PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

CNC Lifting Table Milling Machine XK6040 Series

CNC horizontal lifting table milling machine CNC rotary table, can be used both vertically and horizontally. For bar machining, the rotary table is fixed vertically on the working table, and fixed on the indexing head by chuck and tailstock clamping to realize the function of automatic indexing at various angles of 360°. This kind of clamping method, the setting unit is 0.001°, supports four-axis and four-continuous motion function.

- Table size: 1700*400mm

- T slots ( N/W/D): 3/18/90mm

- Longitudinal/Cross/Vertical travel: 1000/350/360mm

| Specification | Units | XK6040 | XK6032 |

| Table size | mm | 1700×400 | 1600×320 |

| T slots ( N/W/D) | mm | 3/18/90 | 3/18/70 |

| Longitudinal travel | mm | 1000 | 900 |

| Cross travel | mm | 350 | 310 |

| Vertical travel | mm | 360 | 410 |

| Table longitudinal feed ( auto) | mm/min | 6-3200 | |

| Table cross feed ( auto) | mm/min | 6-3200 | |

| Table vertical feed ( auto) | mm/min | 3-1600 | |

| Distance between spindle and table surface | mm | 20-380 | 55-465 |

| Distance from spindle axis to arm | mm | 155 | |

| Spindle hole taper | – | ISO 50(7:24) | |

| Spindle speed step | step | 18 | |

| Spindle speed range | r/min | 30-1500 | |

| Power of spindle motor | kw | 11 | 7.5 |

| Torque of X/Y/Z axis AC se rvo motor | N. m | 15/15/23 | 10/10/18 |

| Overall size | mm | 2550*2160*1800 | 2040*1800*1800 |

| Net weight | kg | 3650 | 2650 |

Features

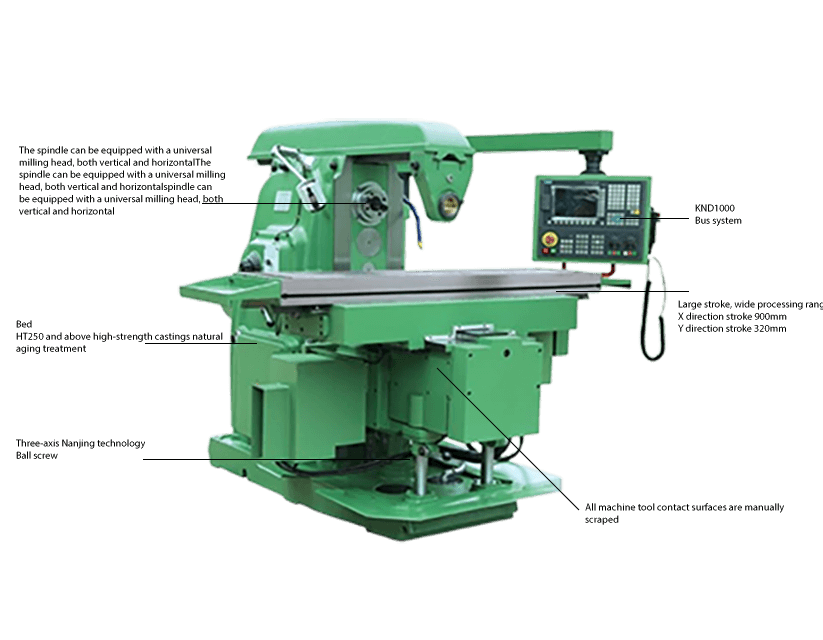

Horizontal CNC milling machine XK6040 series adopts the guide rail surface paste plastic process, the bonding surface is after manual shoveling and scraping process. This model is characterized by heavy cutting, high rigidity, and multiple speeds, and also supports customized full protection functions.

CNC milling machine XK6040 series adopts the guide rail surface paste plastic process, the bonding surface is after manual shoveling and scraping process. This model is characterized by heavy cutting, high rigidity, and multiple speeds, and also supports customized full protection function.

- Spindle: Universal milling head and vertical milling head can be installed to realize universal angle milling function, the noise of the spindle meets the national standard and is strictly controlled within 80 dB, and the vertical milling head can be rotated positively or negatively in the vertical plane and the horizontal range.

