Internal Cylindrical Grinding Machine

Providing cost-effective internal grinding machine equipment at reasonable prices with excellent high precision and rigidity, choose Minnox to make the grinding process more efficient and smarter!

PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Related News

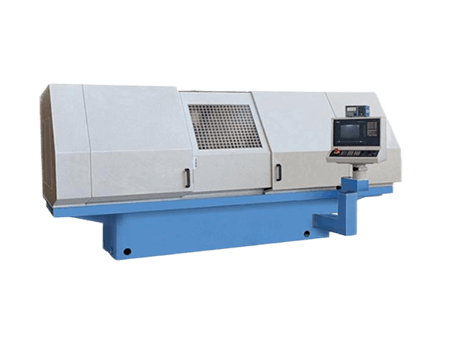

Internal Cylindrical Grinding Machine

Internal Cylindrical Grinding Machine is a grinding machine specializing in the processing of internal circles, which is mainly used for processing high-precision parts. Its working principle is to fix the workpiece through the fixture, and then make the grinding head move along the inner circle of the workpiece to smooth the surface of the workpiece and remove the burr, so as to achieve the purpose of machining sharp edges and corners.

Internal grinding machine mainly consists of spindle, cooling device, grinding wheel head, table, feeding device and machine body. Among them, the spindle is the core part of the grinder, which drives the grinding wheel head to rotate through the motor and controls the rotating speed and direction of the grinding wheel head. The cooling device is used to cool down the grinding wheel, grinding head and workpiece and prevent heat deformation. The working table is used to fix the workpiece, and can be adjusted in height to meet the processing requirements of different workpieces. The feed device is used to control the distance between the grinding wheel head and the workpiece to realize the control of machining accuracy.

How We Support You Before Your Purchase Decision ?

Technical Support

Our team provides comprehensive technical support tailored to your machining needs. We offer the best solutions and recommendations to help you optimize your production processes and increase efficiency.

Quick Response

Our sales team is committed to responding to your inquiries within 24 hours. We promptly address your questions and concerns to ensure you have all the information you need.

Customized Solutions

We offer customized product configurations and solutions based on your specific requirements. Whether you need special attachments, software, or unique configurations, we are here to meet your specific machining needs.

Professionalism and Integrity

With years of industry experience, our professional team is dedicated to providing you with the highest quality pre-sales service. We uphold the values of professionalism and integrity, ensuring you receive reliable and trustworthy support.

Why Choose MINNUO Machine Tools ?

Minnuo Group Co., Ltd. has established two modern industrial bases covering an area of 200,000 square meters.These bases focus on the research, development, and manufacturing of CNC machine tools, flexible manufacturing systems, automated complete sets of technology and equipment, as well as the industrialization of functional components. The current equipment inventory comprises nearly 2500 units of equipment, including “primary, large, precision, and rare” categories, along with over 80 effective patents. The company serves over 100 countries and regions globally in industries such as automobiles, rail transit, construction machinery, oil machinery, mining and metallurgy, communication equipment, and vocational education, providing high-quality products, services, and comprehensive solutions.

Our Manufacturing Process and Quality Control

- 1. Rigorous Quality Checks at Every Stage

- 2. State-of-the-Art Manufacturing Facilities

- 3. Skilled Technicians and Engineers