Heavy Duty Lathe

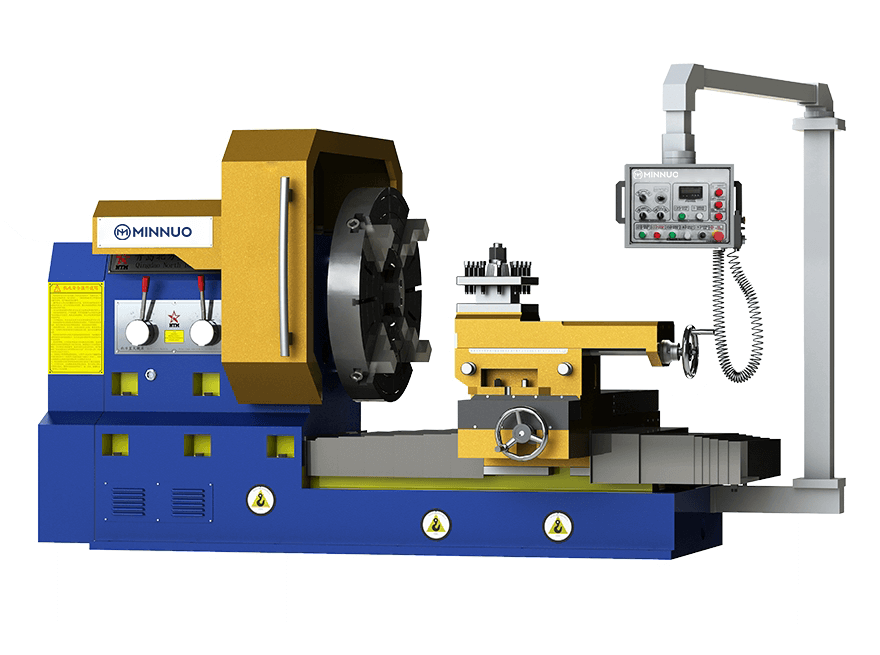

High Efficiency, High Precision, Stable Heavy Duty Horizontal CNC Lathe Machine

Minnuo,a leading manufacturer in China with 37 years of experience.To provide you with unparalleled machining accuracy and production efficiency to meet the processing needs of various complex parts.

PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Related News

Heavy Duty Lathe

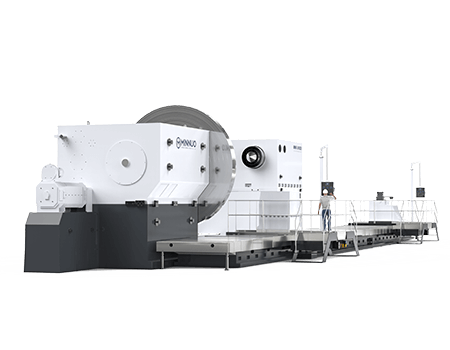

Heavy duty lathe is a machine tool within the range of 30~100 tons, which is a workhorse with the advantages of high precision, high efficiency, high automation and high flexibility in the machinery manufacturing equipment. It has a wide range of process performance, can process straight line cylindrical, oblique cylindrical, arc and all kinds of threads.

Heavy Duty Horizontal CNC Lathe Machine Structure Feature

1.

The machine bed is made of high-grade, high-quality gray cast iron using resin sand molding and features a sand-sealed structure. The guideways are of a dual-guide rectangular flat type, and they are ground on high-precision guideway grinding machines, ensuring the machine tool guideways have a high degree of precision. The upper width of the machine bed is 1100mm, and chip removal is done from the rear.

2.

The structure of the main components of the machine tool is designed and analyzed using finite element analysis, ensuring excellent dynamic and static characteristics, and achieving an optimized state. All main castings are made using resin sand molding and high-strength, low-stress cast iron melted in a power frequency furnace. These components undergo multiple stress relief processes, such as annealing and vibration aging, to eliminate stress. This process results in the machine tool achieving ideal rigidity, minimizing material and structural stress, and ensuring long-term stability of the machine’s accuracy.

3.

