PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

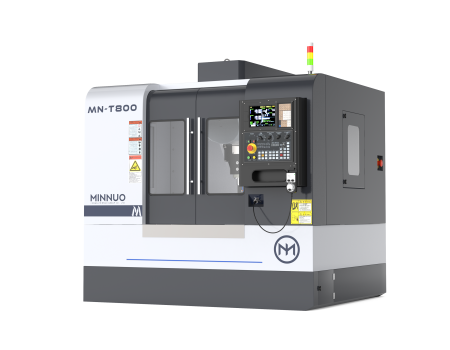

Drilling and Tapping Machining Centres TC-1065

The TC1065 High Speed Drilling, Milling and Tapping Centre is a machine developed on the basis of internationally popular, advanced and flexible machine design concepts, designed for drilling, tapping, boring and milling operations on non-ferrous metals, aluminium substrates and other materials. With fast traverse speeds and high spindle speeds, this model offers more than twice the drilling and tapping efficiency and quality of conventional machining centres, and is particularly suited to the cavity machining needs of the 3C products and communications industries.

- Bench size (length and width): 1100x650mm

- Triaxial stroke (X / Y / Z): 1000/650/300

- Maximum carrying capacity: 450kg

- Main shaft speed: 20000rpm

Name | Unit | Parameter | |

Range of work | Triaxial stroke (X / Y / Z) | mm | 1000/650/300 |

The distance from the spindle center line to the column guide rail surface | mm | 716 | |

The distance from the main nose to the working top | mm | 150~450 | |

Workingbench | Bench size (length and width) | mm | 1100×650 |

Maximum carrying capacity | kg | 450 | |

T-type groove (slot number, slot width spacing) |

| 5x14x120 | |

principal axis | main shaft speed | rpm | 20000 |

taper hole of spindle |

| BT30 | |

Power of spindle motor | kW | 3.7/5.5 | |

Speed | Fast moving speed (X / Y / Z axis) | m/min | 30/48/48 |

Cut into give speed | m/min | 10/10/10 | |

Tool magazine | Number of knives | grasp | 21 |

Tool maximum diameter / length / weight of |

| φ 60mm/200mm/3kg | |

Maximum diameter (full / adjacent) | mm | 60/80 | |

Machine tool accuracy | Positioning accuracy (X / Y / Z) | mm | 0.01 |

Repeat positioning accuracy (X / Y / Z) | mm | 0.006 | |

Else | Gas source / air pressure |

| 280L/min 6~8bar |

Total electrical capacity of the machine tool | KVA | 15 | |

Water tank volume | L | 220 | |

Machine Exsize (XYZ) | mm | 2700x3220x2900 | |

Machine tool weight (approx.) | kg | 4000 | |

Features

- TC-1065 machine base, table, column, crossbeam, slide saddle and spindle box are made of resin sand molding HT300 strength pregnant cast iron, which is processed by secondary annealing, completely eliminating casting stress and internal stress generated by rough machining, to ensure the structure of high rigidity and high stability qualitatively, and at the same time, to ensure the quality of the processed products.

- Standard 20,000 rpm spindle does not need to be equipped with an oil cooler for spindle cooling, but can be equipped with an optional circulating oil cooler system, which reduces the phenomenon of temperature rise generated by the high-speed rotation of the spindle, and allows the spindle temperature to be always 2 degrees lower than the room temperature under the differential temperature mode to prolong the life of the spindle and its precision.

- Minnuo lathe machine drilling and tapping machining centre series adopts imported ball screws and linear slide rails to ensure high rigidity and durability of the machine, guaranteeing greater load capacity and prolonging the service life of the machine.

Applications

- The TC-1065 drilling and tapping centre is mainly used for drilling and tapping holes in non-ferrous metals, aluminium substrates and other materials, as well as for boring and milling operations.

- Widely used in aerospace, ships, automobiles, machine tools, light industry, textile, electronics, general machinery, engineering machinery and almost all other industries.

| Order number | Host standard configuration |

| 1 | Main transmission system (including AC servo main motor, spindle, etc.) |

| 2 | X, Y, Z three-axis dragging system (including AC frequency conversion servo motor, coupling, ball wire rod, linear guide rail, etc.) |

| 3 | Main components (including base, bench, column, saddle, spindle box, etc.) |

| 4 | The numerical control system includes CNC cabinet, power module, servo module, PLC, operation unit, display, mobile hand pulse generator, heat exchanger, etc |

| 5 | Pneumatic triplet |

| 6 | Automatic lubrication system (including motor, pump, distributor, etc.) |

| 7 | Cutting fluid system (including motor, pump, chip flushing device and chip storage tray |

| 8 | X, Y and Z axis guide rail protection |

| 9 | Working light and warning lights |

| 10 | Random technical documents(Manual 1 set One set of qualification certificate and one set of packing list) |

In order to meet different market needs, we provide modular, customised solutions, the system uses the Mitsubishi CNC controller can also be upgraded to Fanuc, Siemens, can be any 4-axis combination of machining, there is a need to contact us.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com