PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

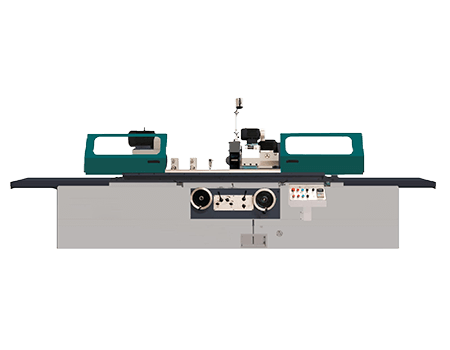

Conventional Manual Cylindrical Grinding Machines M13 Series

Conventional manual cylindrical grinding machine is a kind of machine tool used for precision grinding of the outer surface of cylindrical or conical metal workpieces of small and medium diameters, realizing high-precision and high-finish machining through manual operation, which is widely used in the industries of machinery manufacturing, automobile, aerospace and so on, in order to satisfy the requirements of dimensions and surface quality of the precision parts.

- Max. length ground(O. D): 3000/4000/5000mm

- Dia. Ground(O. D): 50~800mm

- Center height: 500mm

| Specifications | Unit | MW1320 | M1332 | M1332H | M1350 | M1363 | MQ1380A | |

| Machining capacity | Max. length ground(O. D) | mm | 500、750 | 1000、1500 | 2000、3000 | 1500、2000、3000、4000 | 2000、3000、4000、5000 | 3000、4000、5000 |

| Center height | mm | 135 | 180 | 180 | 270 | 370 | 500 | |

| Dia. Ground(O. D) | mm | 8~200 | 8~320 | 8~320 | 25~500 | 30~630 | 50~800 | |

| Max. weight of work piece | Kg | 100 | 150 | 500 | 2000 | 3000 | 3000 | |

| Workhead | Center taper(MT) | MT | 4 | 5 | 5 | 6 | 公制80# | 公制80# |

| Spindle speed /Stepless | r/min | 50HZ:26~260 | 50HZ:19~190 | 50HZ:10~100 | 50HZ:10~100 | 50HZ:6~60 | 50HZ:5~50 | |

| Wheelhead | Max. dimension of wheel(OD×W×ID) | mm | 500×50×203 | 600×75×305 | 600×75×305 | 750×75×305 | 750×75×305 | 900×75×305 |

| Wheel peripheral velocity | m/s | 35 | 35 | 35 | 35 | 35 | 35 | |

| Hand feed per. rev | mm | rough:2 fine:0.5 | rough:2 fine:0.5 | rough:2 fine:0.5 | rough:4 fine:0.5 | rough:4 fine:0.5 | rough:4 fine:0.5 | |

| Hand feed per. gra | mm | rough:0.01 fine:0.0025 | rough:0.01 fine:0.0025 | rough:0.01 fine:0.0025 | rough:0.02 fine:0.0025 | rough:0.02 fine:0.0025 | rough:0.02 fine:0.0025 | |

| Table | Max. swiveling angle of table | Cockwise | 3° | 3° | 3° | 3°(1500)2°(2000、3000) 1°(4000) | 2°(2000) 1°(3000、4000、5000) | 1° |

| Anticlockwise | 9°( 500)8°( 750) | 7°(1000)6°(1500) | 5°(2000)3°(3000) | 6°(1500) 5°(2000)3°(3000) 2°(4000) | 4°(2000) 3°(3000)2°(4000)1.5°(5000) | 3°(3000) 2°( 4000)1.5°(5000) | ||

| Longitudinal speed range of table | m/min | 0.1~4 | 0.1~4 | 0.1~3 | 0.1~3 | 0.1~2.5 | 0.1~2.5 | |

| Tailstock | Center tape | MT | 4 | 4 | 5 | 6 | metric80# | metric80# |

| Quill travel | mm | 30 | 30 | 30 | 70 | 70 | 70 | |

| Motor | Wheelhead motor power | Kw | 5.5 | 11 | 11 | 15 | 22 | 22 |

| Workhead motor power | Kw | 1.1 | 1.5 | 3 | 4 | 15 | 15 | |

| Machining accuracy | Roundness | μm | 2 | 2.5 | 3 | 2.5(1500)3(2000、3000、4000) | 3 | 3 |

| Cylindricity | μm | 5(500)8(750) | 8 | 8 | 8( 1500、2000、3000)12(4000) | 8(2000、3000)12(4000、5000) | 8(3000) 12(4000、5000) | |

| Roughness | μm | Ra0.2 | Ra0.2 | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 | |

| Machine | Gross weight | t | 3( 500)3.3(750) | 4(1000)4.6(1500) | 6.2(2000)7.3(3000) | 9.5(1500) 10.5(2000)11.8(3000) 14(4000) | 18(2000) 22(3000)21(4000) 23.5(5000) | 22(3000)23(4000)25(5000) |

| Packing dimension | cm | 235×203×205 (500) | 326×190×205 (1000) | 580×190×205 (2000) | 543×225×210(1500) | 720×240×226(2000) | 876×240×230(3000) | |

| 583×225×210(2000) | 876×240×226(3000) | 1100×240×230(4000) | ||||||

| 275×203×205 (750) | 426×190×205 (1500) | 780×190×205 (3000) | 796×225×210(3000) | 1100×240×226(4000) | 1270×240×230 (5000) | |||

| 996×225×210(4000) | 1270×240×226(5000) | |||||||

Features

Conventional manual cylindrical grinder is characterized by high cutting precision, high rigidity and high efficiency. It is suitable for grinding cylindrical and conical workpieces.

Manual cylindrical grinding machine composition machine tool workpiece, external grinding wheel, internal grinding wheel, oil pump and cooling pump are driven by independent motors.

- The left and right guide rail adopts P-V structure, which is scraped by high precision manual, so that the whole system products have high precision and high stability.

- The front and rear feed guide rail of grinding wheel can choose roller and wire rail structure.

- M1350, M1363 series worktable and grinding wheel guide rail adopts high stable hydrostatic guide rail, high rigid dynamic and static pressure spindle.

- Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt to chuck grinding internal and external conical workpiece.

Applications

- Conventional manual cylindrical grinders are mainly used for precision machining of shafts, rods and other cylindrical or conical metal parts in machinery manufacturing, automotive, aerospace, bearing manufacturing and other industries.

Standard accessories:

- Cooling water tank

- External circle dresser

- Grinding wheel chuck and handling tools

- Standard grinding wheel

- Balance shaft

- Leveling pad iron

- Working light

- Open center frame

- Center

- Internal round abrasives (onlyM14 series)

Optional accessories:

- Grinding wheel balancing frame

- Magnetic separation

- Paper bag filter

- Closed center frame

- Device end dresser

- Device circular dresser

- Grinding center device

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com