over dimensions and surface finish, making it ideal for producing high-precision components.

- Smooth Surface Finish: The nature of the turning process results in smooth surfaces, which are often required for critical parts in various industries.

- Versatility: Turning can be used to produce a wide range of shapes and sizes, from simple cylindrical parts to complex geometries.

- Scalability: Turning is suitable for both small-scale and mass production, making it flexible for various manufacturing needs.

- Efficiency: Modern turning operations, especially with CNC, can be highly efficient with minimal setup times and rapid production rates.

Disadvantages:

- Limited to Cylindrical Shapes: Turning is primarily used for cylindrical parts, and producing non-cylindrical shapes can be challenging.

- Potential for Tool Wear Over Time: The cutting tools used in turning are subject to wear, which can affect the quality and precision of the machined parts. Regular maintenance and tool replacement are necessary to maintain optimal performance.

- Requires Skilled Operators for Manual Turning: While automated CNC turning has reduced the need for skilled operators, manual turning still requires a high level of expertise to achieve precise results.

- Material Waste: Although efficient, turning can produce significant material waste, especially in high-volume production.

Tools Used in Turning

The tools used in turning are critical to the success and efficiency of the process. Let’s explore the main types of tools and their specific functions in turning operations.

Cutting Inserts: Replaceable tips that handle the actual cutting. Cutting inserts are available in various shapes, sizes, and materials, including carbide, ceramic, and diamond, to suit different machining needs. These inserts are designed to be easily replaced when worn, ensuring continuous operation.

Tool Holders: Secure the cutting inserts in place. Tool holders must be rigid and precisely aligned to ensure accurate and efficient cutting. They come in various designs to accommodate different types of inserts and cutting conditions.

Boring Bars: Extend into the workpiece for internal cutting. Boring bars are used to enlarge or finish internal diameters and can be designed for various hole depths and diameters. They need to be rigid to prevent deflection and ensure precise boring operations.

Cutting Fluids: Lubricate and cool the cutting process to extend tool life and improve finish. Cutting fluids also help to remove chips from the cutting area, reducing the risk of damage to the workpiece and tools. They can be applied in various forms, including liquids, aerosols, and pastes.

Drill Bits: Used for drilling operations on the lathe, these bits are essential for creating holes and are often used in conjunction with other turning processes.

Knurling Tools: Designed to create textured patterns on the workpiece surface, improving grip and aesthetics. These tools have hardened wheels that emboss the pattern onto the rotating workpiece.

Parting Tools: Used to cut off a part from the rest of the stock. These tools must be sharp and rigid to ensure a clean, precise cut.

Materials Suitable for Turning

The choice of materials is crucial in turning operations. Different materials present unique challenges and opportunities in the machining process.

Metals:

- Steel: Known for its strength and durability, steel is widely used in turning operations. It requires robust cutting tools and appropriate cutting speeds to achieve good surface finishes and dimensional accuracy.

- Aluminum: Valued for its light weight and ease of machining, aluminum is used in applications where weight reduction is critical. It also has excellent thermal conductivity and corrosion resistance.

- Brass: With its excellent machinability and smooth finish, brass is often used for precision components. It is also resistant to corrosion and has good thermal and electrical conductivity.

- Copper: Known for its electrical and thermal conductivity, copper is used in applications requiring these properties. It can be challenging to machine due to its tendency to work-harden.

Plastics:

- ABS: A versatile plastic with good impact resistance and machinability. ABS is commonly used for prototypes and plastic parts.

- PVC: Known for its chemical resistance, PVC is used in applications requiring durability in harsh environments. It is relatively easy to machine but requires care to avoid melting.

- Nylon: Offers high strength and toughness, making it suitable for mechanical parts and components that require wear resistance.

Composites:

- Fiber-Reinforced Plastics: These materials combine high strength-to-weight ratios with resistance to corrosion and wear. They can be challenging to machine due to their abrasive nature and tendency to delaminate.

- Carbon Fiber Composites: Used in high-performance applications, these composites offer exceptional strength and stiffness but require specialized tooling and techniques to machine effectively.

Workpieces Suitable for Turning

Turning can be used to produce a wide range of workpieces. Here are some common examples and their specific applications.

Shafts:

Used in various mechanical systems to transmit power and motion. Shafts are typically turned to achieve precise dimensions and surface finishes required for efficient operation. They are used in applications such as motors, pumps, and drive systems.

Pulleys:

Used in belt and pulley systems to transmit motion and torque. Turning ensures that pulleys have the correct diameter, groove profile, and surface finish for reliable performance. Pulleys are commonly found in engines, machinery, and conveyor systems.

