PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

CNC Deep Hole Boring Machine TK2140 Series

CNC deep hole boring machine TK2140 series is a high rigidity, multi-functional machine tool, equipped with external chip removal system and advanced CNC system, capable of realizing powerful boring and rolling machining of deep holes, suitable for precision machining of shaft through holes, blind holes and stepped holes, supporting servo motor drive and wide-frequency AC inverter motors, providing high-speed cutting and high torque output, and at the same time, with user customized options, to meet the needs of large-volume and one-piece-small-lot production, to ensure the safety and efficiency of operation and machining.

- Max. diameter of boring: ∅400mm

- Max. output torque of spindle: 28KN.m

- Max. feeding force of feed carriage: 80KN

Specifications | Unit | TK2140 |

Range of spindle speeds | rpm | 5~450 |

Max. output torque of spindle | KN.m | 28 |

Max. feeding force of feed carriage | KN | 80 |

Feed speed range of feed carriage | mm/min | 0~5000 |

Diameter range of bore | mm | ∅50~155 |

Max. diameter of boring | mm | ∅400 |

Machine weight of 3 meters | Kg | 35 |

Add weight per meter | Kg | 1000 |

Machine size | mm | 13850*4300*2300 |

Features

Electric servo bending machine realizes fast response and precise control through electric servo system, which improves productivity, reduces energy consumption, and lowers noise pollution. Its high-precision positioning capability ensures machining quality while reducing maintenance costs and enhancing the safety of the working environment.

- Transmission and feeding system: double rack and pinion transmission, the feeding system is driven by servo motor to ensure transmission precision and large torque.

- Drive: Workpiece jacking and drill box feeding are driven by servo motors, providing large feeding force to realize powerful boring;

- Wide Frequency AC Inverter Motor: The spindle box and drill box spindle are driven by an inverter motor, providing a wide speed range and high torque.

- Workpiece clamping and support: the front end of the workpiece is tightened by the top plate with chip discharge port; the spindle head is designed as a C-type spindle head with quick-change function, which is easy to assemble and disassemble; the middle part is equipped with a bracket or a center frame for lifting up the workpiece, which provides stable support for the workpiece; the rear end of the workpiece is tightened by the top plate on the oiler and serves as sealing function.

- Chip Discharge Mode: Adopting external chip discharge mode, suitable for all kinds of mass production.

- Safety and protection: the top tightening of the workpiece and the feeding movement of the drill box are driven by front and rear servo motors, and the item tightening realizes the current overload protection, which is safe, reliable and easy to operate: the feeding force is large when feeding, which is easy for powerful boring.

Applications

- CNC deep hole drilling machine can not only bore holes, but also perform rolling processing to achieve surface roughness of Ra0.4. It is suitable for the processing of through holes, blind holes and stepped holes of shafts, which is suitable for the demand of mass production and also adapts to the production of single piece and small batch.

- Widely used in aerospace, automotive, machinery manufacturing, oil and gas, mold manufacturing, energy, medical equipment, electronics and construction industries, it is the key equipment to achieve high-precision deep hole machining.

Related Products

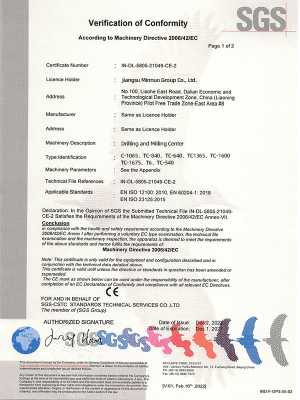

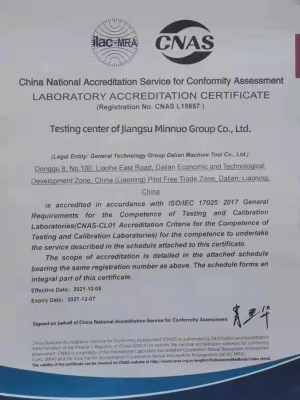

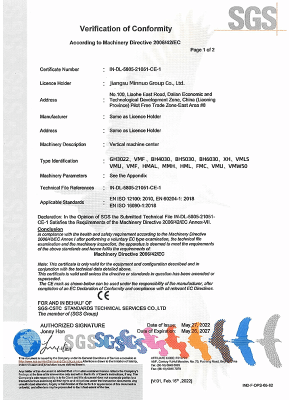

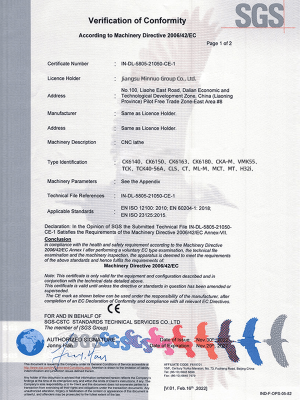

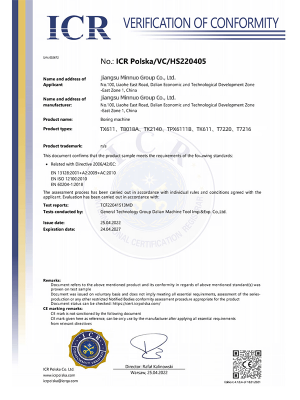

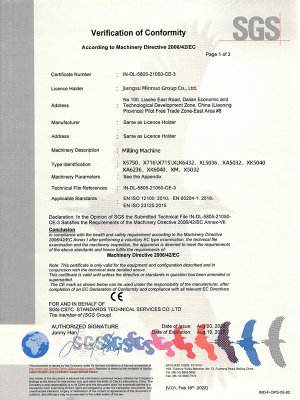

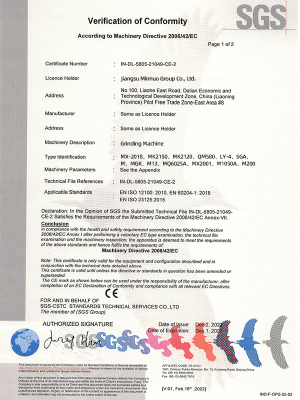

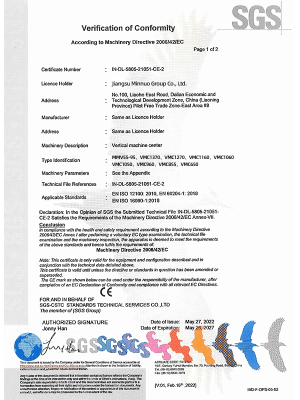

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com