PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

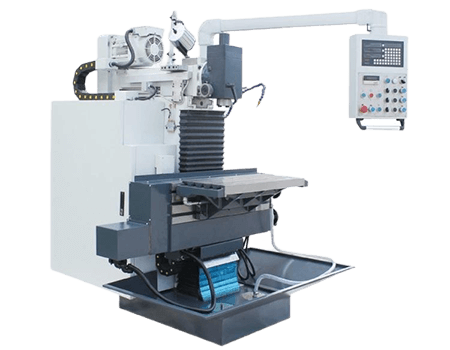

CNC Universal Milling Machine XK6032 Series

CNC universal milling machine adopts CNC rotary table, which can be used both vertically and horizontally. For bar machining, the rotary table is fixed vertically on the working table, and fixed on the indexing head by chuck and tailstock clamping, realizing 360°multi-angle automatic indexing function. This kind of clamping method, the setting unit is 0.001°, supports four-axis four-continuous function.

- Table size: 1600x320mm

- Table load: 300kg

- X/Y/Z travel: 900/310/410mm

Specifications | Unit | XK6032 | XK6032L | XK6032A |

X travel | mm | 700 | 900 | 700 |

Y travel | mm | 300 | 310 | 300 |

Z travel | mm | 350 | 410 | 350 |

Spindle model | mm | ISO50(7:24) | ISO50(7:24) | ISO50(7:24) |

Spindle power | KW | 7.5 | 7.5 | 7.5 |

Spindle transmission | s | Gear Transmission | ||

Spindle speed/stage | rpm | 30-1500/18Step | 30-1500/18Step | 30-1500/18Step |

Table size | mm | 1325×320 | 1600×320 | 1325×320 |

Table load | kg | 300 | 300 | 300 |

X/Y/Z feed speed | Mm/min | stepless | stepless | stepless |

X/Y/Z speed | M/min | 4000/4000/3000 | 4000/4000/3000 | 5000/4000/3000 |

T-slot number/slot width/slot distance | mm | 3/18/70 | 3/18/70 | 3/18/70 |

Distance from spindle centerline to table surface | mm | 75-425 | 55-465 | 75-425 |

Distance from spindle centerline to suspension beam plane | mm | 155 | 155 | 155 |

X/Y/Z servo motor torque | Nm | 2010/10/18 | 2010/10/18 | 2010/10/18 |

Dimensions | mm | 1840x1800x1800 | 2040x1800x1800 | 2370x2500x2250 |

Machine weight | Kg | 2600 | 2650 | 3850 |

Features

- High-precision machining: adopting advanced CNC system and high-rigidity structure to ensure machining precision, improve product quality and solve the problem of unstable precision of traditional manual milling machine.

- Efficient production: automated operation significantly improves the production efficiency, reduces the operation time and labor cost, and effectively solves the problem of cumbersome manual operation and low efficiency.

- Multifunctionality: It can realize a variety of machining operations such as milling, drilling, boring, etc., to meet the completion of one-time clamping of complex parts, and solve the problem of loss of precision and low efficiency brought by multiple clamping of traditional equipment.

- User-friendly: the interface is easy to operate, easy to learn and master, reducing training time and operating difficulty, and solving the user’s concern about the difficulty of operating complex CNC equipment.

- System diversity: we provide a variety of system options, can be optional FANUC OIMF system, Siemens system, Mitsubishi M80 system, wide number of systems, KND1000MC1I bus system and so on.

Applications

- CNC universal milling machine XK6032 series is widely used in machinery manufacturing, mold processing, aerospace and automotive industry. Its high accuracy and versatility make it suitable for machining complex parts, precision molds and small to medium-sized mass production needs. Whether it is difficult milling, drilling or boring operations, XK6032 can provide stable machining results and help enterprises improve production efficiency and product quality, which is the ideal choice for modern workshops.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com