PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

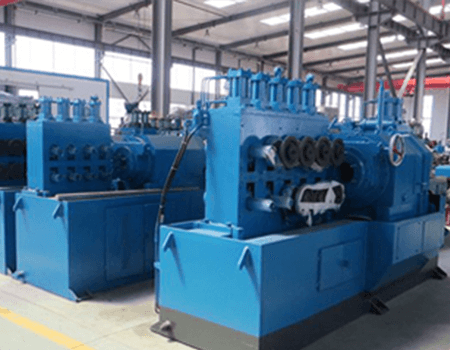

Centerless Lathe MCT Series

Centerless lathes are mainly used for processing the outer skin of various long circular metal materials such as metal bars, pipes, and wires. They can quickly and efficiently remove decarburization layers and cracks on the surface of the bars, and have many advantages such as stable feed, accurate bar centering, fast speed, and low tool wear.

- Processing range(mm): Φ6-Φ500

- Speed(m/min): 0.2-26

- Surfaceness: Ra≤3.2

Features

- CNC centreless lathe is practical, inexpensive, stable machining process, fast speed, high efficiency, good quality, the whole line of equipment semi-automatic control, splitter box cardan shaft drive, suitable for a variety of process environments.

- Fast machining speed: Compared with the common process, it is more efficient, faster and more accurate, can quickly and effectively remove the decarburized layer and cracks on the surface of the bar, and has many advantages, such as stable feeding, accurate centering of the bar, fast speed, and low wear of the tool;

- Increase production: Since the round steel peeling machine can directly peel the long material, eliminating intermediate processes such as breaking material, it greatly improves the production.

- MCT-A type is centerless machine tool with front and rear clamping: economical and practical, high reliability.

- MCT-B type is centerless machine tool with pull-out trolley: the processed material is pulled out without indentation to increase the speed.

Applications

- CNC centerless lathes can be used for the production of bright materials and silver-bright steels in a wide range of models from 6 mm to 500 mm full section.

- It is widely used in the preparation process of mechanical equipment manufacturing such as machinery manufacturing, hydraulic cylinders, non-ferrous metals, titanium alloys, wind power generation, vehicle manufacturing, bearing manufacturing, spring manufacturing, military enterprises, slender shaft production, etc. The performance is stable and the quality is reliable.

| Model | Processing range(mm) | Speed(m/min) | Depth of cutting(mm) | Surfaceness | Ovality | Power |

| MCT-20A | Φ6-Φ20 | 1-26 | 0.5-2 | Ra≤3.2 | ≤0.05 | 22KW |

| MCT-30A | Φ7-Φ30 | 1-18 | 0.5-2 | Ra≤3.2 | ≤0.05 | 30KW |

| MCT-40A | Φ8-Φ40 | 1-12 | 0.5-2 | Ra≤3.2 | ≤0.05 | 37KW |

| MCT-40B | Φ8-Φ40 | 1-14 | 0.5-2 | Ra≤3.2 | ≤0.05 | 37KW |

| MCT-60A | Φ14-Φ65 | 1-8 | 0.5-2 | Ra≤3.2 | ≤0.05 | 37KW |

| MCT-60B | Φ14-Φ65 | 1-10 | 0.5-2 | Ra≤3.2 | ≤0.05 | 37KW |

| MCT-80A | Φ20-Φ85 | 1-8 | 0.5-4 | Ra≤3.2 | ≤0.05 | 45KW |

| MCT-80B | Φ20-Φ85 | 1-10 | 0.5-4 | Ra≤3.2 | ≤0.05 | 45KW |

| MCT-100A | Φ25-Φ105 | 1-6 | 1-4 | Ra≤3.2 | ≤0.06 | 55KW |

| MCT-100B | Φ25-Φ105 | 1-8 | 1-4 | Ra≤3.2 | ≤0.06 | 55KW |

| MCT-130A | Φ30-Φ130 | 1-4 | 1-5 | Ra≤3.2 | ≤0.07 | 75KW |

| MCT-130B | Φ30-Φ130 | 1-6 | 1-5 | Ra≤3.2 | ≤0.07 | 75KW |

| MCT-165A | Φ60-Φ165 | 0.4-4 | 1-5 | Ra≤3.2 | ≤0.08 | 90KW |

| MCT-165B | Φ60-Φ165 | 0.4-4 | 1-5 | Ra≤3.2 | ≤0.08 | 90KW |

| MCT-200A | Φ80-Φ200 | 0.3-3 | 1-5 | Ra≤3.2 | ≤0.10 | 110KW |

| MCT-200B | Φ80-Φ200 | 0.3-5 | 1-5 | Ra≤3.2 | ≤0.10 | 110KW |

| MCT-250A | Φ100-Φ260 | 0.2-2 | 1-5 | Ra≤3.2 | ≤0.10 | 132KW |

| MCT-250B | Φ100-Φ260 | 0.2-3 | 1-5 | Ra≤3.2 | ≦0.10 | 132KW |

| MCT-300A | Φ150-Φ300 | 0.2-1 | 1-8 | Ra≤3.2 | ≦0.10 | 160KW |

| MCT-300B | Φ150-Φ300 | 0.2-1.5 | 1-8 | Ra≤3.2 | ≦0.10 | 160KW |

| MCT-350A | Φ180-Φ360 | 0.2-1 | 1-8 | Ra≤3.2 | ≦0.10 | 200KW |

| MCT-350B | Φ180-Φ360 | 0.2-1.5 | 1-8 | Ra≤3.2 | ≦0.10 | 200KW |

| MCT-400B | Φ220-Φ400 | 0.2-1.5 | 1-8 | Ra≤3.2 | ≦0.10 | 250KW |

| MCT-500B | Φ300-Φ500 | 0.2-1.5 | 1-10 | Ra≤3.2 | ≦0.10 | 315KW |

The configuration of all the above models can be selected according to customer requirements, such as: electrical, hydraulic, pneumatic, motor and so on. You can contact us if you want to know more about centerless lathe!

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com