Bushings:

Serve as bearings or spacers in mechanical assemblies. Bushings are often turned to achieve the precise dimensions and tolerances needed for smooth and efficient operation. They are used in applications such as automotive suspensions, industrial machinery, and electrical housings.

Complex Automotive and Aerospace Components:

High-precision parts such as engine components, turbine blades, and structural elements are often produced using turning techniques. These parts require tight tolerances and high-quality finishes to ensure optimal performance and safety. Turning is essential for manufacturing critical components in industries where reliability and precision are paramount.

Medical Devices:

Turning is used to produce various medical devices and implants, such as surgical instruments, orthopedic implants, and dental components. These parts require high precision, biocompatibility, and excellent surface finishes to ensure safety and efficacy in medical applications.

Custom Prototypes:

Turning is often used in the production of custom prototypes and low-volume parts. The flexibility and precision of turning make it ideal for developing and testing new designs before committing to mass production.

Tips for Effective Turning

Mastering the art of turning involves understanding and applying several key tips and techniques. These can significantly enhance the quality and efficiency of turning operations.

- Selecting the Right Cutting Tool: Choose tools based on the material and desired finish. Different materials require different cutting tool geometries and materials to achieve the best results. For example, using a diamond-tipped tool for hard materials like ceramics can significantly improve tool life and surface finish.

- Optimizing Cutting Speeds and Feeds: Balance speed and feed rates to minimize tool wear and maximize efficiency. Too high a cutting speed can cause excessive tool wear, while too low a speed can result in poor surface finish and longer machining times. Adjusting these parameters based on material properties and tool capabilities is essential.

- Maintaining Proper Tool Alignment: Ensure tools are aligned correctly to prevent inaccuracies and tool damage. Misalignment can cause excessive tool wear, poor surface finish, and dimensional inaccuracies. Regularly checking and adjusting tool alignment can prevent these issues.

- Using Appropriate Cutting Fluids: Proper use of cutting fluids can significantly improve tool life and surface finish. Cutting fluids help to cool the cutting area, reduce friction, and remove chips. Selecting the right type of fluid and application method for the specific material and operation is crucial.

- Regular Tool Maintenance: Regularly inspect and maintain tools to ensure they are in good condition. Sharp, well-maintained tools produce better finishes and extend tool life. Implementing a tool maintenance schedule can help prevent unexpected tool failures and ensure consistent machining quality.

- Monitoring Machine Conditions: Regularly monitor the condition of the lathe and other machinery to ensure they are operating correctly. Proper maintenance of the lathe, including lubrication and alignment checks, can prevent mechanical issues that could affect the turning process.

- Using Proper Workholding Techniques: Securely clamping the workpiece is essential for precision and safety. Using appropriate workholding techniques, such as chucks, collets, or fixtures, ensures that the workpiece remains stable during machining.

- Implementing Quality Control Measures: Regularly checking the dimensions and surface finish of machined parts can help identify and correct issues early. Implementing quality control measures, such as in-process inspections and final checks, ensures that parts meet specifications and reduces the risk of defects.

The Economic Benefits of Turning

Turning offers significant economic benefits. Let’s explore how turning can be a cost-effective and efficient solution for various manufacturing needs.

Cost-Effective Manufacturing: Minimal material waste and high production rates make turning a cost-effective machining process. By optimizing cutting parameters and tool usage, manufacturers can reduce costs and increase productivity. Efficient material removal and the ability to produce complex parts in a single setup contribute to cost savings.

Scalability: Suitable for both small-scale and mass production. Turning can be easily scaled to meet varying production demands, from single prototypes to high-volume runs. This flexibility allows manufacturers to adapt to changing market demands and production requirements.

Flexibility: Capable of producing a wide range of part geometries. Turning can be used to create simple cylindrical parts as well as complex shapes, making it a versatile option for many applications. The ability to switch between different operations and tools quickly enhances its adaptability.

Reduced Lead Times: CNC turning, in particular, offers reduced lead times due to its high automation and precision. This enables faster turnaround for parts and products, which is critical in industries with tight deadlines and high demand.

High Precision and Quality: The precision and surface finish achievable with turning can reduce the need for additional finishing processes, further saving time and costs. High-quality parts produced through turning can improve the overall performance and reliability of the final products.

Applications of Turning in Machining

Turning is a versatile machining process with numerous applications across various industries. Here are some examples of how turning is utilized in different sectors.

- Automotive:

Engine components, transmission parts, and other critical parts require precise turning to ensure performance and reliability. Turning is used to produce components such as crankshafts, camshafts, and gears, which are essential for the efficient operation of vehicles.