- Scraping and researching process: all the combined surfaces of the machine tool have gone through the manual scraping and researching process, which makes the machine tool accurate and has better accuracy retention, and the scraping and researching surface retains the lubricating oil, which guarantees the guide rail is fully lubricated and is durable.

- Gearbox: It adopts an 18-stage gearbox with a wide range of speed changes to meet the requirements of processing different materials.

- Servo motor: A 3-axis servo motor adopts servo motor drive, which can realize infinite speed regulation of feed, good stability, fast response speed, and double the working efficiency.

Applications

- CNC lifting table milling machine is a CNC lifting table milling machine controlled by an electrical system and driven by a servo motor. Mainly suitable for batch production, single-piece mass production, mechanical processing department, and tool repair department. It can process planes, slopes, grooves, holes, gears, etc. of various medium and small parts.

- It is an ideal processing equipment for machinery manufacturing, molds, instruments, meters, automobiles, motorcycles, and other industries.

Related Products

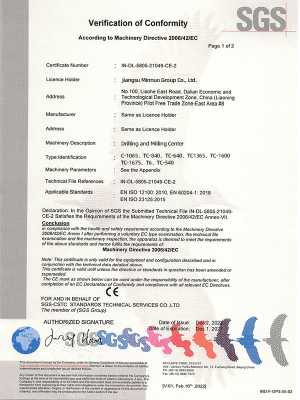

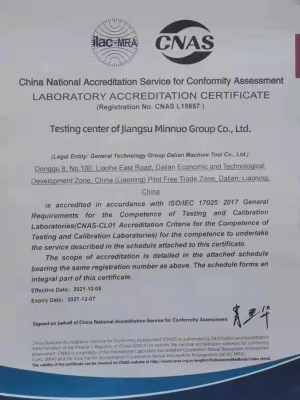

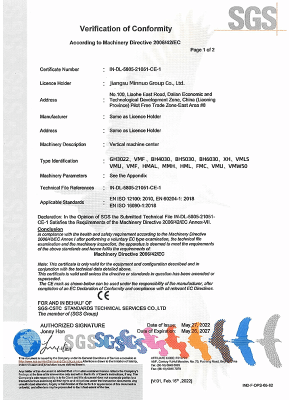

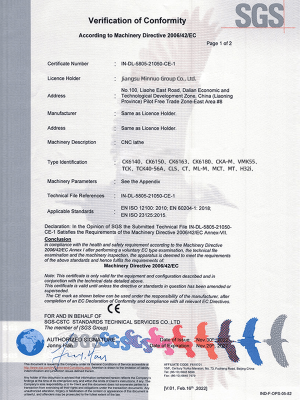

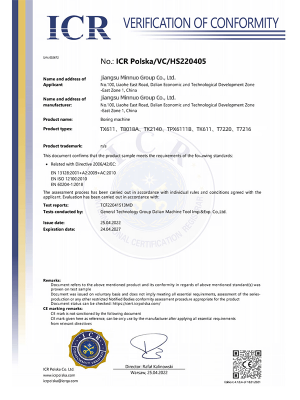

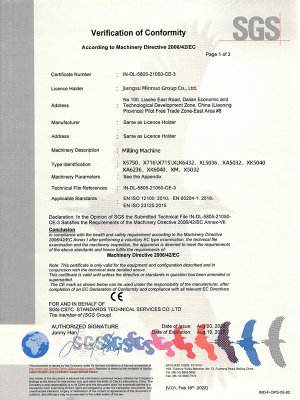

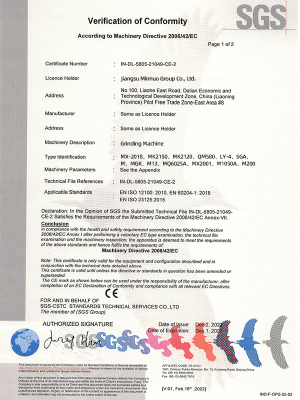

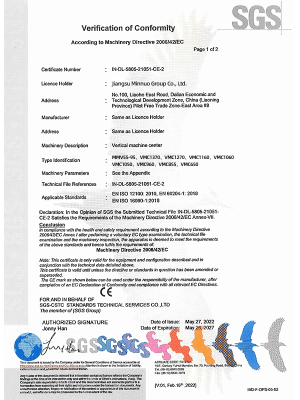

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com