PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

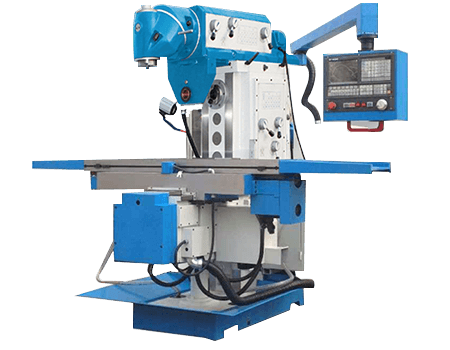

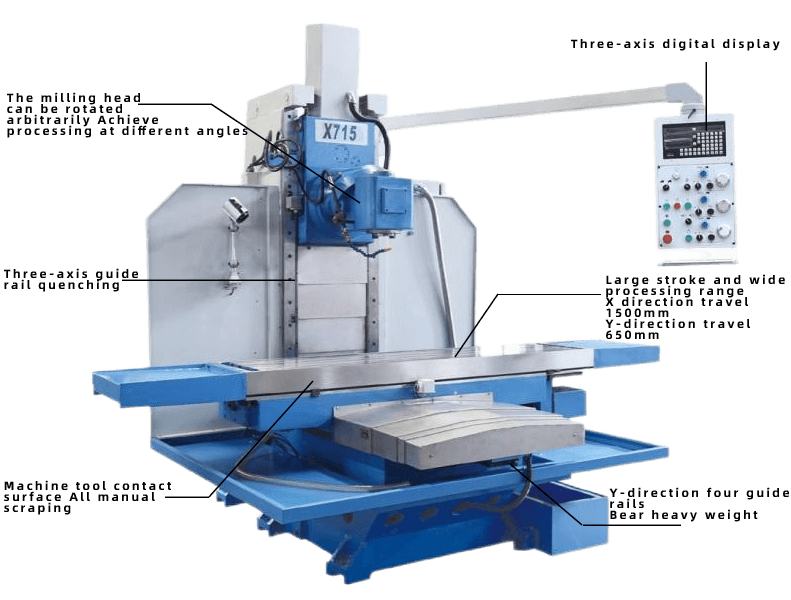

CNC Bed Type Milling Machine XK715/XK716 Series

CNC bed type milling machine XK715/XK716 series, is a vertical and horizontal type, the machine itself is characterized by heavy cutting, high rigidity and large travel. The table cannot be lifted and lowered, but can be moved longitudinally and transversely along the bed guideway, and the milling head or column can be moved vertically.

- Table size: 2500*600mm

- Table travel-X: 1800mm

- Table travel-Y: 700mm

Specification | Units | XK715 | XK716 |

Spindle hole taper |

| 7:24ISO 50 | |

Spindle speed range | r/ min | Two stage stepless 6-300, 30-1500 | |

Distance between spindle axis and column guideway | mm | 610 | 8-660 |

Distance between spindle nose and table surface(V) | mm | 10-650 | 10-700 |

Distance between spindle axis and table surface(H) | mm | 8-660 | |

Table size | mm | 2100*500 | 2500*600 |

T slots | mm | 4/20/100 | 5/20/100 |

Table travel-X | mm | 1500 | 1800 |

Table travel-Y | mm | 650 | 700 |

Table feed-X/Y | mm/min | 2.5-3000 | |

Table feed-Z | mm/ min | 2.5-2500 | |

Table rapid feed X/Y/Z | mm/ min | 6000/6000/3000 | |

Main motor power | kw | 11 | |

Torque of X/Y/Z axis AC serve motor | Nm | 18/23/18 | |

Cooling pump motor power | W | 90 | |

Overall size | mm | 3220*2420*2800 | 4380*2520*2800 |

Net weight | kg | 7300 | 9000 |

Features

CNC bed type milling machine with CNC rotary table can be used both vertically and horizontally. For bar machining, the rotary table is fixed vertically on the working table, and fixed on the indexing head by chuck and tailstock clamping to realize the function of automatic indexing at various angles of 360°. This kind of clamping method, the setting unit is 0.001°, supports four-axis and four-link function.- Universal rotary head: the milling head can be manually rotated to any angle, vertical and horizontal dual-use, to meet a variety of angular processing, vertical milling head can be milling and drilling, horizontal milling can be mounted on the bracket can be bored, the spindle for the ISO50 type, to meet the requirements of heavy cutting.

- Cage for horizontal milling: The front part of the milling machine is equipped with cage for horizontal milling, which is convenient for the processing of large workpieces with good accuracy retention.

- Working table: the working table area is 2500X600MM, suitable for large workpiece processing, X-square stroke 1800MM, Y-square stroke 700MM, suitable for heavy-duty workpiece processing, processing length is long.

- Adopting gear transmission, two gears infinitely variable speed, wide range of speed change, to meet the requirements of different materials processing.

- The base, slide, table, column, spindle box and other major basic parts are made of HT300 cast iron and treated by artificial aging, which makes the machine stable for long-term use and provides a guarantee for the stability of the machine performance.

- The machine operating system can complete high precision milling such as straight line and circular arc at any angle, and drilling and reaming can be carried out. Rich NC functions; such as color LCD display, functions, tool compensation, program storage and editing, machining track three-dimensional graphics. It is not only suitable for milling machining but also for high precision surface machining.

Applications

- CNC bed-type milling machine is a new type of general-purpose bed-type machine tool developed by our company, with reasonable structure, good rigidity, high precision, and various functions such as milling, drilling, tapping, reaming and reaming, etc. It is an ideal processing equipment for machinery, electronics, instruments, meters, molds, automobiles and other industries.

Configuration

- Standard accessories:

- SIEMENS808D

- Optional accessories:

- 4th axis CNC rotary table

- CNC indexing head

- CNC system: FANUC, Mitsubishi, GSK980MDC

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com