- Aerospace:

Turbine blades, structural components, and other high-precision parts are often turned to meet strict tolerances and quality standards. Aerospace parts must withstand extreme conditions and stresses, making the precision and reliability of turned components crucial.

- Medical Devices:

Surgical instruments, prosthetic components, and other medical devices require high precision and smooth finishes, which can be achieved through turning. The biocompatibility and accuracy of turned parts are vital for ensuring patient safety and effective medical treatments.

- General Manufacturing:

Custom parts and prototypes are often turned to meet specific design requirements and functional needs. Turning is also used in the production of various consumer goods and industrial equipment, from household appliances to heavy machinery components.

- Energy Sector:

Turning is used to produce parts for power generation and distribution, including components for wind turbines, steam turbines, and electrical generators. These parts require high precision and durability to ensure efficient energy production and distribution.

- Defense and Military:

Turning is employed in the manufacturing of military and defense equipment, such as weapon components, armored vehicle parts, and communication devices. The reliability and precision of turned parts are critical for the performance and safety of military equipment.

Is Turning Right for You?

Deciding whether turning is the right machining process for your needs involves considering several factors. Here are some key points to evaluate.

Material Type: Ensure the material can be effectively machined through turning. Some materials, such as certain plastics or composites, may require specialized turning techniques or tools. Evaluate the machinability and properties of the material to determine its suitability for turning.

Desired Shape: Turning is ideal for cylindrical parts, but with advanced techniques, more complex shapes can be achieved. Evaluate whether the desired geometry can be efficiently produced using turning. Consider the specific features and dimensions required for your part.

Production Volume: Turning is cost-effective for both low and high production volumes. Consider the scale of your production needs and whether turning can meet them efficiently. Assess the potential for scalability and the ability to meet fluctuating production demands.

Required Precision: High precision and smooth finishes are achievable with turning. Assess the required tolerances and surface finishes for your parts and determine if turning can meet these specifications. Evaluate the impact of precision on the performance and quality of the final product.

Trends in Turning Technology

The field of turning continues to evolve, driven by advancements in technology and changing industry needs. Here are some of the latest trends shaping the future of turning.

Integration of AI and IoT:

Enhancing CNC machines with artificial intelligence and the Internet of Things for smarter manufacturing. These technologies enable real-time monitoring, predictive maintenance, and optimization of machining processes, leading to increased efficiency and reduced downtime. AI algorithms can analyze machining data to improve tool paths, reduce cycle times, and enhance part quality.

Advancements in Tool Materials:

Development of more durable and efficient cutting tools. New materials and coatings are being developed to extend tool life, improve cutting performance, and reduce costs. Innovations such as polycrystalline diamond (PCD) and cubic boron nitride (CBN) tools offer superior hardness and wear resistance for difficult-to-machine materials.

Eco-Friendly Cutting Fluids:

Adoption of environmentally friendly lubricants and coolants to reduce environmental impact. These fluids are designed to minimize health risks for operators and reduce waste and pollution. The development of biodegradable and non-toxic cutting fluids is becoming increasingly important in sustainable manufacturing practices.

Automation and Robotics:

Incorporating automation and robotics into turning operations to increase productivity and reduce labor costs. Automated loading and unloading systems, robotic tool changers, and in-process inspection systems are enhancing the efficiency and consistency of turning processes.

Hybrid Machining:

Combining turning with other machining processes, such as milling and grinding, in a single machine. Hybrid machining systems offer greater flexibility and capability, allowing for more complex part geometries and reduced setup times. These systems can perform multiple operations in a single setup, improving overall efficiency and reducing lead times.

Digital Twin Technology:

Using digital twins to simulate and optimize turning operations. Digital twins are virtual models of physical machines and processes that can be used to predict performance, identify potential issues, and optimize machining parameters. This technology enables manufacturers to improve process planning, reduce downtime, and enhance product quality.

Additive Manufacturing Integration:

Integrating additive manufacturing (3D printing) with turning operations to create hybrid manufacturing processes. This approach allows for the production of complex geometries that would be difficult or impossible to achieve with traditional machining alone. Additive manufacturing can be used to build up material, which is then finished with turning to achieve precise dimensions and surface finishes.

Summary

In conclusion, turning is a versatile and essential machining process. Turning has a rich history and continues to evolve with advancements in technology. Its ability to produce high-precision parts with smooth finishes makes it indispensable in various industries, from automotive and aerospace to medical devices and general manufacturing. As trends in AI, IoT, and eco-friendly practices shape the future of turning, staying informed and adapting to these changes will ensure continued success in your machining endeavors.