The headstock and feed box are machined on imported CNC milling and boring machines and machining centers, ensuring strict control over roundness, coaxiality, and axial parallelism. The spindle uses a three-support structure with precision spindle bearings. The speed change gears undergo high-frequency quenching and grinding processes, and tooth tip modification techniques are employed. The headstock is lubricated with powerful oil fluid, and the front end of the spindle features a reliable labyrinth seal mechanism, effectively preventing oil leakage and the entry of foreign objects into the headstock.

4.

The tailstock consists of an upper and a lower body. The upper body contains the tailstock spindle and the spindle centerline adjustment mechanism. The lower body houses the rapid movement mechanism and the locking mechanism. The tailstock sleeve uses a built-in center structure, and a disc spring is installed at the rear of the spindle to prevent damage from workpiece thermal expansion. The tailstock rapid movement mechanism is driven by a separate motor.

client demand

After receiving your company’s processing requirements, we conducted a careful study and discussion of the project and formulated a detailed technical program to ensure that our products and programs can meet your company’s requirements.

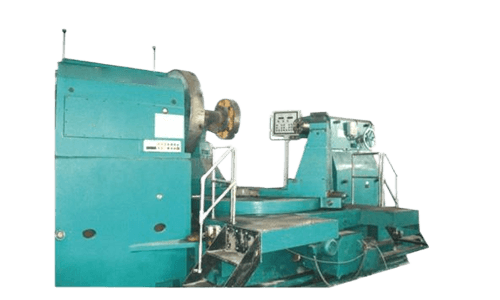

CKW61100 series CNC mandrel lathe

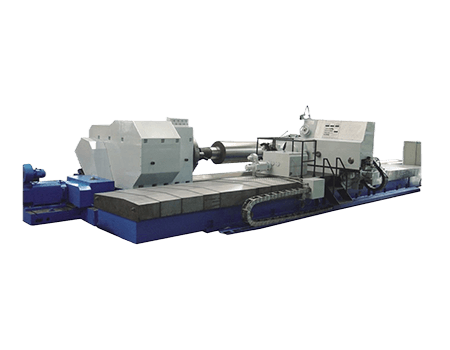

CCK61400×18000mm×150T CNC Heavy Duty Horizontal Lathe

2017.4.17-22 Beijing Exhibition Exhibition Machine

CW61250×8000mm/10T large horizontal lathe technical program

We work together with our customers on machine selection, process, fixture and tooling concepts, and provide them with complete cutting technology solutions.

How We Support You Before Your Purchase Decision ?

Technical Support

Our team provides comprehensive technical support tailored to your machining needs. We offer the best solutions and recommendations to help you optimize your production processes and increase efficiency.

Quick Response

Our sales team is committed to responding to your inquiries within 24 hours. We promptly address your questions and concerns to ensure you have all the information you need.

Customized Solutions

We offer customized product configurations and solutions based on your specific requirements. Whether you need special attachments, software, or unique configurations, we are here to meet your specific machining needs.

Professionalism and Integrity

With years of industry experience, our professional team is dedicated to providing you with the highest quality pre-sales service. We uphold the values of professionalism and integrity, ensuring you receive reliable and trustworthy support.

Why Choose MINNUO Machine Tools ?

Minnuo Group Co., Ltd. has established two modern industrial bases covering an area of 200,000 square meters.These bases focus on the research, development, and manufacturing of CNC machine tools, flexible manufacturing systems, automated complete sets of technology and equipment, as well as the industrialization of functional components. The current equipment inventory comprises nearly 2500 units of equipment, including “primary, large, precision, and rare” categories, along with over 80 effective patents. The company serves over 100 countries and regions globally in industries such as automobiles, rail transit, construction machinery, oil machinery, mining and metallurgy, communication equipment, and vocational education, providing high-quality products, services, and comprehensive solutions.

Our Manufacturing Process and Quality Control

- 1. Rigorous Quality Checks at Every Stage

- 2. State-of-the-Art Manufacturing Facilities

- 3. Skilled Technicians and Engineers

Comprehensive After-Sales Service

Our heavy duty lathe have a complete after-sales service system.