PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

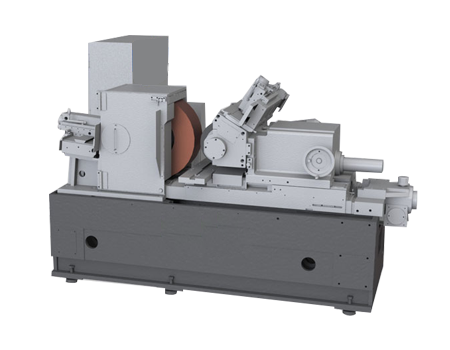

Centreless Grinding Machine BC200 BC300 BC400 BC1040 BC1808 BC6030 BC6040

The centreless grinding machines of this series are suitable for plunge-cut grinding due to the high rigidity of the grinding wheels and guide spindles; they can be equipped with an optional profiling dresser, a single-point diamond dresser and a diamond roller dresser; they are suitable for plunge-cutting and pass-through grinding of workpieces with a diameter range of 0.5-150 mm. The maximum cutting width is up to 400 mm.

- Range of grinding diameters: 1.5-150mm

- Maximum length of plunge-cut grinding: 120-400mm

- Grinding wheel diameter: 610mm

- Guide diameter: 350mm

- Grinding wheel motor power: 7.5-45kw

- Guide wheel motor power: 1.1-4kw

| Specifications | Unit | BC200 | BC300 | BC400 | BC1040 | BC1808 | BC6030 | BC6040 | |

| Processing range | Grinding diameter | mm | Φ1.6~Φ120 | Φ1.6~Φ120 | Φ1.6~Φ120 | Φ0.5~Φ40 | Φ1~Φ50 | Φ1.5~Φ150 | Φ1.5~Φ150 |

| Maximum diameter of plunge-cut grinding | mm | 200 | 300 | 300 | 120 | 200 | 400 | 400 | |

| Grinding feed | Framework | Plastic guideway + ball screw | Linear guides + rolling screws | ||||||

| Drive units | servo motor | ||||||||

| Minimum feed | mm | 0.001 | |||||||

| Grinding wheel spindle | Framework | Single support rolling bearings | Double-supported rolling bearings | Double-supported bearing/shaft tile | |||||

| RPM | rad/min | 1400 | |||||||

| Power | kw | 15 | 35 | 45 | 7.5 | 11 | 35 | 45 | |

| Rotary axis | level | ° | ±3 | ||||||

| lean | ° | ±6 | |||||||

| Guide wheel spindle | Framework | Double-support rollingbearings | Double support bearings | ||||||

| RPM | rad/min | 20-200stepless speed regulation | |||||||

| Power | kw | 2.2 | 2.2 | 3 | 1.1 | 1.5 | 2.2 | 4 | |

| Tool Size | Grinding wheel | mm | 610*205*304.8 | 610*305*304.8 | 610*305*304.8 | 610*405*304.8 | 610*405*304.8 | 610*305*304.8 | 610*405*304.8 |

| Guide wheel | mm | 350*205*203.2 | 330*305*203.2 | 330*305*203.2 | 350*405*203.2 | 350*405*203.2 | 330*305*203.2 | 350*405*203.2 | |

| pallet | Cemented carbide | ||||||||

| Central Expressway | mm | 1085 | 1100 | ||||||

| Grinding Wheel Dresser | Reciprocating/Cutting | CNC/CNC | Speed control motors / CNC | ||||||

| Feed accuracy | mm | 0.001 | |||||||

| Guide Wheel Dresser | Reciprocating/Cutting | Speed control motors/manual | |||||||

| Feed accuracy | mm | 0.01 | |||||||

| Machine data | Mainframe area | mm | 2500*1050 | 3300*1662 | |||||

| Machine height | mm | 1600 | 2027 | ||||||

| Machine weight | kg | 7000 | 7500 | 7500 | 8800 | 8800 | 7800 | 8800 | |

| Operating system | Siemens/Fanuc | Mitsubishi | Siemens/Fanuc | ||||||

Features

- The two-axis CNC dresser can accurately dress steps, curves, arcs and other grinding wheel shapes, and at the same time, it can store multiple sets of dressing programmes to match different workpieces, making it easy to change types.

- The combination of servomotor and ball screw effectively ensures sensitive and precise feeding, which significantly reduces the dimensional dispersion of the ground workpiece.

- The guide wheel main drive with rolling bearings provides reliable rigidity during grinding by applying a preload during assembly.

Applications

- Compact and efficient centreless grinding machines for mass production of small and medium-sized precision parts.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com