CNC Lathe Machine with Siemens/Fanuc system

High quality high precision

Good quality and low price, perfect after-sales service

Get price catalog

- Maximum processing diameter: 360-500mm

- Maximum processing length: 300-1250mm

- Spindle speed: 2800-4000 per minute

- Spindle power: 3.7-15kW

CK series

- Maximum processing diameter: 400-1250mm

- Maximum processing length: 550-5000mm

- Spindle speed: 800-2500 per minute

- Spindle power: 5.5-11kW

Consistent Quality Premium Parts from Leading Suppliers

- HT300 one-piece casting bed

- High-precision electric spindle/mechanical spindle

- Servo turret/power turret

- Taiwan's high-precision ball screws and high-rigidity linear guides

Drawing or sample of the part provided and the machine can be selected for you

- Choose processing methods and calculate costs for you

- Has customized the ultimate solution for his business for thousands of manufacturers

You don't need to worry about operating it

- SIEMENS/FANUC system

- Optional multilingual interface

- Free updates forever

All operations and functions are familiar to you

Modelos más vendidos

El modelo de máquina barato y de buena calidad preferido por la mayoría de los clientes

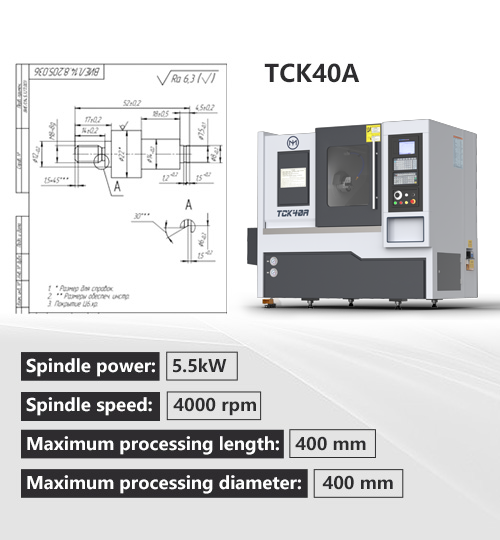

TCK36A

Longitud máx. de procesamiento: 300mm; Diámetro máx. de procesamiento: 360mm; Potencia del husillo: 5.5KW;

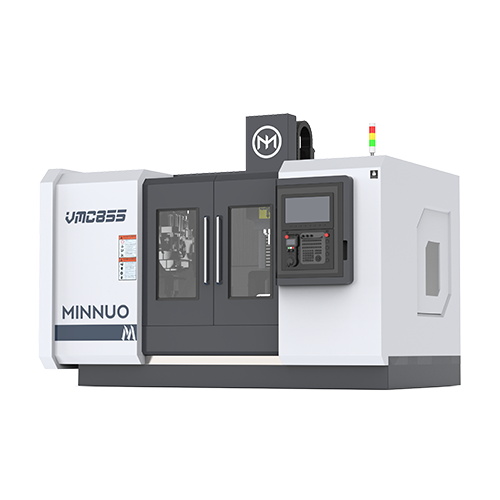

VMC855

Recorrido ejes X, Y, Z: 800x550x550mm; Tamaño del banco de trabajo: 1000x550mm; Velocidad del husillo: 8000r/min;

CK6150

Longitud máx. de procesamiento: 1000mm; Diámetro máx. de procesamiento: 500mm; Potencia del husillo: 7.5/11KW;

Made in China factory, everything is in accordance with ISO9001 standards

30 years of experience in metal processing equipment manufacturing

Tratamiento de muestras

Minnuo

Será su mejor elección para lograr el proceso perfecto

Pre-shipment inspection

Rich experience in export projects, trusted by customers.Delivery at your designated location,We are happy to meet any of your needs.

Choosing the type of machine you want

To select the type of machine tool that meets your requirements, you can consider the following aspects:

- What materials will you be working with? (e.g., metals, plastics)

This helps determine the appropriate cutting tools and machine specifications needed.

- What are the maximum and minimum sizes of workpieces? (e.g., diameter, length)

- What level of precision and tolerance do you require?

- What specific operations do you need the lathe to perform? For example, turning, threading, drilling, or knurling.

- Are there any specific features or attachments you require, such as a digital readout, variable speed control, or specialized chucks? (e.g., variable speeds, digital readout)

- What is your budget for the lathe?

- Do you need any specific after-sales support or service, such as maintenance, training, or warranty coverage?

This ensures the lathe can accommodate your requirements.

This will help in selecting a lathe with the appropriate accuracy and control features.

This will help in choosing a lathe with the necessary capabilities and features.

cost

Shipping and Receiving Support, etc.

Post-delivery service you must be concerned about

WARRANTY

1-year warranty for equipment and 3-year warranty for system

GUIDANCE

Lifetime free 24/7 technical consultation & guidance

TURNKEY

Order more than ten units and get full on-site service from our engineers