PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

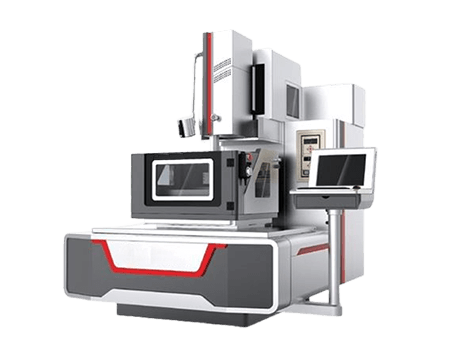

Reciprocating Medium-Wire Cutting Machine DK77HA Series

The reciprocating medium-wire cutting machine DK77HA series offers a fifth axis for rotary cutting, enhancing versatility. It features adjustable wire speed via a frequency converter for smooth operation and PLC-controlled wire transport for customized strokes. The machine ensures streak-free cutting, improving workpiece surface quality.

- Worktable size:580*880mm

- X,Y axis travel:500*600mm

- Max. cut thickness Z: 350mm

Specifications | Unit | DK7732HA | DK7740HA | DK7750HA |

Worktable size | mm | 390*615 | 480*720 | 580*880 |

X,Y axis travel(X*Y) | mm | 320*400 | 400*500 | 500*600 |

Max. cut thickness Z | mm | 300 | 300 | 350 |

U,V axis travel | mm | 60*60 | ||

Diameter of Mo. wire | mm | Molybdenum wire φ0.12~φ0.18 | ||

Wire speed |

| 7-speed adjustable | ||

Taper angle/ workpiece thickness | ° / mm | 3°/60mm | ||

Process accuracy( vertical) | mm | Multi- cut: 10×10×30 Squire≤0.006 | ||

Process roughness | μm | Multi- cut: Ra≤1.2 | ||

Motor drive system |

| Stepper motor(Option: Servo motor) | ||

Screw & Guides(X,Y) |

| Precision ball screw/ Linear motion guides | ||

Wire tension |

| Precision spring automatic tensioning mechanism | ||

Working fluid/ capacity | L | Complex or water-soluble special coolant/65L | ||

Power supply |

| AC 3-φ380V 2KW | ||

Max. table carry | kg | 300 | 400 | 500 |

Net weight | kg | 1600 | 1800 | 2500 |

Dimensions | mm | 1600*1250*2180 | 1850*1500*2200 | 2100*1800*2400 |

Features

The reciprocating medium-wire cutting machine DK77HA series provides a fifth axis for advanced cutting capabilities. It includes a frequency converter for infinite wire speed adjustment, PLC control for arbitrary wire stroke setting, and a precision spring automatic tensioning mechanism. This ensures efficient, quiet operation and high surface finish on workpieces, along with customizable cutting parameters for various applications.- Adds a fifth axis to the X, Y, U and V axi Realize workpiece rotary cutting processing.

- The wire transportation adopts frequency converter to realize infinite adjustment of the speed of wire walking, and low noise and smooth operation.

- The wire transportation adopts PLC control to realize the deformation range reciprocating wire walking, and the forward and reverse wire walking stroke can be set arbitrarily.

- Streak-free cutting is realized to improve the surface quality of the processed workpiece.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com