PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

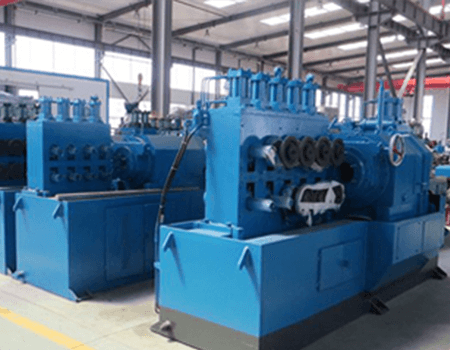

CNC Centerless Lathe WXC Series

The WXC series of centerless lathes represents a new generation of highly efficient specialty lathes designed for the cylindrical machining of slender shafts, tubes, and other round metal bars. This state-of-the-art machine not only quickly eliminates surface defects such as decarburized layers and cracks, but also provides excellent accuracy and surface finish. It is particularly adept at handling extra-long round steel, which can significantly increase productivity by several times to an order of magnitude over conventional machining methods.

- Diameter range: 6.5~710mm

- Workpiece length: 1400mm

- Tensile strength: ≤1100Mpa

Features

- The CNC type is controlled by PLC multi-point control, which can realize automatic tool adjustment without stopping and on-line electric tool adjustment.

- According to the small changes in the diameter of the processed material to realize closed-loop online fully automatic material diameter control, significantly improve the processing accuracy and efficiency.

- The CNC structure is a combination of mechanical, electrical and hydraulic, with high degree of automation, fast efficiency and more convenient operation.

Applications

- Centerless lathe WXC series should be mainly used in the production of bright material, silver bright steel, but also can be used in machinery manufacturing, automobile parts, bearing production, spring manufacturing, military enterprises, the production of slender shafts, titanium rods, copper rods, aluminum rods, magnesium rods and other non-ferrous metal rods and tubes, and other machinery and equipment manufacturing of the preparation process.

| Model | WXC30C | WXC40C | WXC60B | WXC60C | WXC80C | WXC100CA | WXC100C | WXC130C | WXC130CA | WXC160C | WXC200B | WXC200C | WXC255C | WXC350C | WXC400C | WXC500C | WXC700C | |

| Workpiece requirements | Diameter range (mm) | 6.5<dia<31 | 11<dia<40 | 15<dia<62 | 15<dia<63 | 21<dia<83 | 25<dia<105 | 26<dia<105 | 35<dia<130 | 36<dia<135 | 55<dia<165 | 85<dia<205 | 85<dia<205 | 100<dia<255 | 150<dia<360 | 205<dia<410 | 315<dia<510 | 405<dia<710 |

| Workpiece length (mm) | ≥1400 | ≥1400 | ≥ 2000 | ≥2200 | ≥2200 | ≥2800 | ≥2200 | ≥2800 | ≥2800 | ≥3500 | ≥2800 | ≥2800 | ≥3500 | ≥4000 | ≥4000 | ≥4000 | ≥4000 | |

| Tensile strength (Mpa) | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | ≤1100 | |

| Surface hardness | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | ≤HB320 | |

| Straightness (mm/m) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | |

| Diameter Tolerance | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | according to GB 702-2004 second group | |

| Roundness(mm) | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | ≤50% of diameter tolerance | |

| Surface roughness (Ra) | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | ≤25~50μm | |

| Finished product | Diameter range (mm) | 6≤dia≤30 | 10≤dia≤39 | 14≤dia≤60 | 14≤dia≤60 | 20≤dia≤80 | 25≤dia≤101 | 25≤dia≤101 | 35≤dia≤125 | 35≤dia≤130 | 55≤dia≤160 | 85≤dia≤200 | 85≤dia≤200 | 100≤dia≤250 | 150≤dia≤350 | 200≤dia≤400 | 315≤dia≤500 | 405≤dia≤700 |

| Diameter cutting capacity (mm) | 0.5~1.0 | 0.5~2.0 | 0.5~2.0 | 0.5~2.0 | 0.5~3 | 1.0~4.0 | 1.0~4.0 | 1.0~5.0 | 1.0~5.0 | 1.0~5.0 | 1.0~5.0 | 1.0~5.0 | 1.0~5.0 | 1.0~10.0 | 1.0~10.0 | 1.0~10.0 | 1.0~10.0 | |

| Diameter tolerance | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | ≤h10 | |

| Surface roughness (Ra) | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | ≤6.3μm | |

| Travel speed (m/min) | 1.0~8.0 | 1.0~10.0 | 1.0~7.0 | 1.0~8.0 | 1.0~8.0 | 0.5~8.0 | 0.5~7.0 | 0.2~3.0 | 0.2~4.0 | 0.2~3.0 | 0.2~2.0 | 0.2~3.0 | 0.1~1.5 | 0.1~1.2 | 0.05~1.0 | 0.05~1.0 | 0.05~0.5 | |

| Cutter speed (rpm) | 900~2000 | 900~2400 | 440~1200 | 440~1300 | 430~1200 | 430~1000 | 430~1000 | 110~660 | 110~660 | 110~440 | 65~360 | 100~400 | 70~360 | 36~255 | 20~240 | 20~160 | 14~112 | |

| Main motor (kw) | 30 | 45 | 45 | 45 | 55 | 75/95 | 55/75 | 90 | 90/110 | 90/110 | 90/110 | 90/110 | 132 | 160 | 200 | 200 | 355 | |

| Total power (kw) | 50 | 65 | 65 | 65 | 75 | 95/110 | 75/95 | 115 | 115/135 | 120/140 | 120/140 | 120/140 | 172 | 225 | 285 | 290 | 455 | |

| Compressed gas source (user-provided) | 0.5~0.8MPa、1.8m3/min、0.8 m3or more storage tank, with secondary oil-water separator and compressed air refrigerated dryer | |||||||||||||||||

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com